Parallel-series six-freedom-degree operating platform for adjusting position of curved workpiece

A technology with curved surface workpieces and degrees of freedom, which is applied in the direction of manufacturing tools, metal processing equipment, welding equipment, etc., to achieve the effect of large bearing capacity, easy control and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

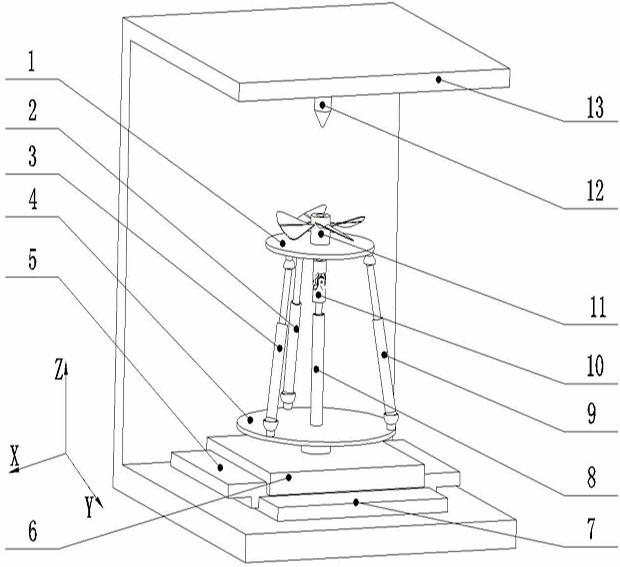

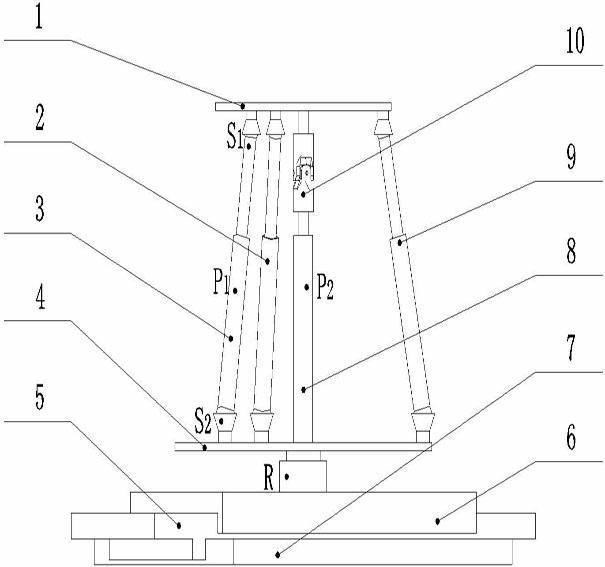

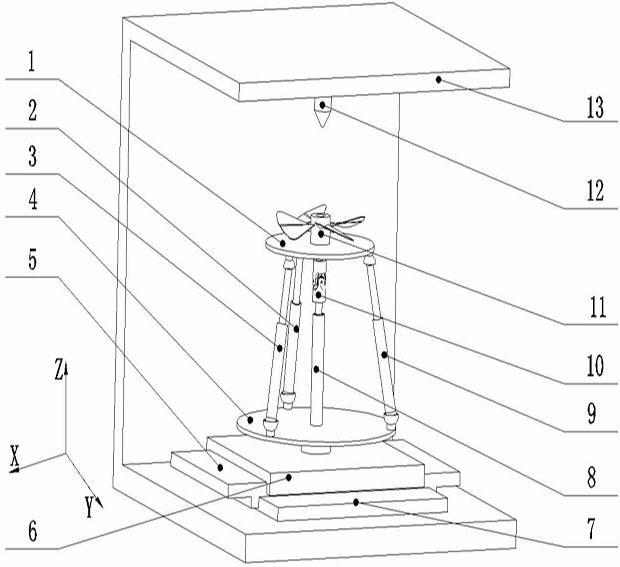

[0013] see Figure 1-2 , the present invention comprises a frame 13, the top of the frame 13 is a y-axis mobile platform 5 and an x-axis mobile platform 6 along the z-axis direction, on the bottom plate surface of the frame 13, a guide rail 7 is set along the y-axis direction, and on the guide rail 7 A y-axis mobile platform 5 is installed, and the y-axis mobile platform 5 moves back and forth along the guide rail 7 in the y-axis direction through the guide rail 7 . Similarly, guide rails are also provided along the x-axis direction on the upper surface of the y-axis moving platform 5 , and the x-axis moving platform 6 is installed on the guide rails of the y-axis moving platform 5 to realize back and forth movement in the x-axis direction.

[0014] The center position of the upper surface of the x-axis moving platform 6 is connected to the center position of the bottom surface of the rotating platform 4 through the rotating pair R along the z-axis direction. The upper part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com