Motor based on direct piezoelectric impact rotation

A piezoelectric and direct technology, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., which can solve the problems of affecting service life, unstable long-term operation, and difficult structure. , to achieve the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

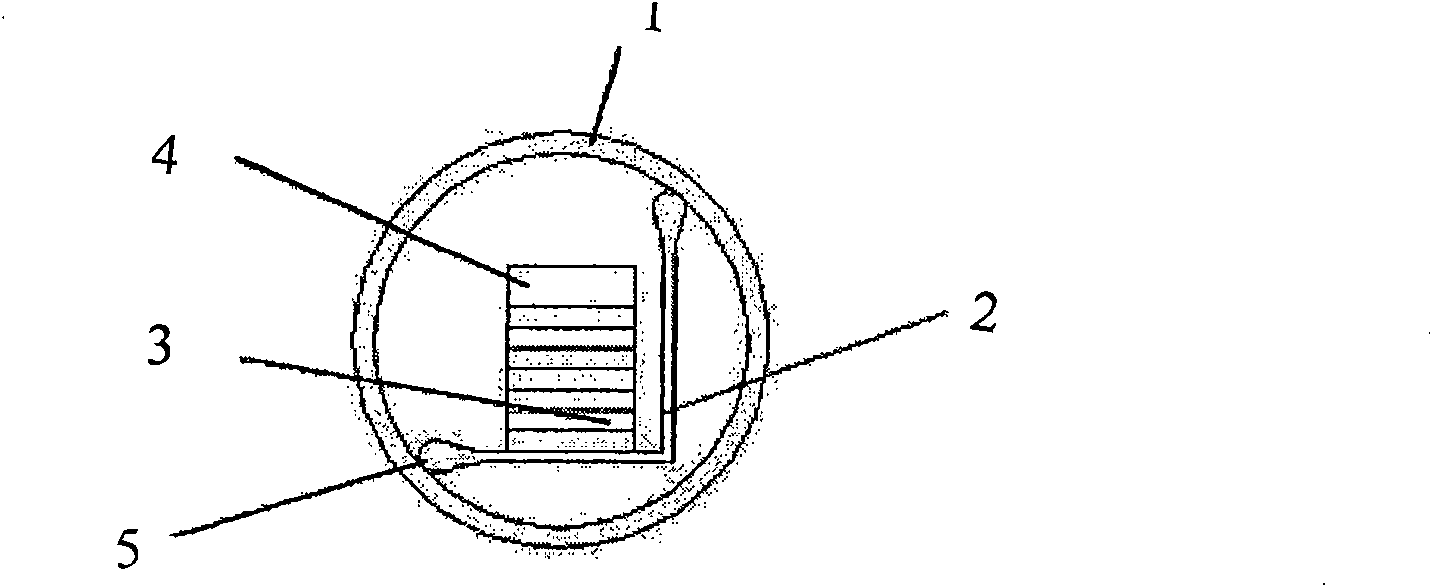

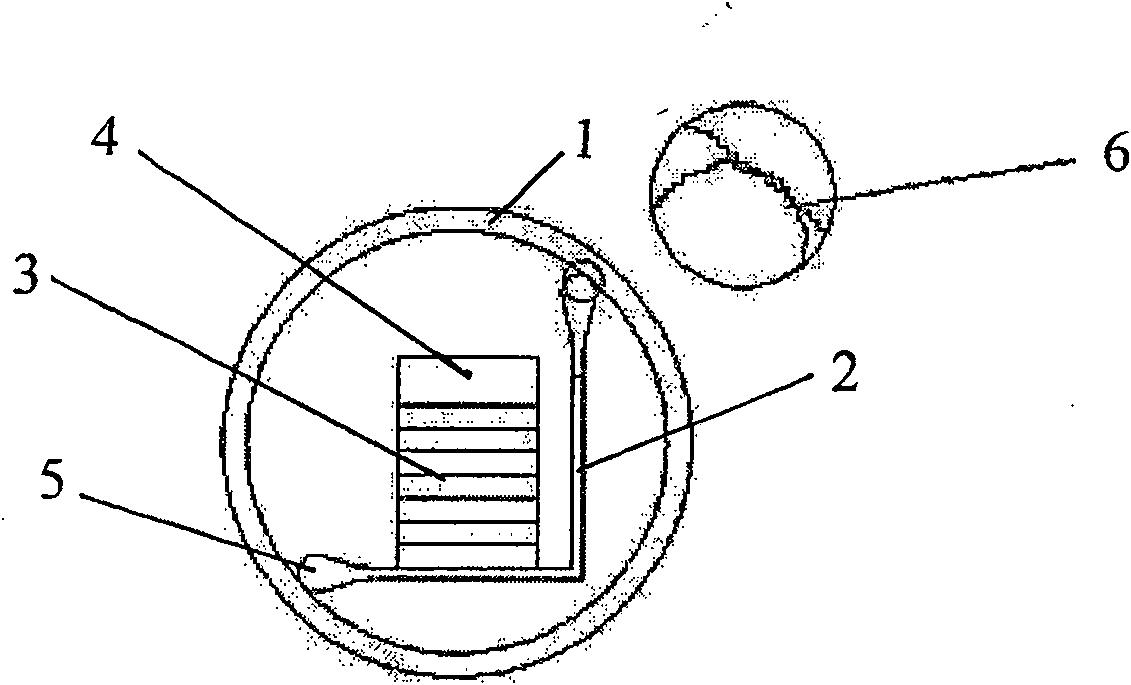

[0016] Such as figure 1 As shown, the present invention includes an outer ring 1, an L-shaped elastic rotor 2 and a piezoelectric stack 3 stacked on an inner side of the L-shaped elastic rotor 2; The electric impact energy and the cogging rotation of the entire inner circle of the outer ring 1 rotate.

