Non-contact reading sensor of mechanical character wheel counter and its design method

A mechanical character wheel and counter technology, applied in the direction of counting mechanisms/items, instruments, etc., can solve the problems of no electronic digital output equipment, etc., and achieve the effects of high accuracy, long life and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Applied on 8 phototransistor sensors.

[0025] Design of support and circuit board:

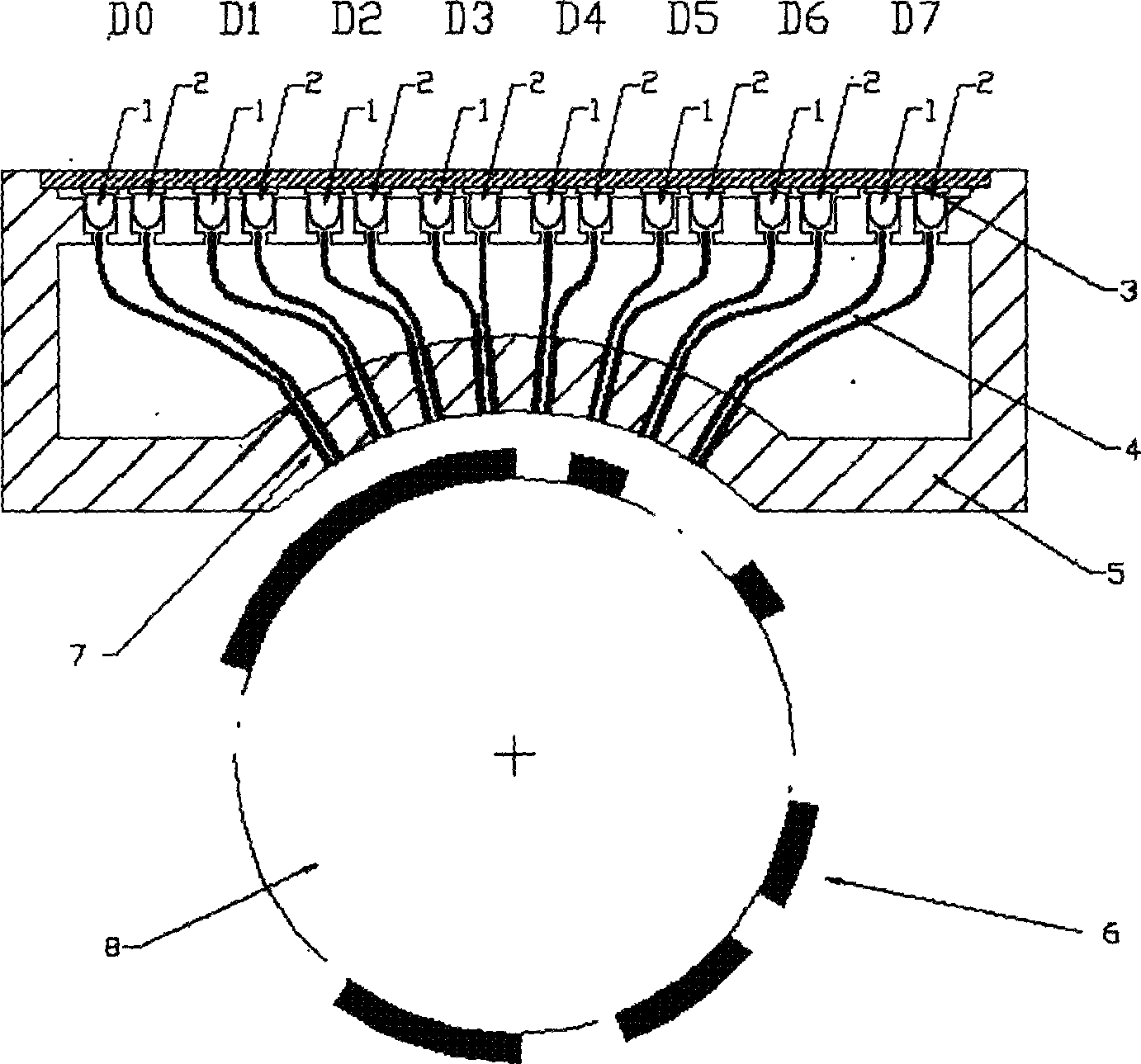

[0026] (1) Determine the number of phototransistors corresponding to each character wheel N=8 (see attached figure 1 );

