Magnetic current changing polishing device for large caliber aspheric surface optical part

A technology of magnetorheological polishing and optical parts, applied in the field of magnetorheological polishing, can solve the problems of limited processing methods, inability to guarantee, long processing time for large-sized optical parts, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

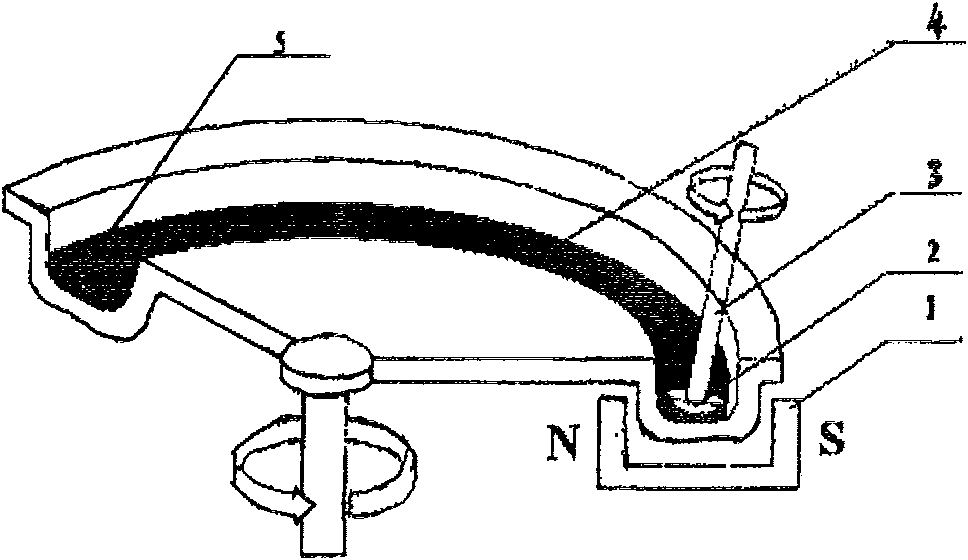

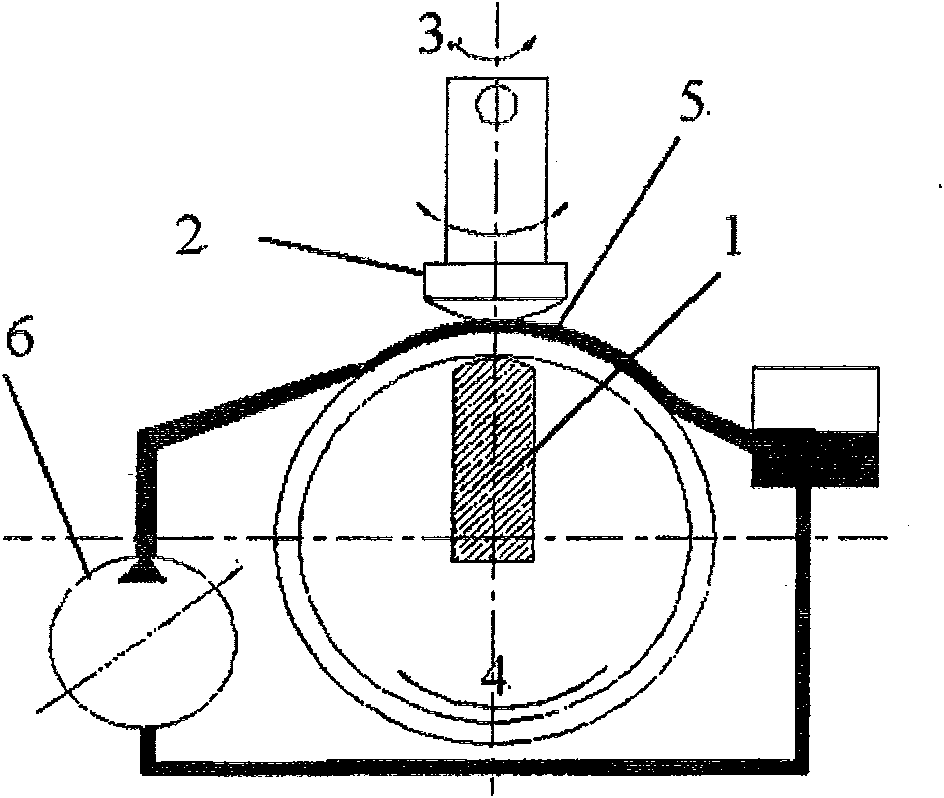

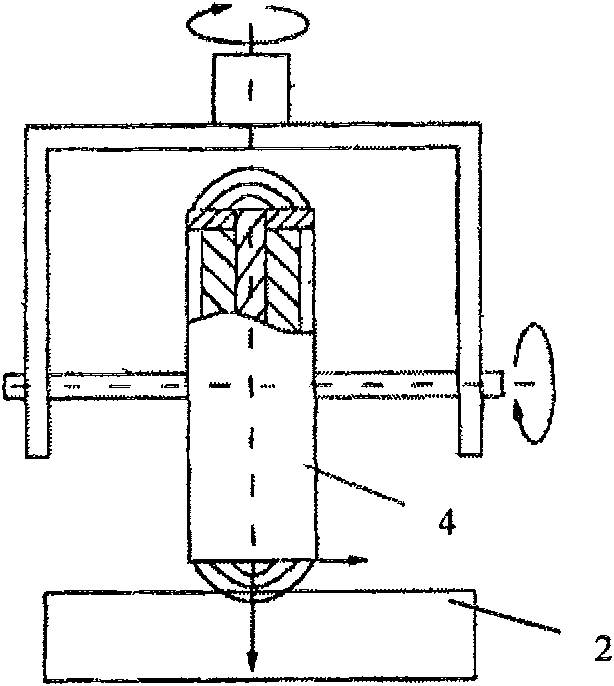

[0068] Such as Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 and Figure 14 Shown, a kind of magneto-rheological polishing device of the present invention is used for large aperture aspherical optical parts, and it comprises machine tool 1, polishing device 2, is used for providing the magneto-rheological polishing liquid circulating system 3 of stable performance polishing liquid and with In the control system where the above components are connected, the machine tool 1 has four or more degrees of freedom, and the polishing device 2 is fixed on the machine tool 1 and is located directly above the workpiece to be processed on the machine tool 1 .

[0069] see Figure 10 , Figure 11 and Figure 12 As shown, in this embodiment, the polishing device 2 includes a double-shaft support mechanism 201 and an inverted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com