Large-scale bearing completed products cleaning transmission equipment

A technology for transmission equipment and bearings, applied in the field of finished bearing cleaning and transmission equipment, can solve the problems of high labor intensity, rust-proof oil pollution, etc., and achieve the effect of reducing labor intensity, reducing the number of replacements, and improving the quality of rust prevention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

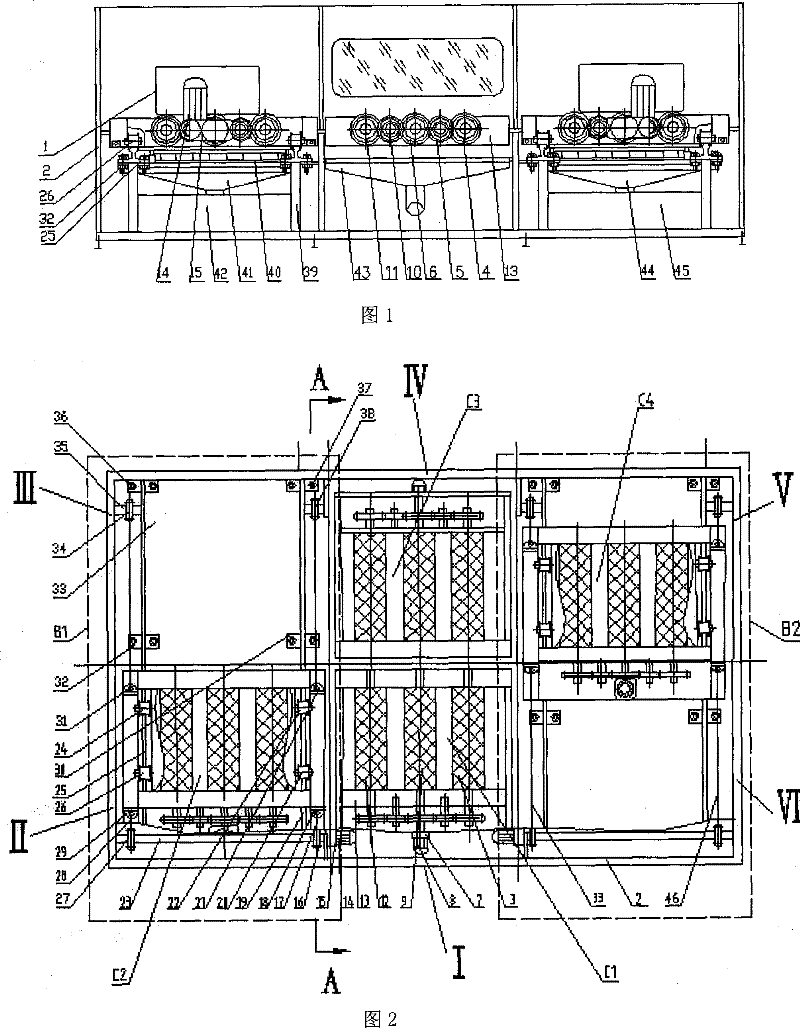

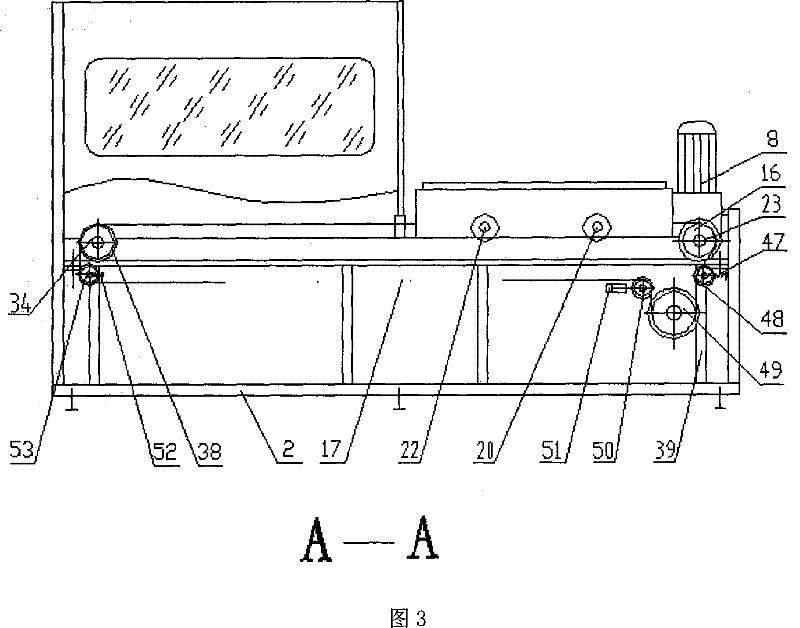

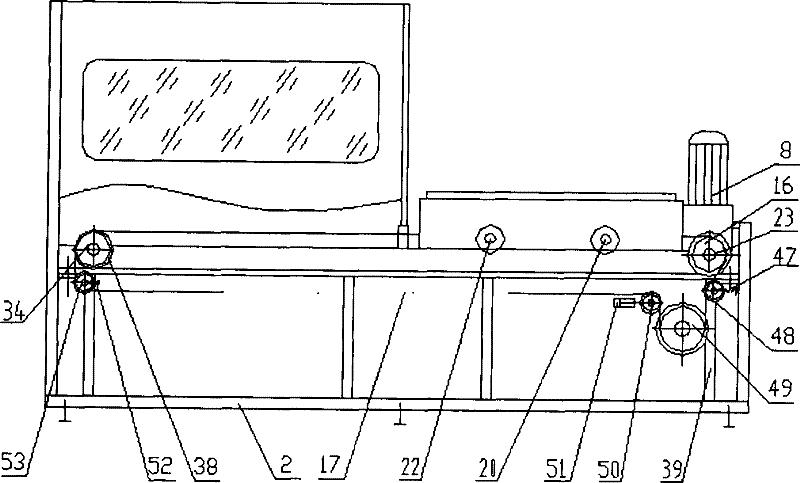

[0010] The specific embodiment of the present invention is described in detail in conjunction with the accompanying drawings. The equipment has a total of six stations. When designing and manufacturing, the process connection and transmission circular assembly line composed of 4 sets of horizontal transmission units and 2 sets of vertical transmission units, all stations are composed of The upper surface of the steel roller group is at the same level to ensure reliable operation of the cleaned bearing finished product 1 on the double-row six-station circular flow processing line, such as transmission, cleaning, drying control, and oiling; , the first transverse transfer unit C 1 , be fixedly installed on the loading station I, during transmission, the motor drives the gear to rotate, drives the transmission steel roller to rotate, and the rotation of the transmission steel roller completes the horizontal transmission of the bearing finished product from the feeding station to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com