Protein forage and preparing method thereof

A protein feed, protease technology, applied in the field of microbial engineering, can solve the problems of affecting safety, easy to produce salmonella, anti-nutritional factors and toxicity problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

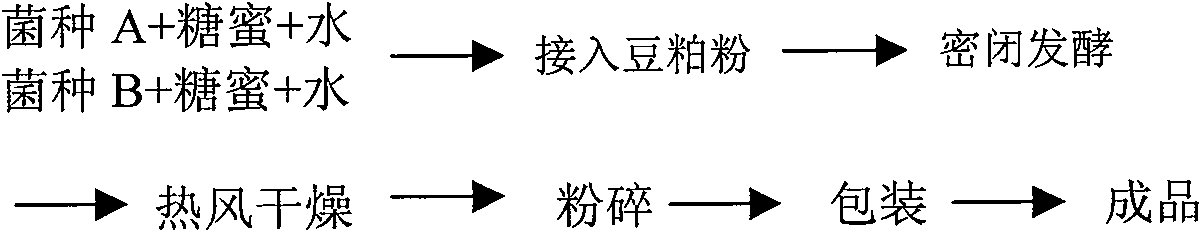

Method used

Image

Examples

Embodiment 1

[0100] 1) Activate Bacillus subtilis (CICC10265) at 28°C, culture in liquid, culture in solid, and dry to obtain 6 kg of bacterial powder;

[0101] 2) Activate Lactobacillus plantarum (CICC6001) at 30°C, culture in liquid, culture in solid, and dry to obtain 5.5 kg of bacterial powder;

[0102] 3) Add 80 kg of molasses to 100 kg of water, heat and dissolve at 60°C, cool the obtained solution to 30°C, add the bacteria powder in 1) and 2), mix, activate, and mix with 2kg of protease (Proteinase), After mixing evenly, add 1.0 tons of soybean meal, solid-state fermentation for 2 days, and dry with hot air to obtain the final product.

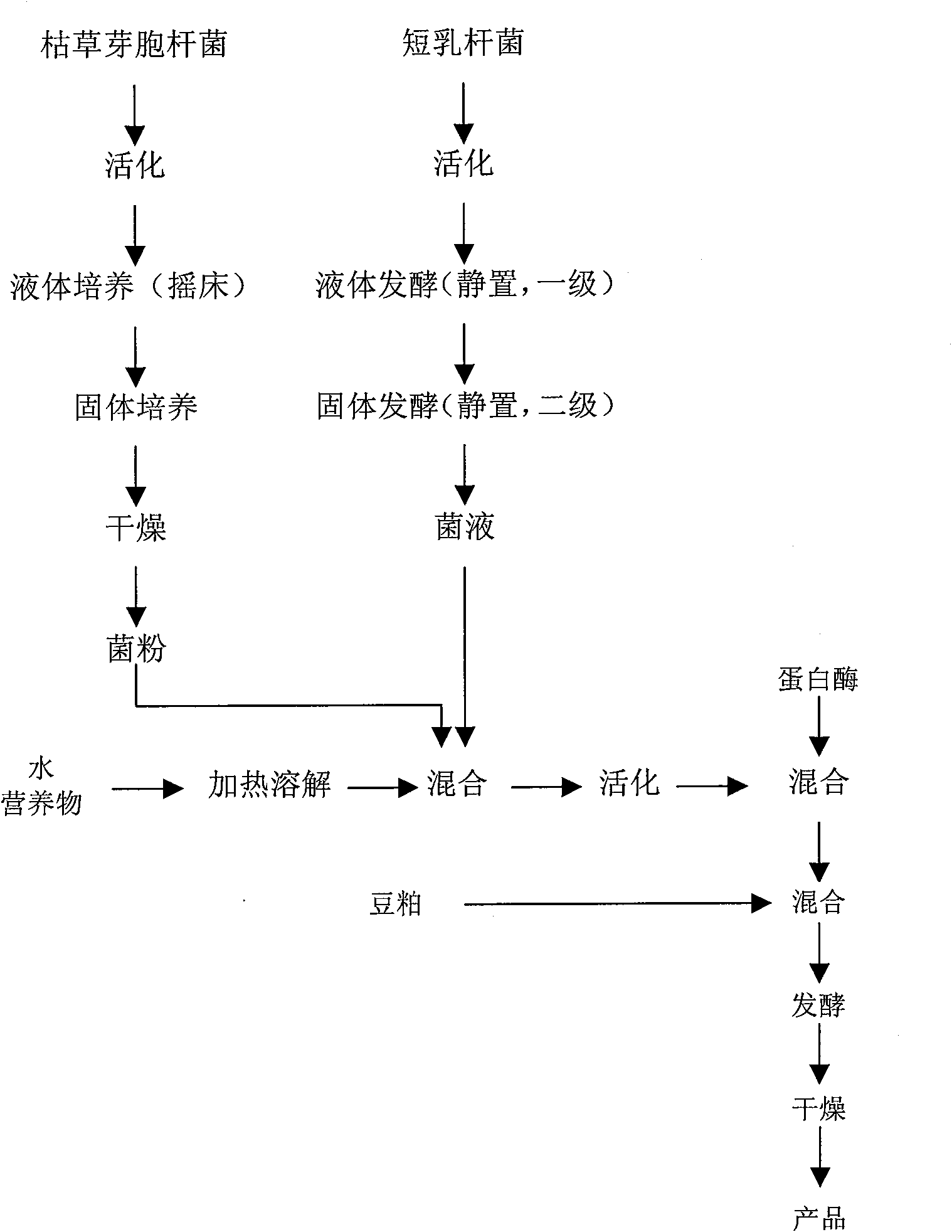

Embodiment 2

[0104] 1) Activate Bacillus subtilis (CICC10075) at 30°C, culture in liquid (shaking table), culture in solid, and dry to obtain 2 kg of bacterial powder;

