Coal gas pipeline leakage iron box wrapping method

A technology of gas pipelines and iron boxes, which is applied in the direction of pipe components, pipes/pipe joints/pipe fittings, mechanical equipment, etc., which can solve problems such as difficulty in closure, loss of economic benefits, unsafe welding, etc., and achieve the possibility of preventing the existence of explosive gases , Great economic value, and the effect of reducing flammability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The steps of the method for repairing the leaking iron box of the gas pipeline of the present invention are:

[0028] 1) Make a wedge-shaped cork with a diameter similar to the leak point, wear a gas mask and drive the cork into the leak point;

[0029] 2) Apply sealing paste on the gap between the cork and the leak;

[0030] 3) Determine the size of the iron box according to the size of the leak point and the degree of corrosion of the pipeline around the leak point, and make an iron box with an opening that fits the pipe. At the same time, there are air inlets and exhaust ports on the iron box. One intake valve and one exhaust valve are installed on the air port;

[0031] 4) Invert the prepared iron box on the leak point. In order to reduce the volume of the iron box, the iron box can be filled with paste in advance, and it is advisable to not exceed 3 / 4 of the volume of the iron box;

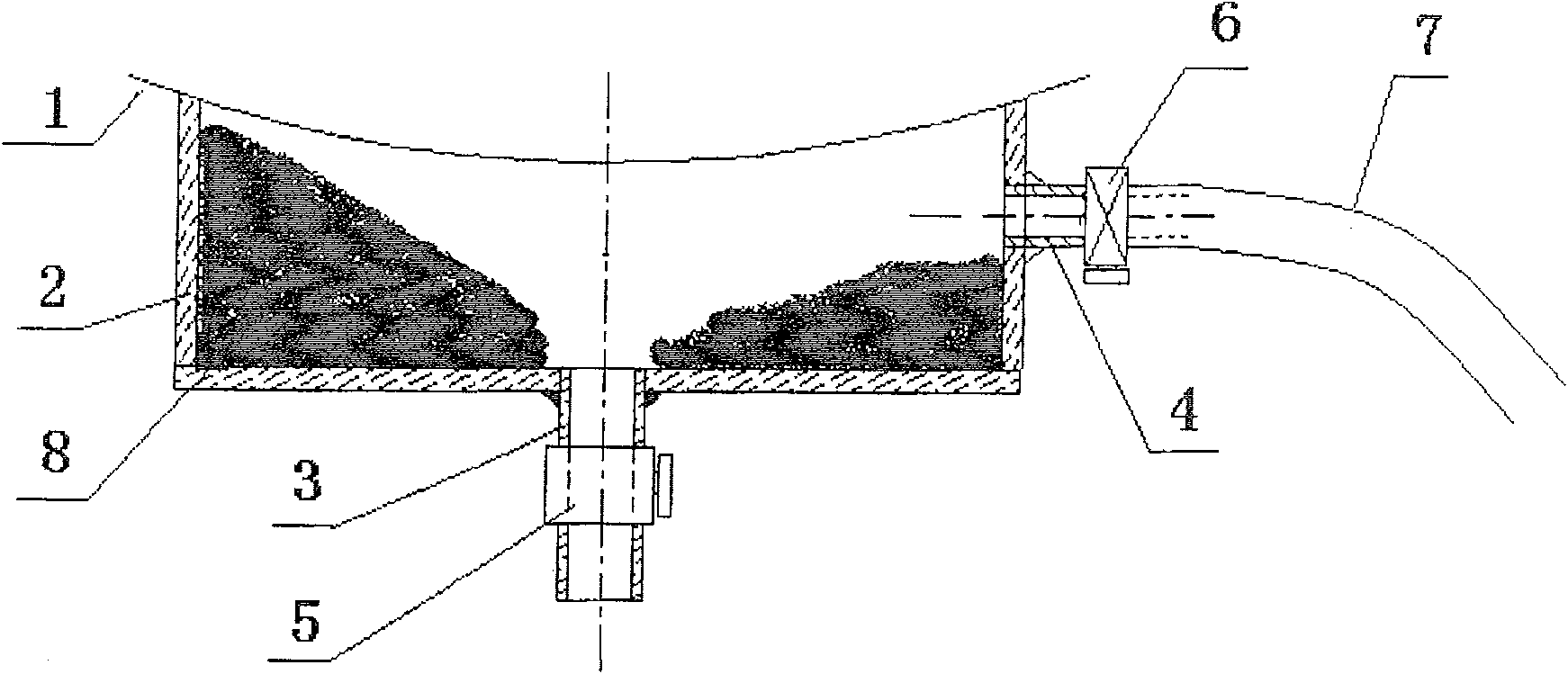

[0032] figure 1 It is a schematic diagram of the iron box used in the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com