Technique and apparatus for oiling silicon oil transformer

A technology of transformer and silicone oil, which is applied in the field of devices realizing the oil injection process of the silicone oil transformer, can solve the problems that the complete infiltration of the transformer oil cannot be guaranteed, affect the high performance and life of the silicone oil transformer, and reduce the probability of various failures and improve the operation Reliable, device combined with simple results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

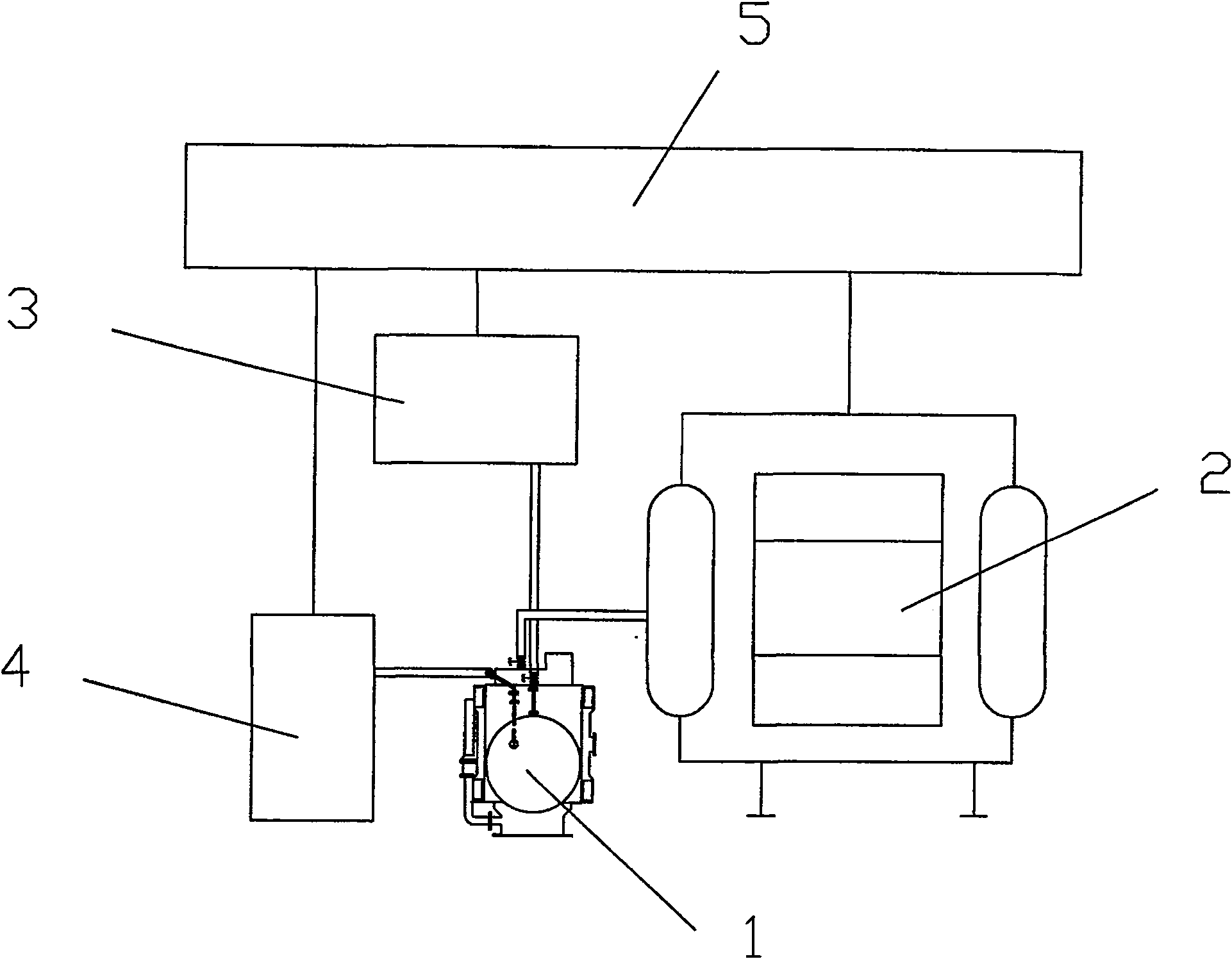

[0012] Referring to the accompanying drawings, the upper and lower valves of the transformer 1 are connected to the silicone oil treatment system 2 and the vacuum system 3 through a three-way pipe, the expander of the transformer 1 is connected to the pressurized static release system 4, and the PLC circuit control box 5 is connected to the pressurized static release system 4 It is electrically connected with the vacuum system 3 .

[0013] Referring to the accompanying drawings, dry the body of transformer 1 at a temperature of 100-130°C for 38-58 hours, and connect the upper and lower valves of transformer 1 with the silicone oil treatment system 2 and the vacuum system 3 through a three-way pipe to keep the temperature of the silicone oil at 60°C. ~70°C, through the upper and lower valves of the transformer 1, use the vacuum system 3 to pump the internal vacuum of the transformer 1 to below 100Pa, and fill the oil through the silicone oil treatment system 2. After the silicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com