A processing method and device for a shape-controllable 3D helical micro-antenna

A processing device, 3D technology, applied in the direction of coating, household appliances, household components, etc., can solve the problems of limited processing size, low processing efficiency and high cost of spiral micro-conductor, achieve unlimited processing size, easy device maintenance, The effect of saving production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

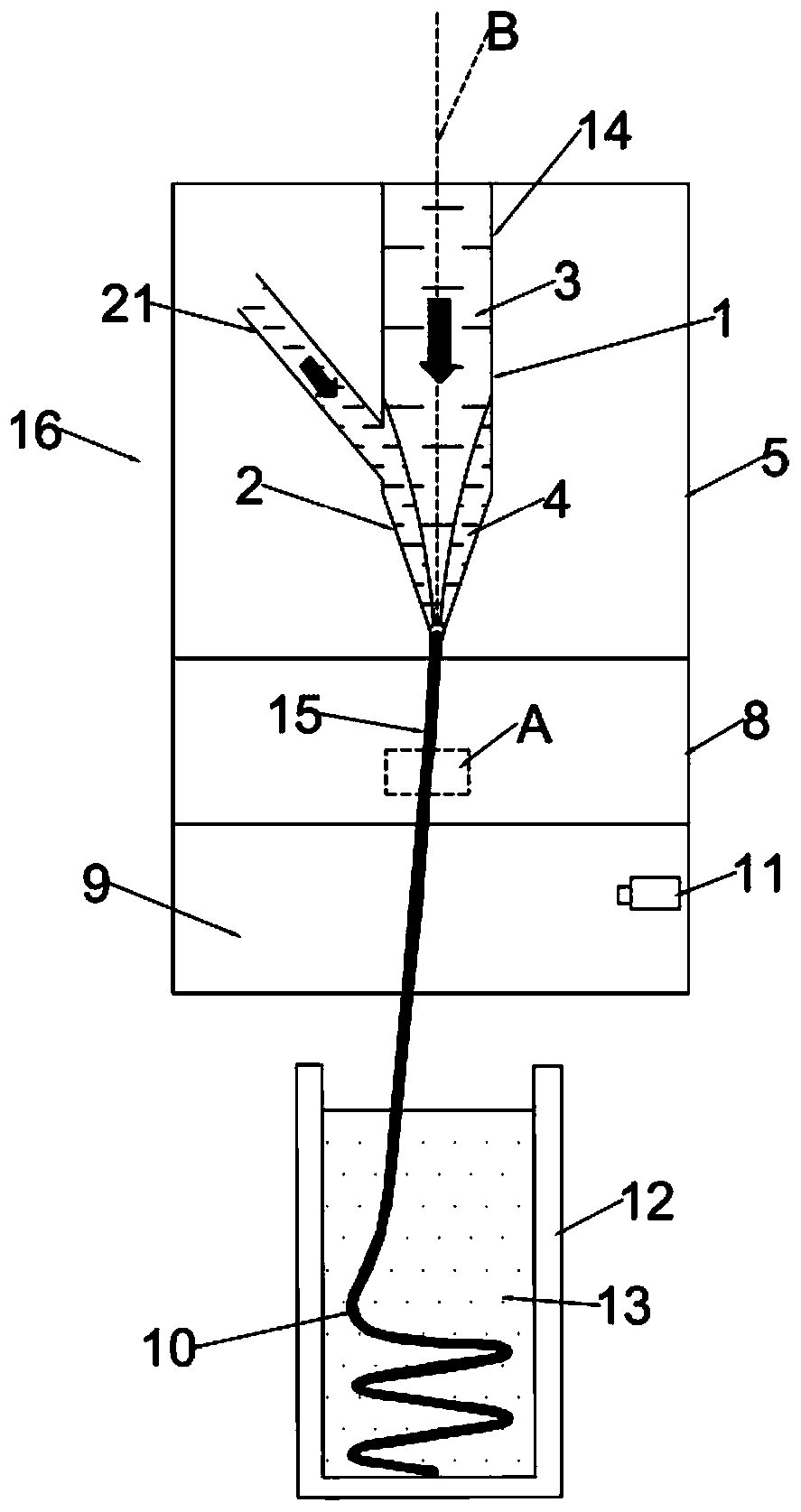

[0087] The outer tube 2 has a constriction diameter of 50 μm, and the inline tube 1 has a constriction diameter of 10 μm;

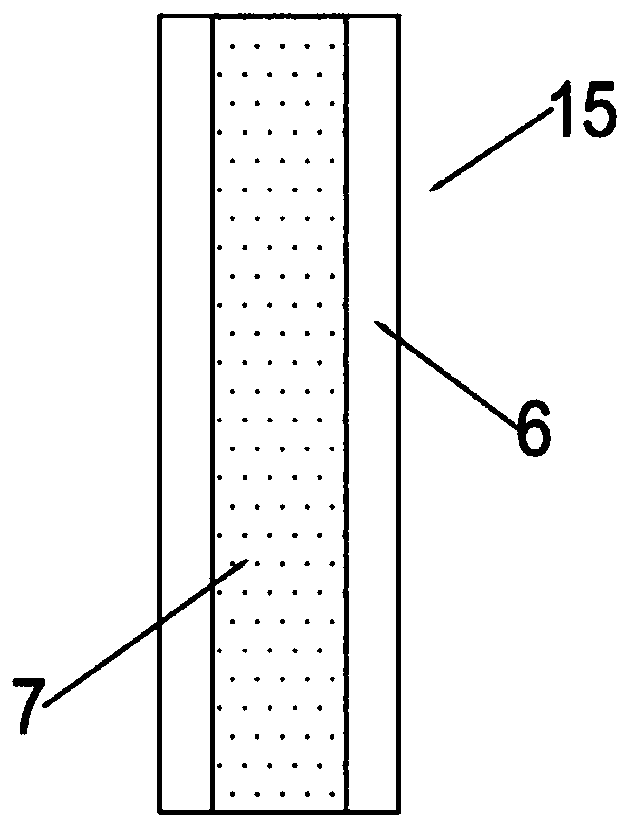

[0088] Apply a pressure of 54psi to the conductive paste, and apply a pressure of 55psi to the functional hydrogel, so that the conductive paste and the functional hydrogel are simultaneously extruded at a speed of 0.2mm / s to form a microwire 15; the wavelength is 405nm, and the power is 10mW of ultraviolet light cures the micro wire 15;

