Device for cleaning and drying huge bearing through composited swing and spraying

A spray cleaning and bearing technology, applied in drying, drying solid materials, cleaning methods and appliances, etc., can solve the problems of complex structure of large-scale finished bearings, repeated use of cleaning fluid, low cleaning efficiency, etc., and save anti-rust oil , Improve the quality of anti-rust, reduce the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

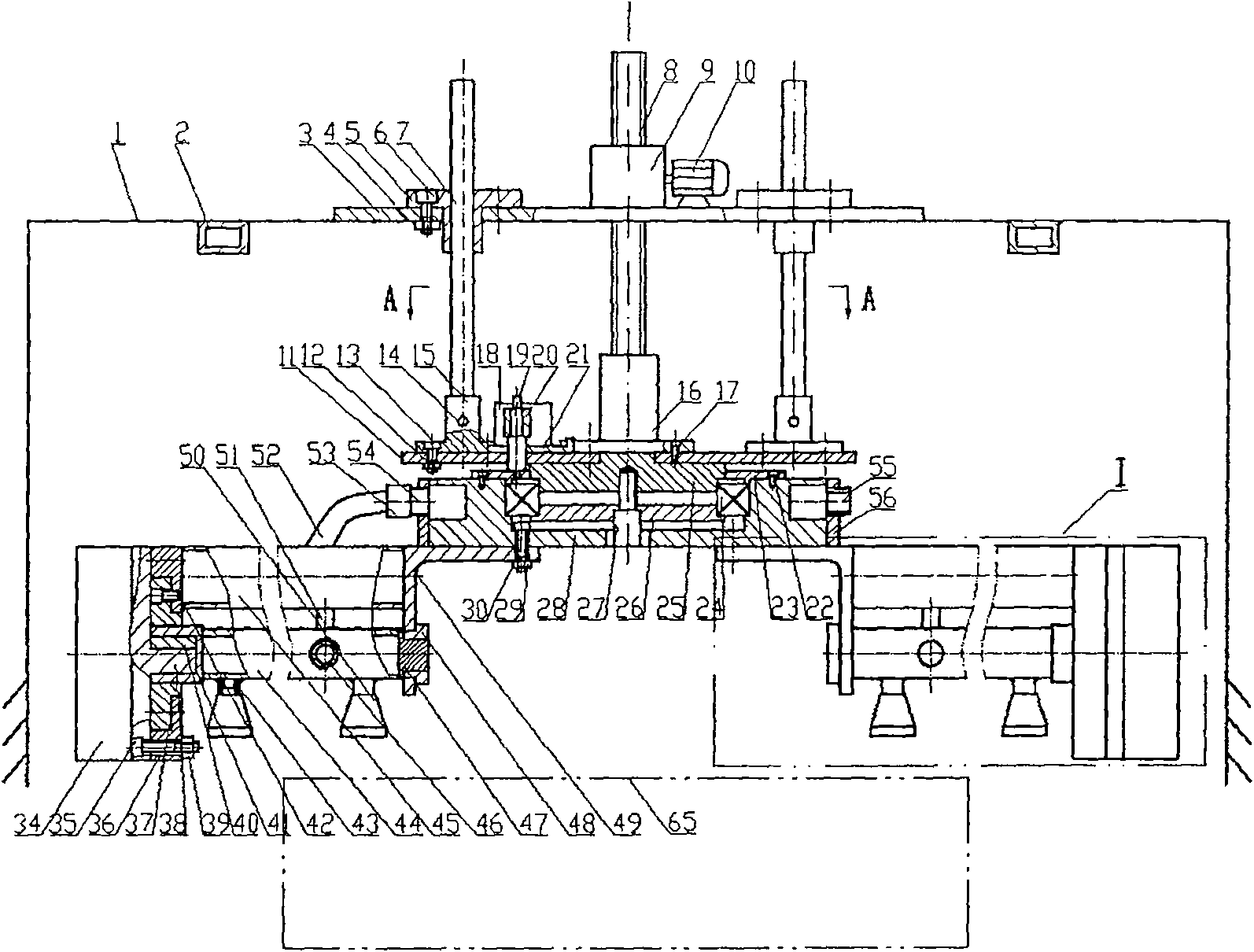

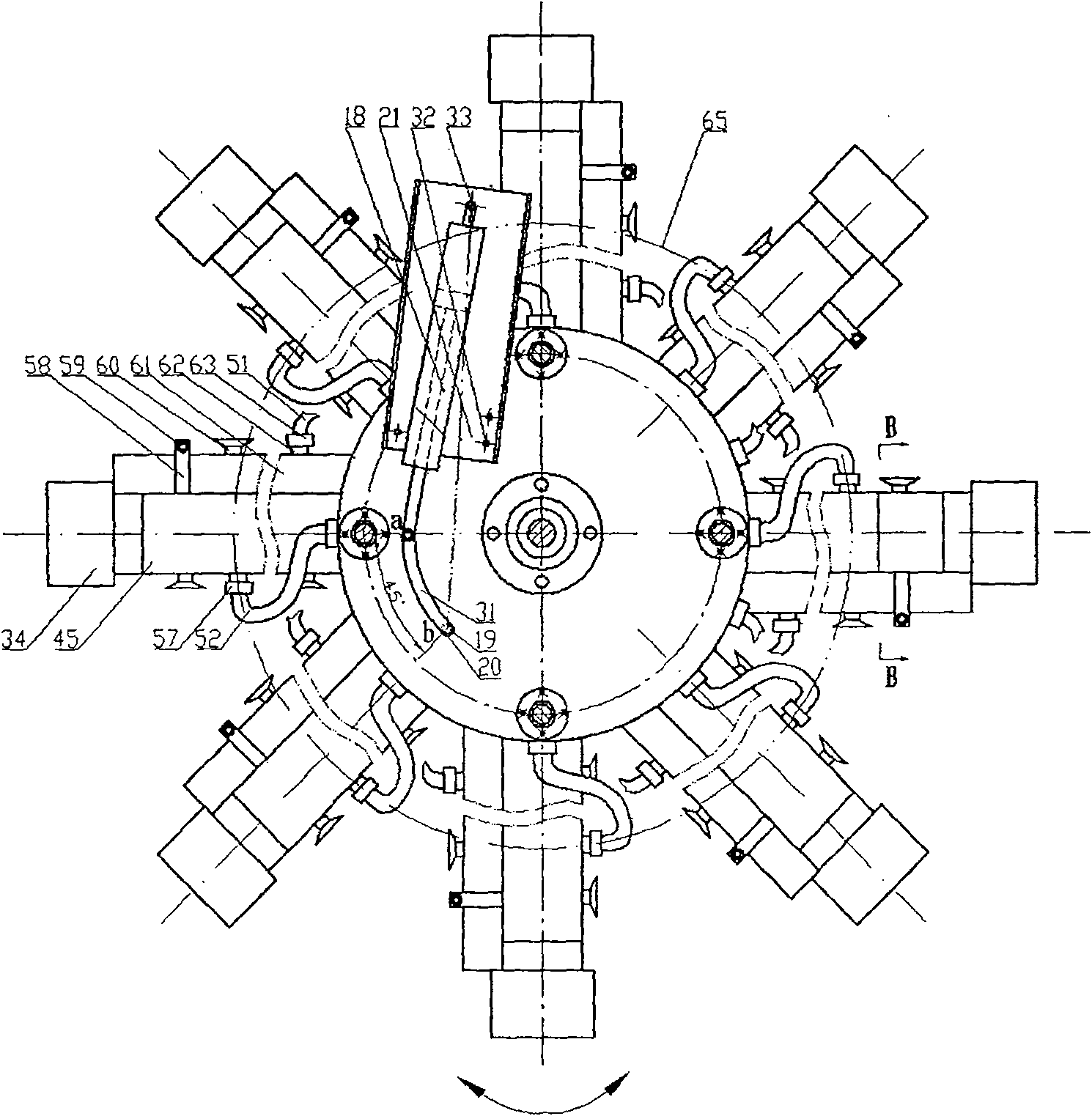

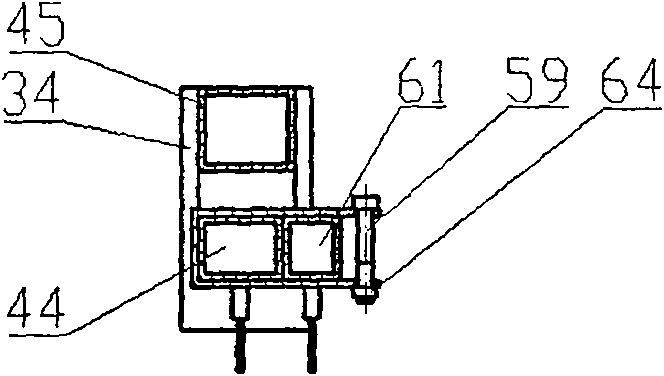

[0010] The specific implementation modes and examples of the present invention will be described in detail below in combination with the technical scheme and the accompanying drawings. as attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4As shown in the figure, the device for cleaning and drying large-scale bearings by compound swing spraying adopts a modular structure. In the example of the present invention, there are 4 guide posts 7 for lifting and guiding, and there are 8 shower heads 1 in groups, and the structures are identical. The whole cleaning device is composed of 4 parts, the lifting mechanism, the overall rotary swing mechanism in the horizontal plane, the independent drive rotary swing mechanism in the vertical plane, and the liquid / gas conveying circuit, and the operation is automatically controlled according to the cleaning process. At the beginning of cleaning, the cleaned bearings are automatically transported to the cleaning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com