Equipment and process for producing PPR pipe material by using novel core and vacuum chilling cabin

A technology of collecting cold box and vacuum, which is applied in the field of forming or connecting device for pipe plastics, can solve the problems of large electricity consumption of antibacterial PPR pipes, difficult to control the surface finish of mechanical properties of products, etc., to save electricity consumption and defective rate. Reduced, space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiments of the present invention are described below with reference to the drawings.

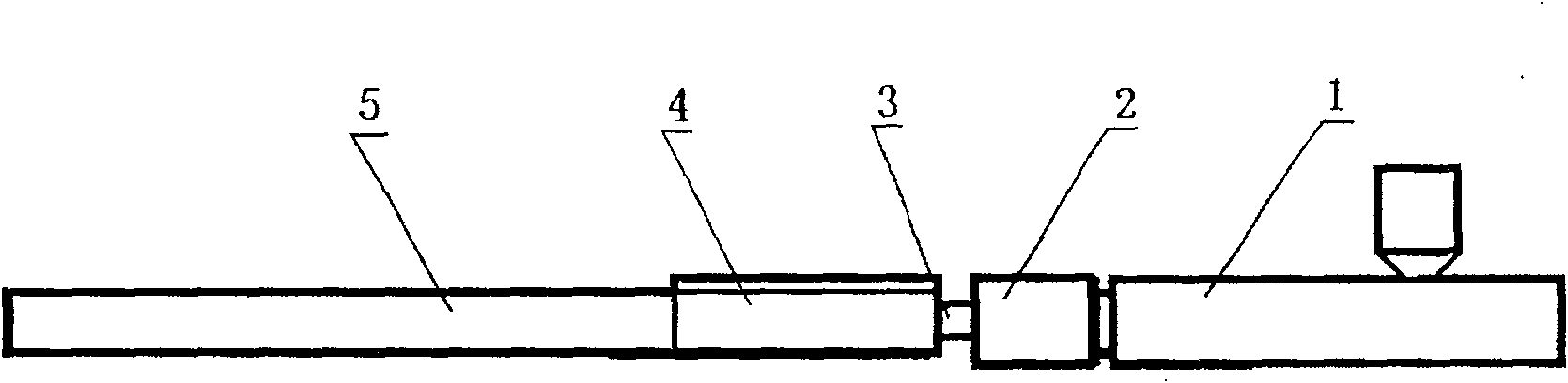

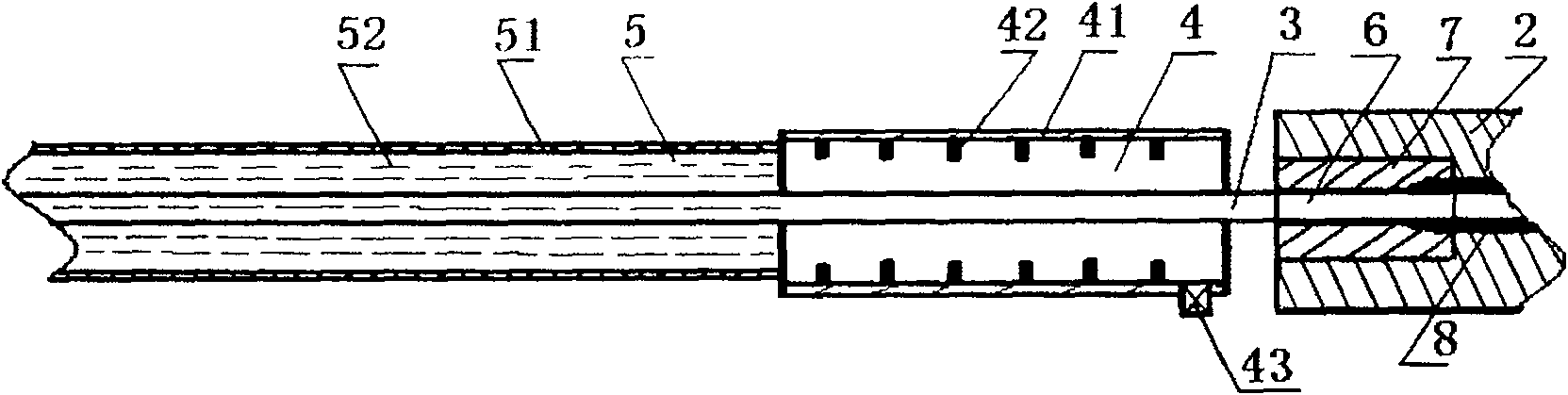

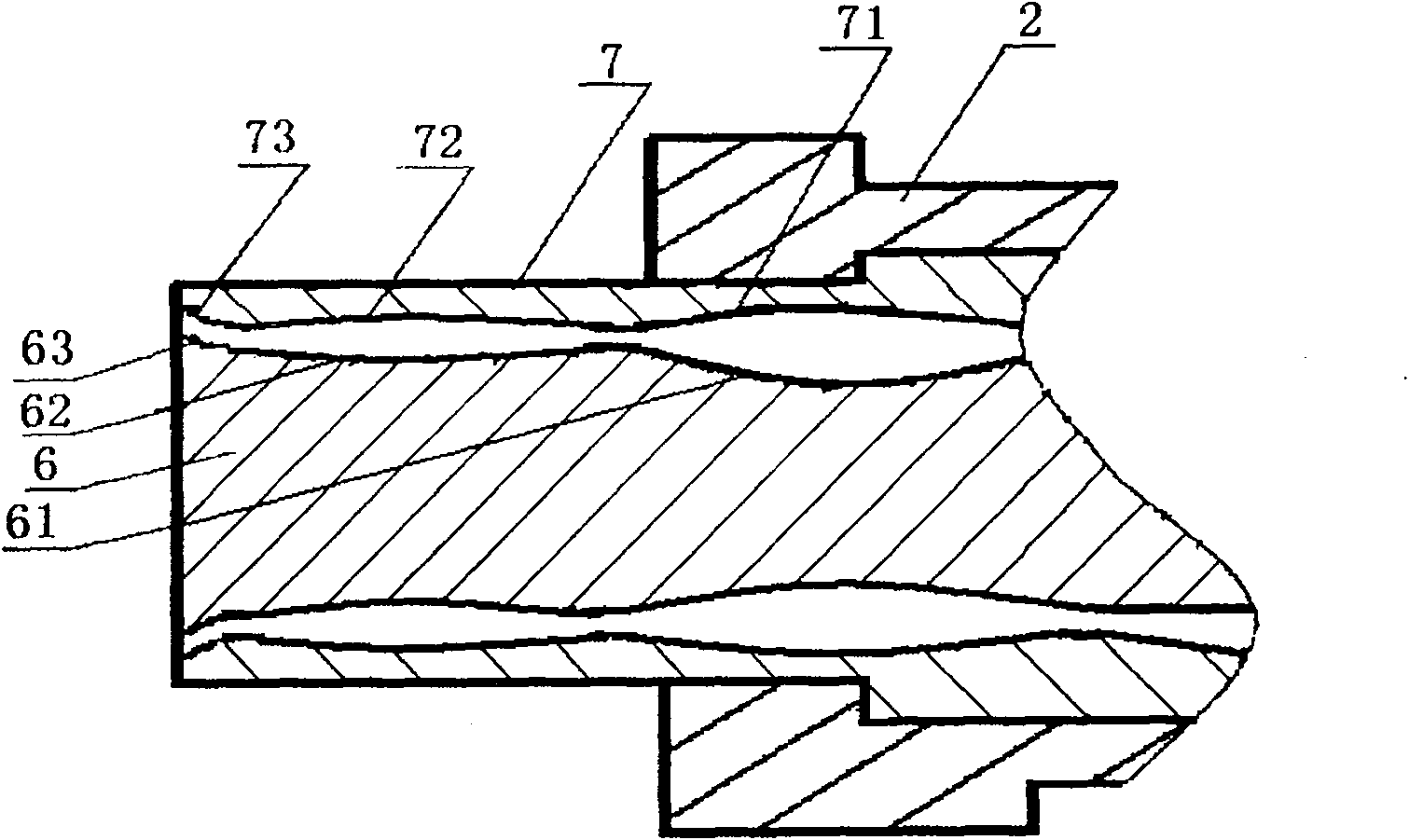

[0014] Such as figure 1 Shown is the overall principle diagram of the invention, figure 2 It is a cross-sectional view of the core mold section, vacuum condenser and water tank of the present invention. It can be seen from the figure that the present invention includes an extruder 1, a die 2. The improvement lies in that the die 2 passes the extruded pipe 3 through After the vacuum condenser 4 is sprayed and cooled, it is immersed and cooled in the cooling water 52 entering the water tank 5, and the finished product is finished after cooling.

[0015] In the present invention, the vacuum cold gathering box 4 is composed of 15-40 nozzles 42 and a vacuum pump 43 installed on the box body 41. The length of the vacuum cold gathering box 4 is 60-80 cm, and the number of nozzles 42 is the largest. Good for 20-30;

[0016] In the present invention, the water tank 5 is composed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com