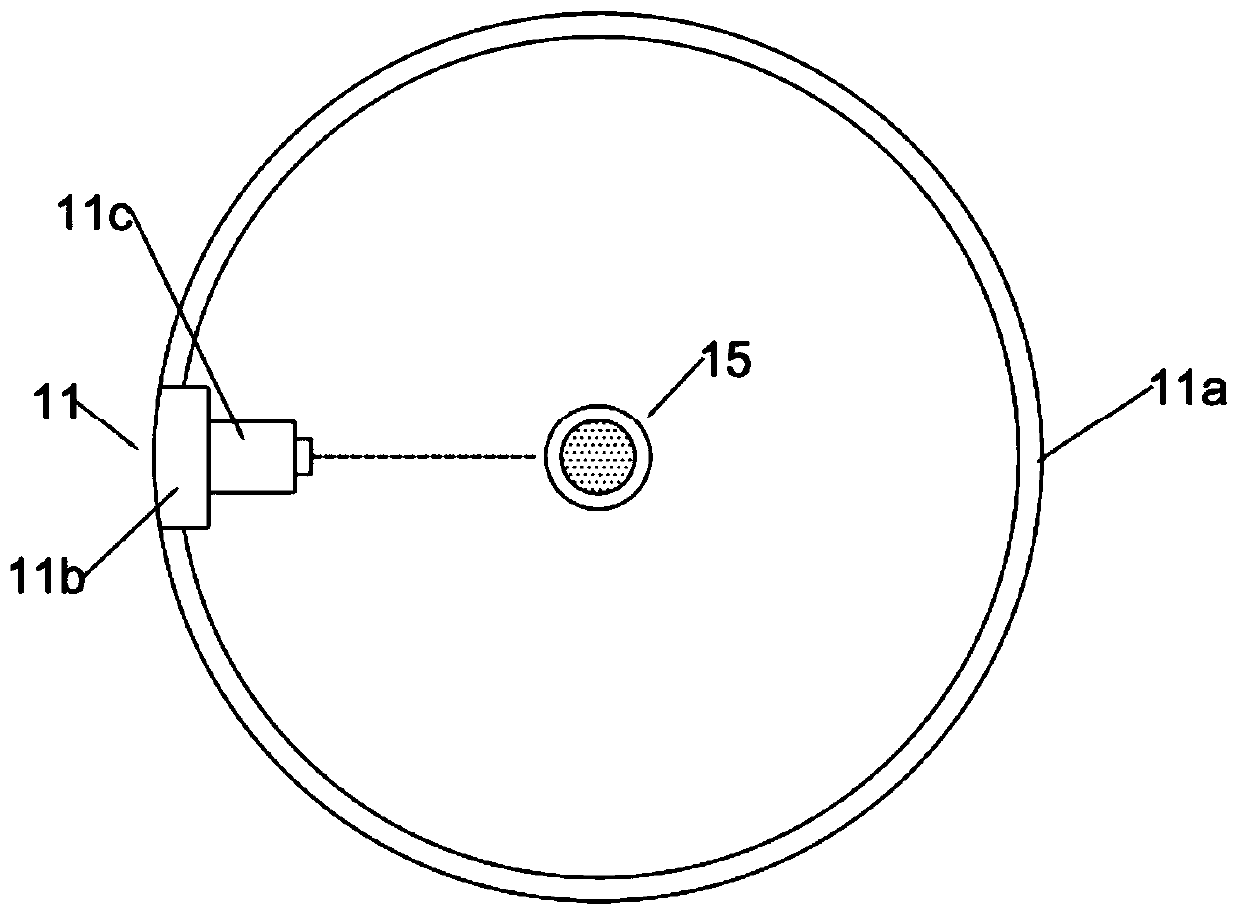

[0089] The rotating light source 11 aligns the micro wire 15 with a continuous wave laser with a power of 500mW, and rotates counterclockwise at a speed of 1rps. Such as Figure 4 As shown, an equal-diameter 3D helical micro-antenna 10 with a diameter of 5 mm and a pitch of 1 mm is shown.

Embodiment 2

[0091] The outer tube 2 has a constriction diameter of 50 μm, and the inline tube 1 has a constriction diameter of 10 μm;

[0092] Apply a pressure of 54psi to the conductive paste, and apply a pressure of 55psi to the functional hydrogel, so that the conductive paste and the functional hydrogel are simultaneously extruded at a speed of 0.2mm / s to form a microwire 15; the wavelength is 405nm, and the power is 10mW of ultraviolet light cures the micro wire 15;

[0093] The rotating light source 11 uses a continuous wave laser with a power of 500mW to align the micro-wire 15 with an acceleration of 0.1rps per second to rotate counterclockwise at a speed of 1rps and continue processing for 60s. The micro-wire 15 has a viscosity of 3.0k·mPa·s supporting solution 13 for centrifugal movement, forming such as Figure 5 As shown, a variable-diameter 3D helical micro-antenna 10 with a maximum diameter of 5 mm, a minimum diameter of 0.5 mm, and a pitch of 1.5 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com