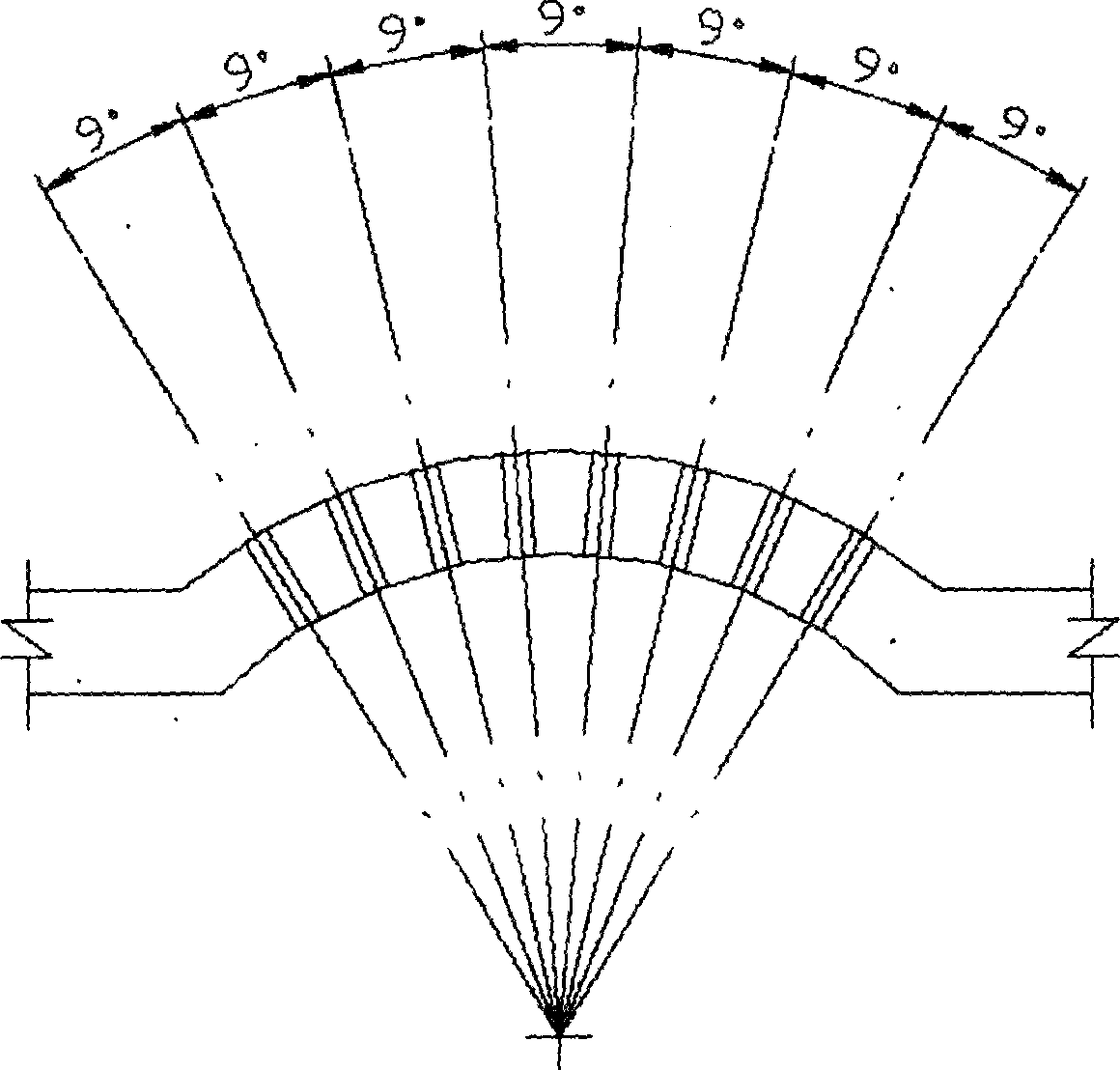

[0027] (2) Calculate the angle between two adjacent fiber fixing holes:

[0028] α=360÷[(8-3)×8]=9 degrees;

[0029] (3) The number of fiber fixing holes is 8, and the interval angle is 9 degrees (see attached figure 2 );

[0030] According to the above method, the bracket (5) and the fiber positioning hole (7) on the bracket (5) are designed, and the circuit board (3) is equipped with 8 phototransistors (see attached figure 1 ).

