Three-dimensional computerized numerical control sawing machine

A sawing machine, three-dimensional technology, applied in the field of three-dimensional CNC sawing machine, can solve problems such as constraints, achieve accurate and reliable synchronous transmission, and clean operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below in conjunction with the accompanying drawings in the form of embodiments.

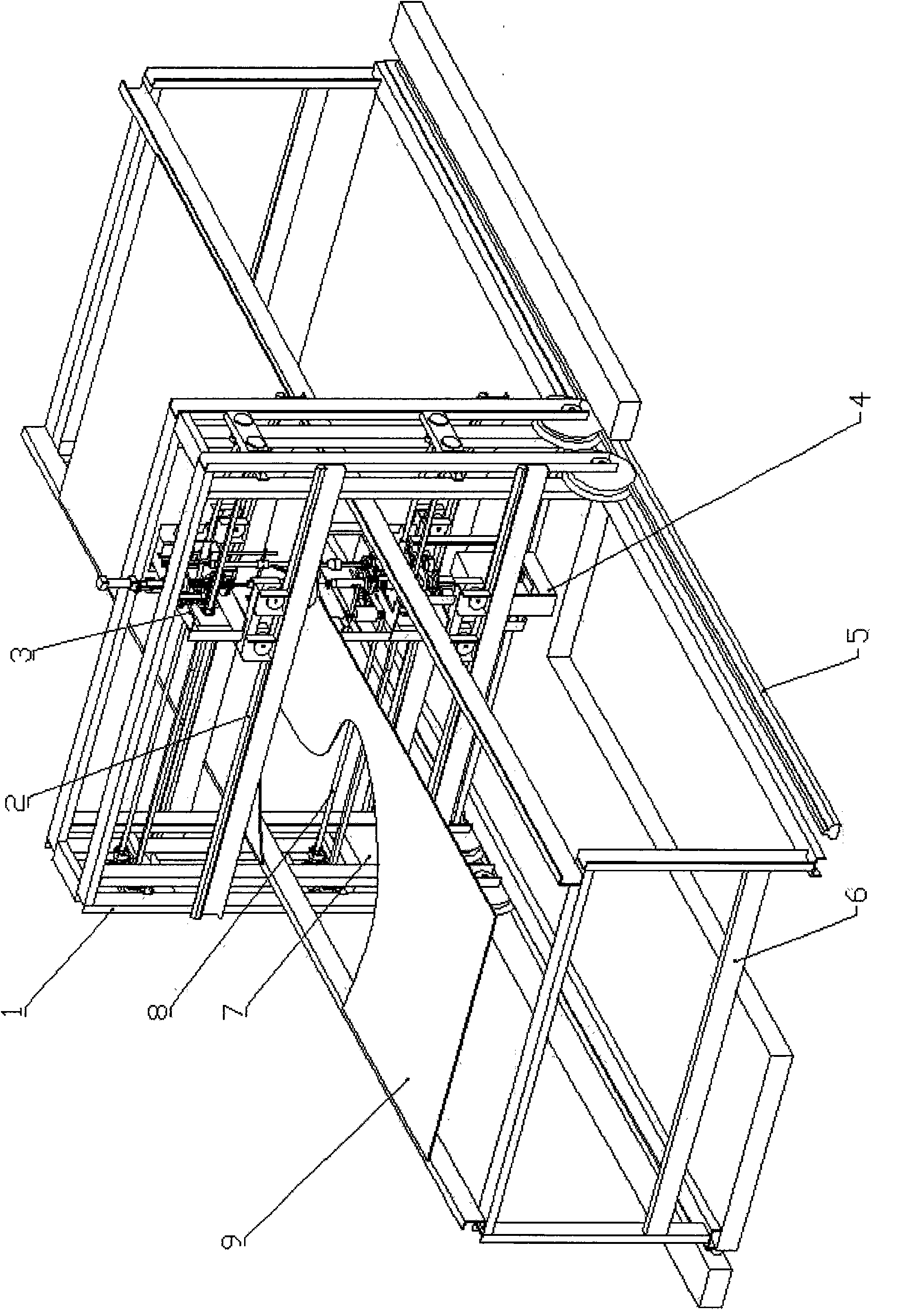

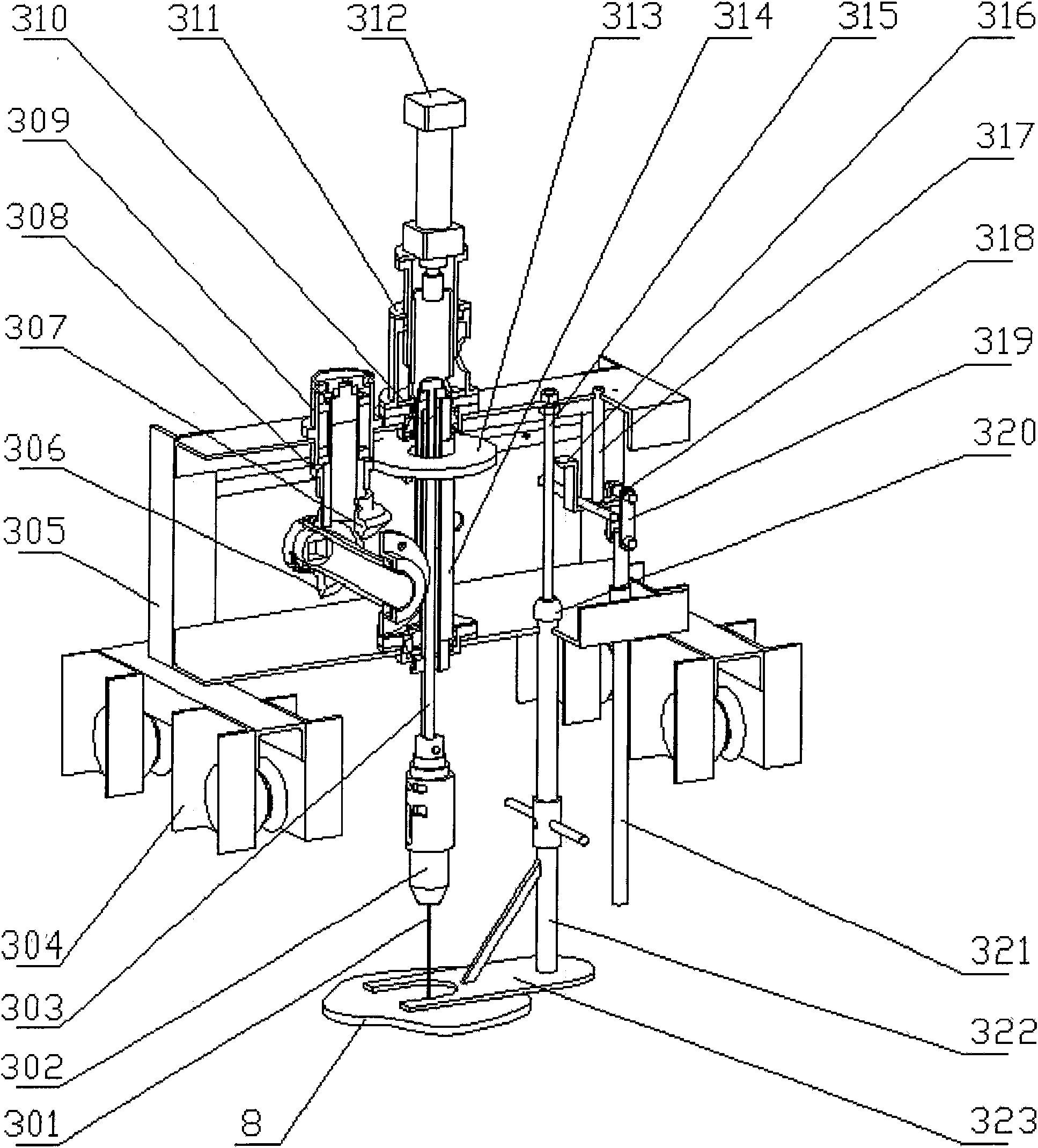

