Combined power engines

A combined power and engine technology, applied to combustion engines, machines/engines, mechanical equipment, etc., can solve problems such as engine stalling and affecting engine life, and achieve the effect of improving heat energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

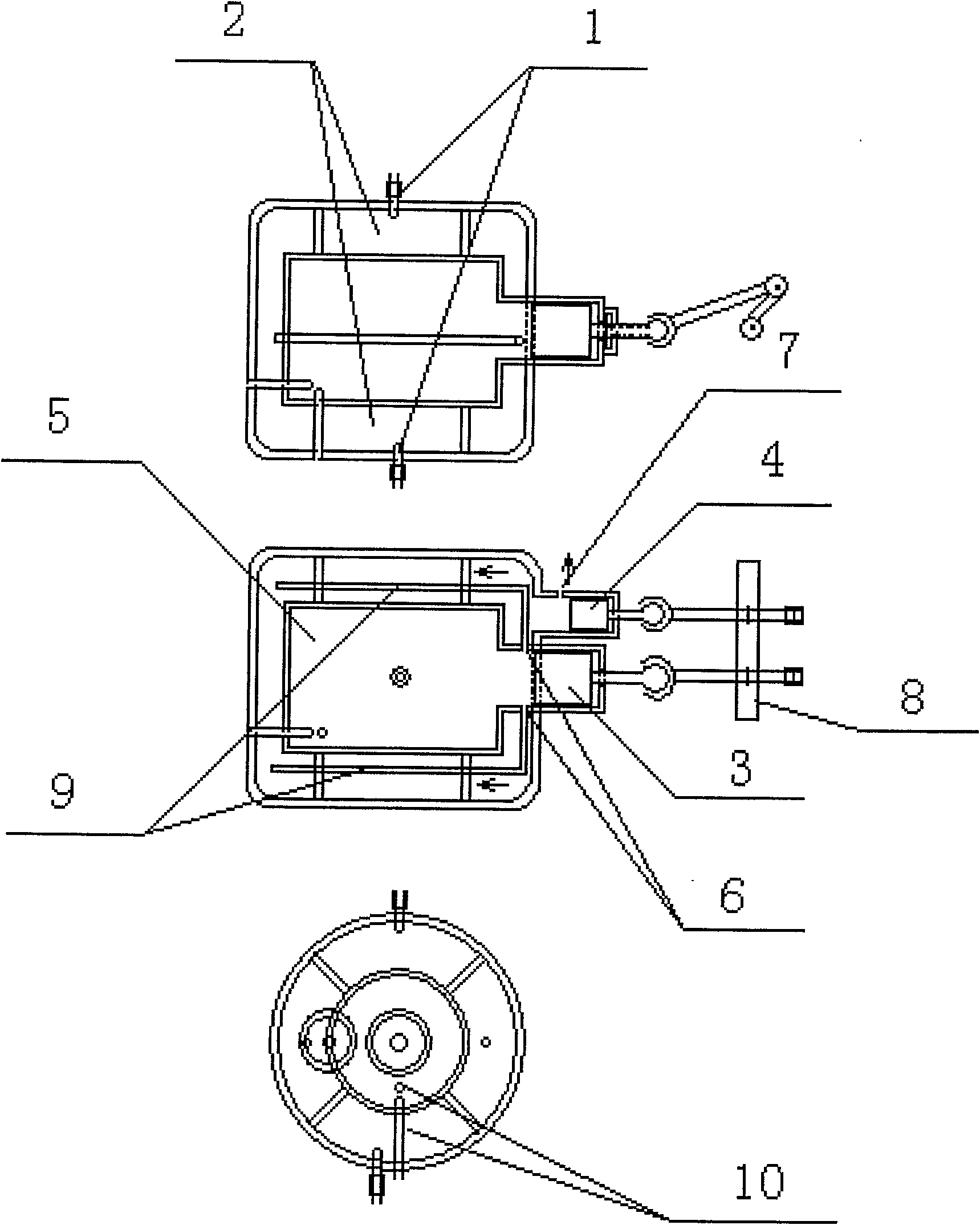

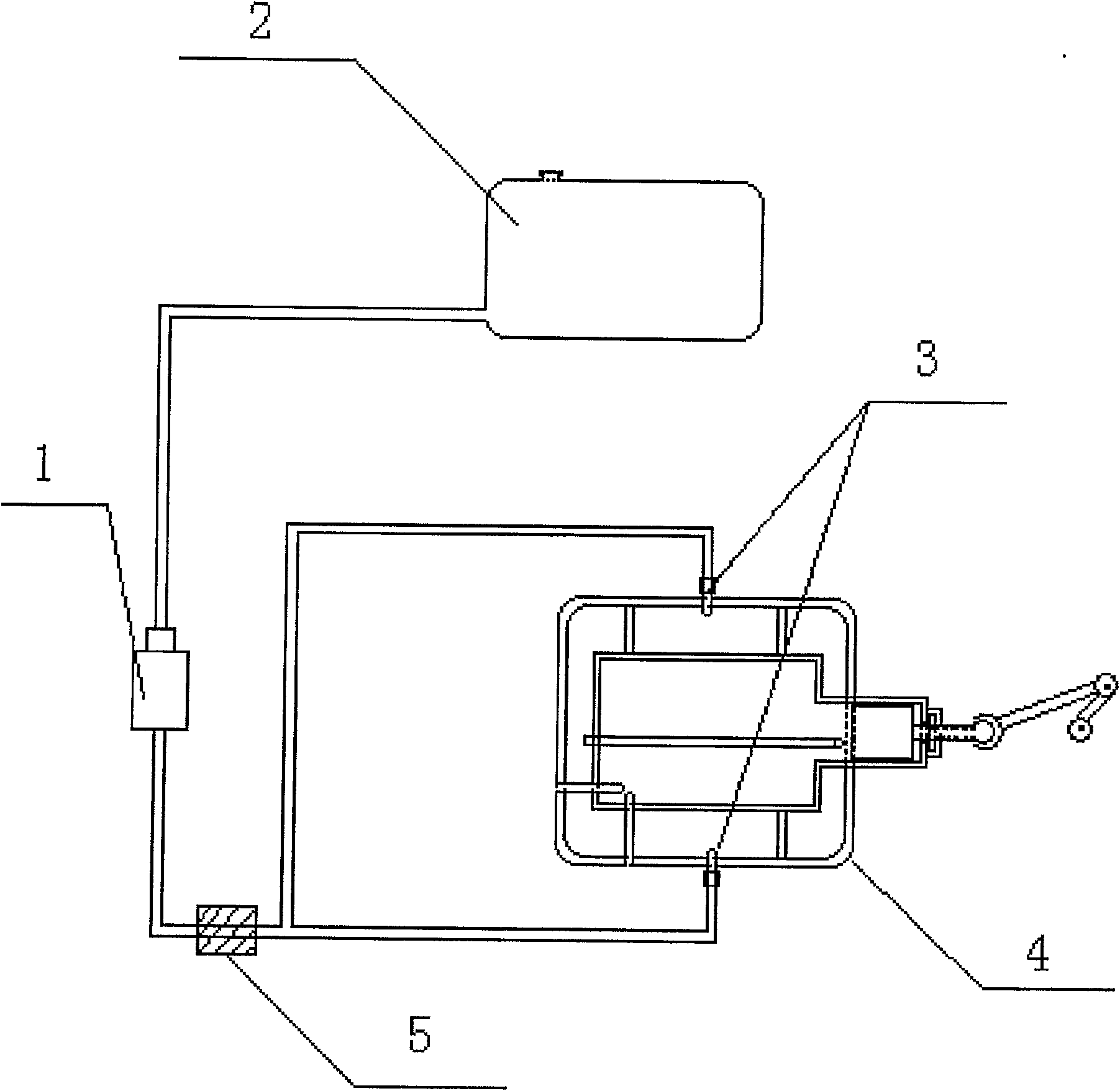

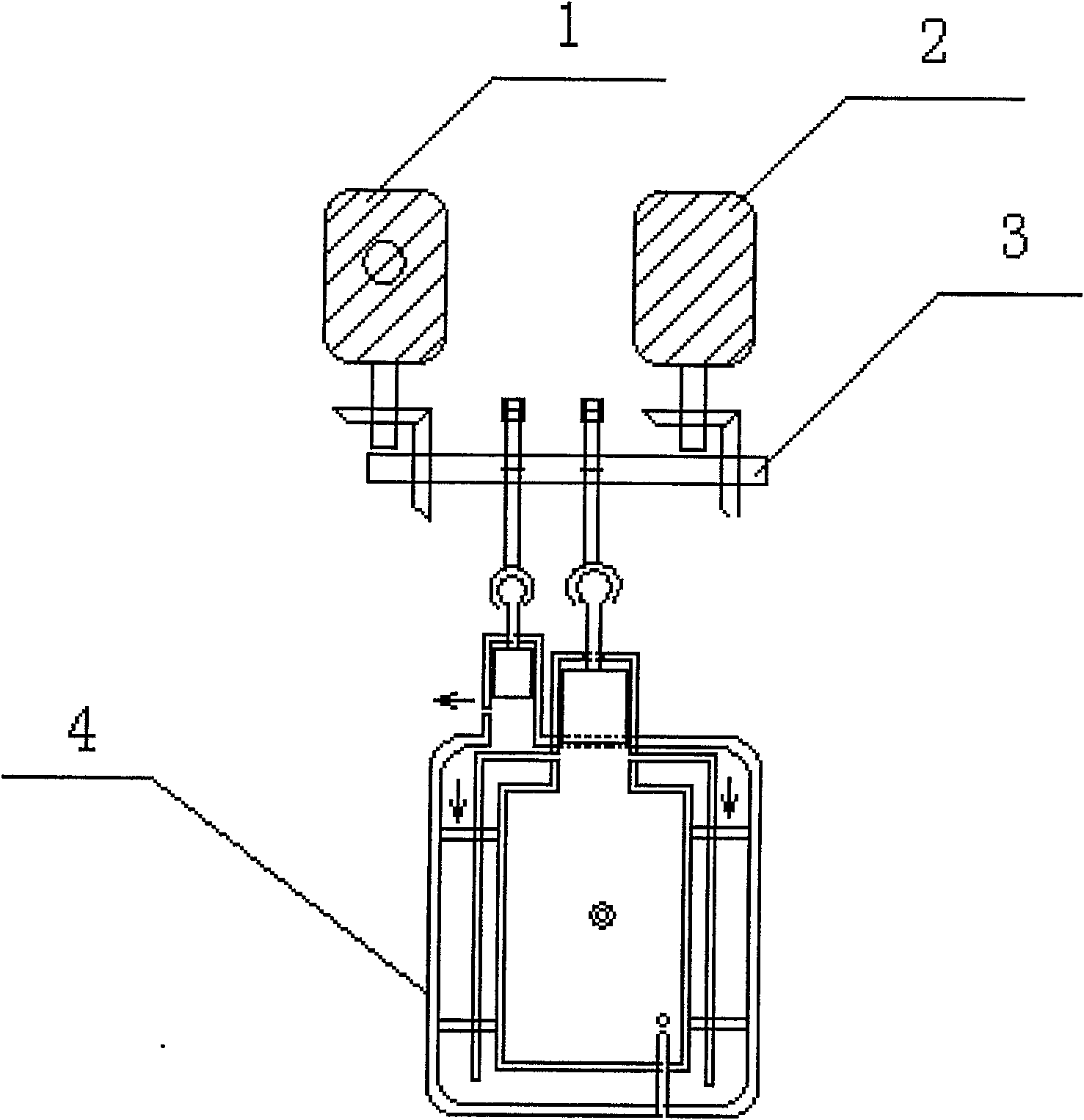

[0018] in the attached figure 1 Among them, after the combined power engine starts, the piston of the combustion cylinder completes the first stroke, and the high-temperature waste gas is discharged from the high-temperature exhaust gas outlet (6), and enters the tail of the steam generating cylinder (4) through the high-temperature exhaust gas conduit (9). At this time, the upper and lower water atomizers (1) spray water mist to the steam generating cylinder (4) under the control of the solenoid valve, and the water mist is instantly gasified under the action of high temperature, and the high-pressure steam pushes the steam cylinder piston (2) to move, Thereby drive rotating shaft (8) to rotate. The spark plug of the internal combustion cylinder and the fuel injection nozzle (10) are injected and burned under the control of the electromagnetic valve, which pushes the piston (3) of the combustion cylinder to move, thereby driving the rotating shaft (8) to rotate. The steam cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com