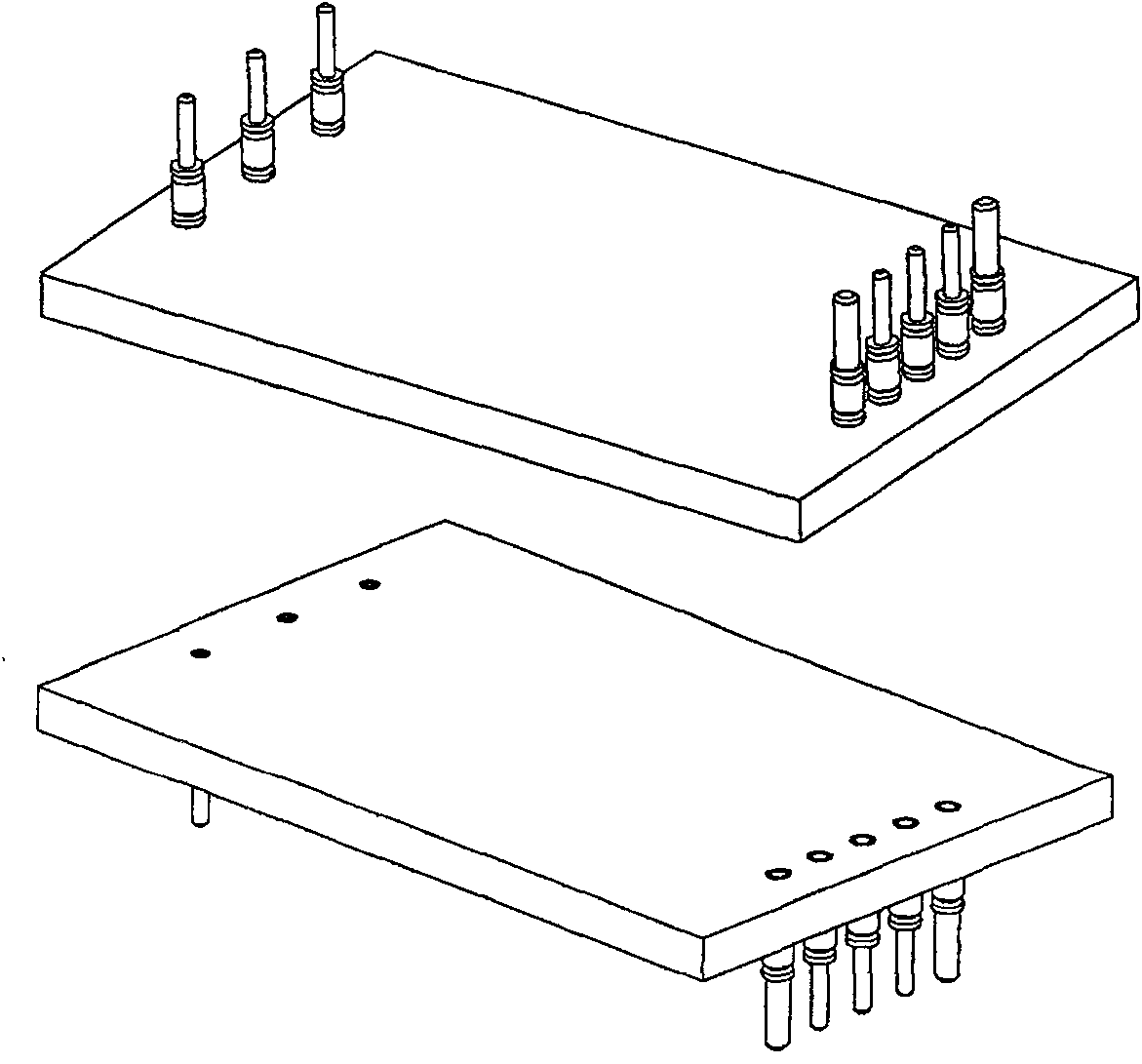

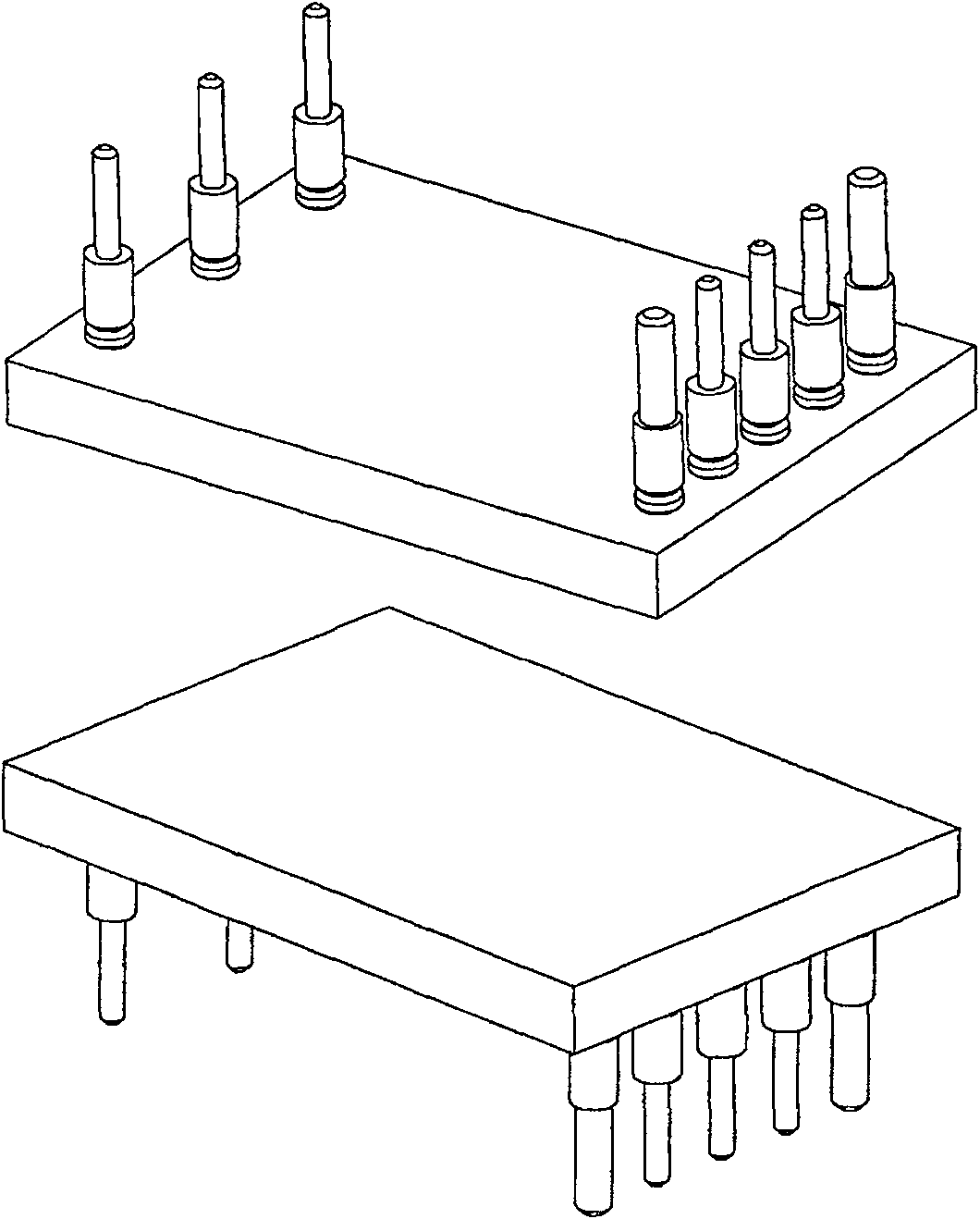

Module power supply pin structural parts

A module power supply and pin structure technology, applied in the direction of electrical equipment structural parts, electrical components, electrical solid devices, etc., can solve problems such as poor overcurrent capability and poor mechanical connection strength, and achieve improved production efficiency and mechanical strength. , the effect of good overcurrent capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