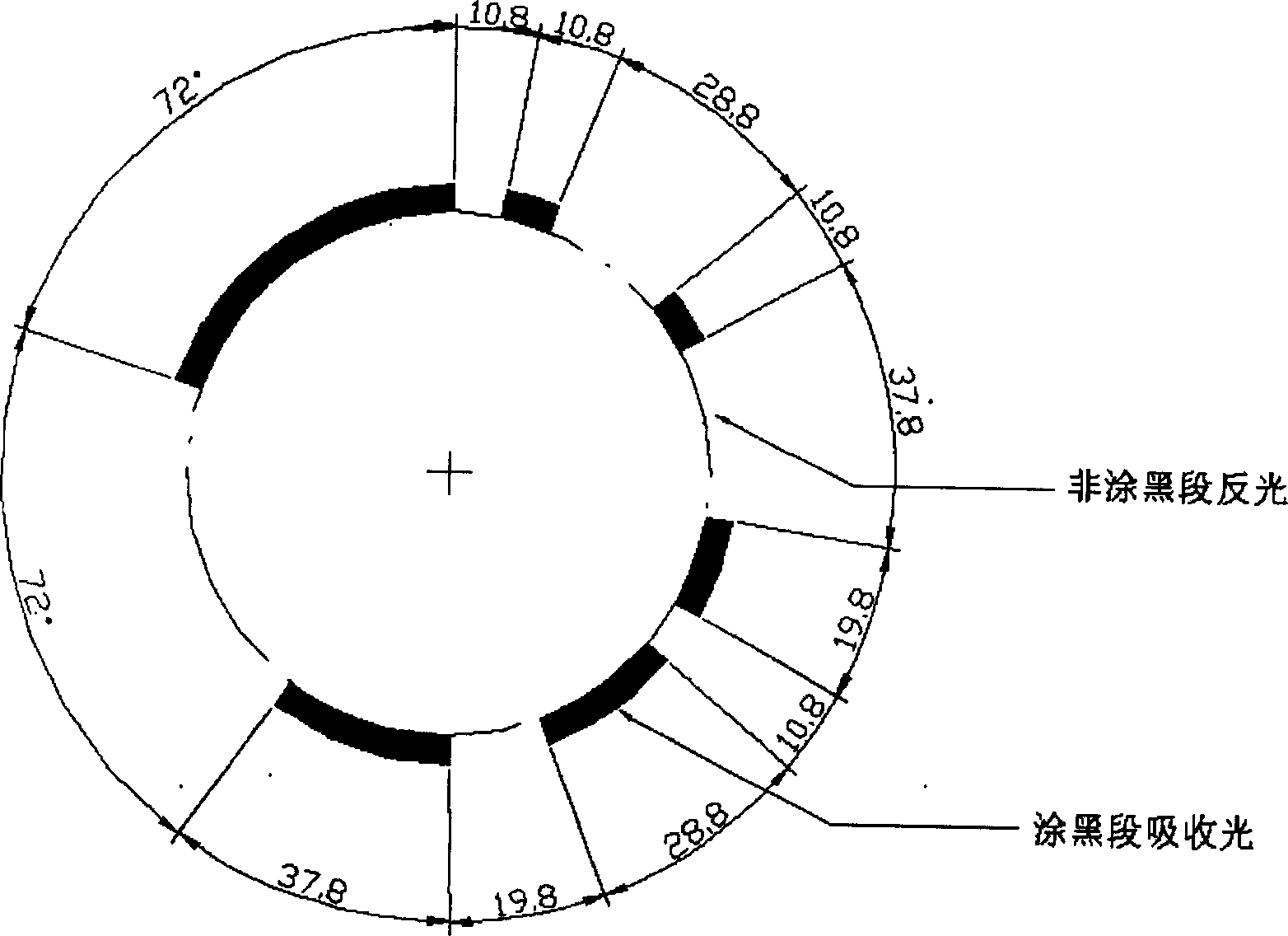

[0031] Design of reflective strips:

[0032] (1) The length of the reflective section and the non-reflective section is measured by the angle between the center of the character wheel;

[0033] (2) Calculation of the length of each section:

[0034] α MK =360×(K+1 / M)÷[(N-3)×N]

[0035] α 0 =360÷(N-3)

[0036] When N=8; M=5; K=1, 2, 3, 4, 5...

Embodiment 2

[0060] It is applied to 7 phototransistor sensors.

[0061] Design of bracket and circuit board:

[0062] (1) Determine the number of phototransistors corresponding to each character wheel N=7 (see attached Figure 4 );

[0063] (2) Calculate the angle between two adjacent fiber fixing holes:

[0064] α=360÷[(7-3)×7]=360÷28=12.9 degrees;

[0065] (3) The number of fiber fixing holes is 7, and the interval angle is 12.9 degrees (see attached Figure 5 );

[0066] According to the above method, the fiber positioning holes (7) on the bracket (5) and the outlet bracket (5) and the circuit board (3) are equipped with 7 phototransistors (see attached Figure 4 ).

[0067] Design of reflective strips:

[0068] (1) The length of the reflective section and the non-reflective section is measured by the angle between the center of the character wheel;

[0069] (2) Calculation of the length of each section:

[0070] α MK =360×(K-1 / M)÷[(N-3)×N]

[0071] α 0 =360÷(N-3)

[0072] When N=7; M=3; K...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com