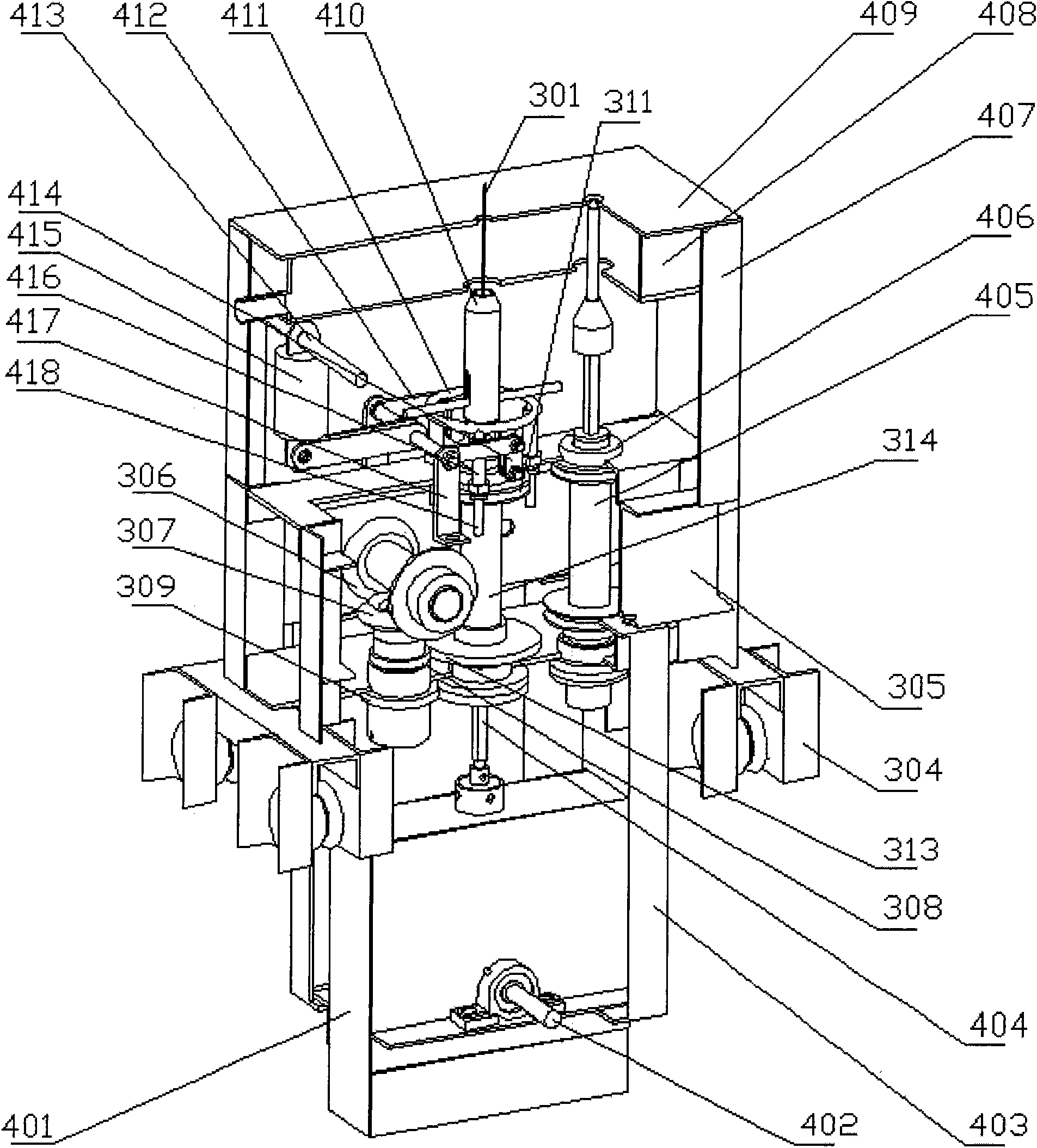

[0061] The frame 1 is connected by section steel into a rigid whole (can also be cast), the longitudinal guide rails 2 are installed on both sides of the frame 1, and the transverse guide rails 5 are fixedly installed under the frame 1 relative to the ground; the upper chassis 3 and the lower chassis 4 are respectively installed on On the longitudinal guide rail 2, the workbench 6 straddles the hollow part of the frame 1 and is fixed between the upper chassis 3 and the lower chassis 4 relative to the ground (the horizontal guide rail 5 and the workbench 6 can be integrated), and the processed object 9 Fixed on the workbench 6, the saw blade 301 is installed between the upper chuck 302 of the upper chassis 3 and the lower chuck 410 of the lower chassis 4 and is tensioned; the electric control system 7 is installed on one side of the frame 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com