Coal mining and digging machine

A planer and coal technology, which is applied in the field of coal mining planers, can solve the problems that the tension effect of the coal seam cannot be fully utilized, the structure of the drum shearer is complicated, the thickness of the coal seam is limited, etc. The effect of blockiness and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

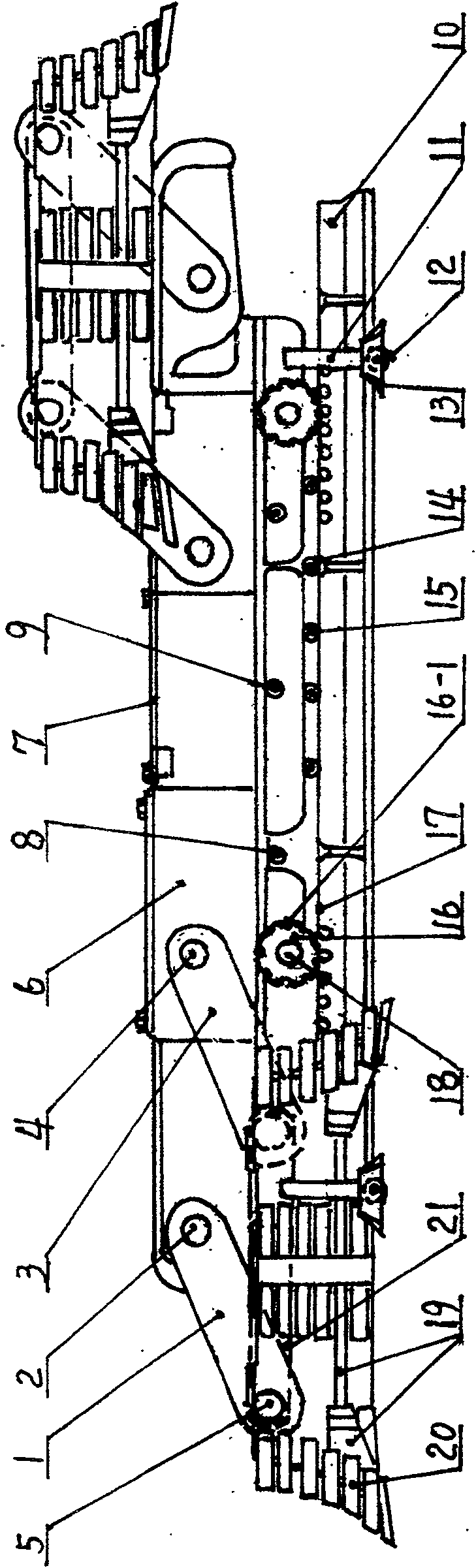

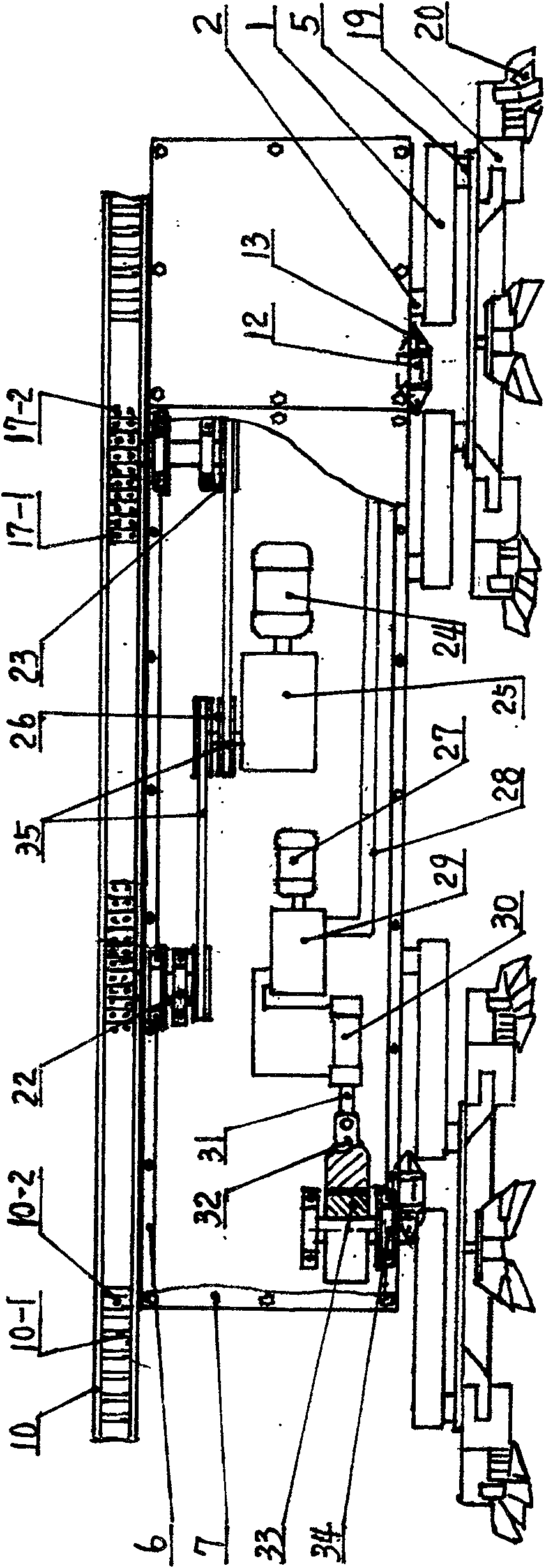

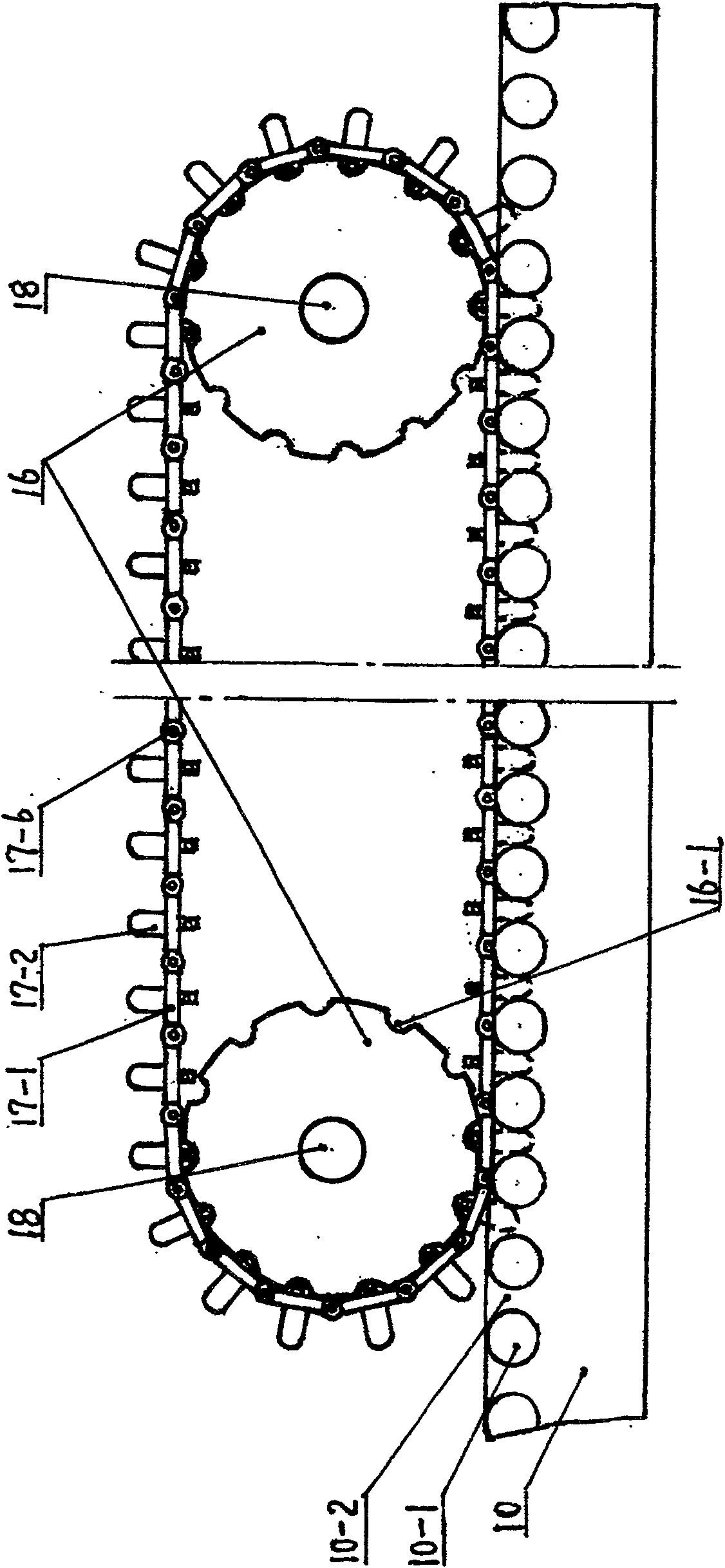

[0014] With reference to accompanying drawing, a kind of coal mining planer is made up of casing base 6, loam cake 7, traction motor 24, speed reducer 25, hydraulic system motor 27, hydraulic pump station 29, oil cylinder 30, planer 19 and planer 20, It is characterized in that two driving sprockets 26 are fixed on the output shaft of the reducer 25, and two transmission chains 35 are used to drive and connect the driven sprockets 23 fixed on the two driving shafts 18, and one is fixed at the outer end of the driving shaft 18. The traction pulley 16 of 13 U-shaped grooves 16-1 evenly distributed on the circumference; The drive crawler 17 is movably housed between the two traction pulleys 16; The drive crawler 17 (see attached Figure 4 , 5 6) It includes a tooth nail 17-2 fixed on the chain plate body 17-1, and the upper part of the tooth nail 17-2 is provided with a power shaft hole 17-4, and a power shaft 17-3 is fixed in the hole, and the chain plate body 17 Both sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com