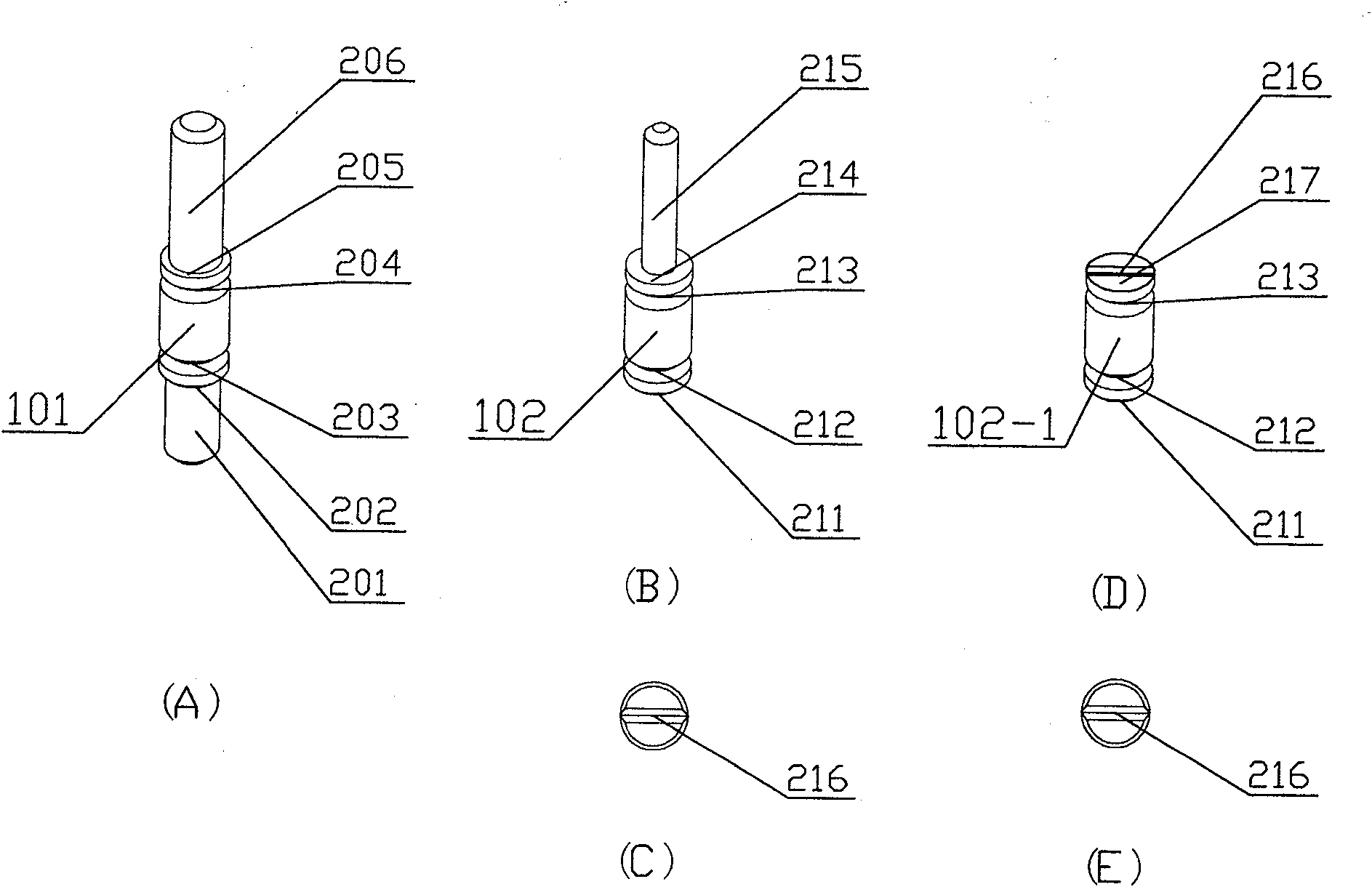

[0023] refer to image 3 (A), the perforated pin 101 has a first installation head 201 , a first step 202 , a V-shaped anti-tin groove 203 , a V-shaped anti-slip groove 204 , a second step 205 and a second installation head 206 . Mounting head 201 and mounting head 205 each have inverted feet to facilitate alignment and assembly. The length of mounting head 201 can be smaller than the thickness of the module power supply PCB to be suitable for SMT process production. refer to image 3 (B, C), an embodiment of the surface-mounted pin 102 , on which there is a first soldering surface 211 , a small V-shaped anti-tin groove 212 , a small V-shaped anti-slip groove 213 , a step 214 , and a mounting head 215 . refer to image 3 (D, E), another embodiment of the surface mount type pin 102, with image 3 (B) The embodiment is different in that the steps 214 and the mounting head 215 are replaced by the second soldering surface 217 to form another surface mount pin 102 - 1 . Both th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com