[0017] The mass block 4 is arranged on the piezoelectric stack 3 to increase the inertial impact capability, so as to improve the efficiency of motor rotation.

[0018] The L-shaped elastic rotor 2 is made of elastic material with equal length on both sides, such as spring steel sheet.

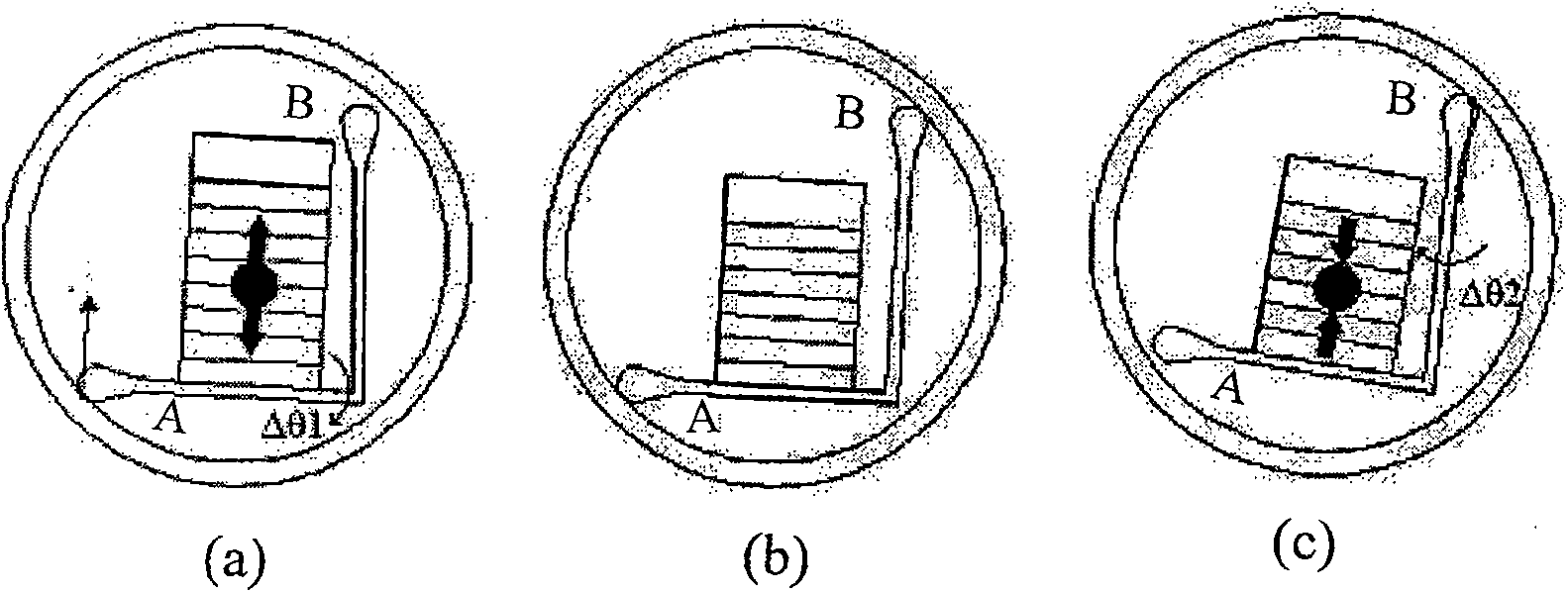

[0019] The ultrasonic motor is composed of an outer ring 1, an L-shaped elastic rotor 2, and a precisely controlled piezoelectric stack 3. The two end points (A, B) of the L-shaped structure are not fixedly connected to the outer ring 1, and high-precision matching tooth grooves are made on the end points and the outer ring 1 to reduce the gap between the outer ring 1 and the inner L-shaped e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com