[0105] 2) Activate Lactobacillus brevis (CICC6004) at 37°C, and obtain 10L of bacterial liquid after static fermentation;

[0106] 3) Add 20 kg of molasses to 100 kg of water, heat and dissolve at 60°C, cool the obtained solution to 30°C, add the bacterial powder and bacterial liquid in 1) and 2), mix, activate, and mix with protease (Proteinase) 3kg was mixed, and after mixing evenly, 1.0 tons of soybean meal was added, solid-state fermentation was carried out for 5 days, and the final product was obtained through hot air drying.

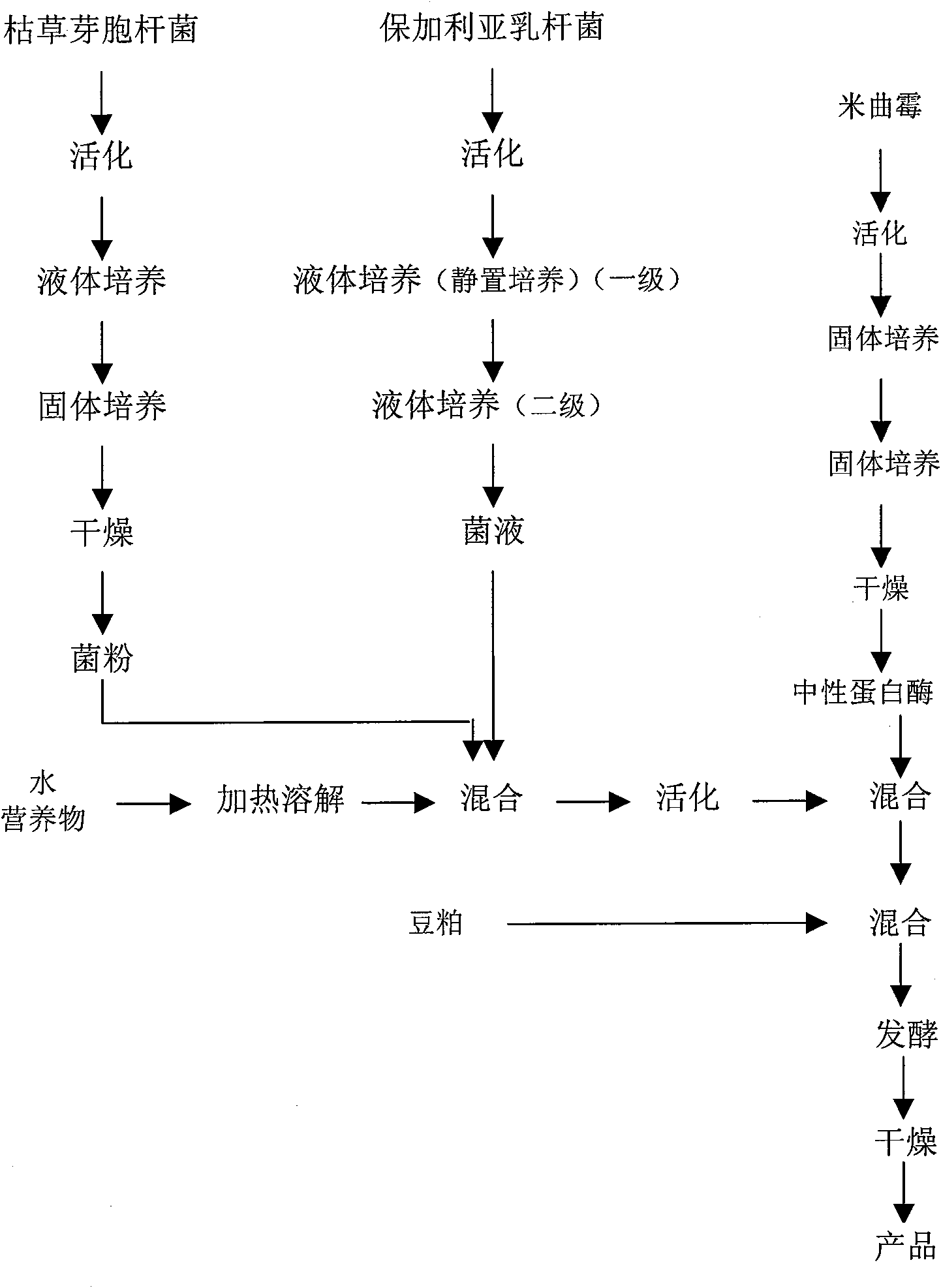

Embodiment 3

[0108] 1) Activate Bacillus megaterium (ACCC10008) at 28°C, culture in liquid, culture in solid, and dry to obtain 10 kg of bacterial powder;

[0109] 2) Activate Saccharomyces cerevisiae (CICC1856) at 28°C, and obtain 7kg of bacterial powder through liquid culture, solid culture and drying;

[0110] 3) Lactobacillus bulgaricus (CICC6045), Streptococcus lactis (CICC60036), and Lactobacillus plantarum (CICC6001) were respectively activated at 30°C for primary liquid culture, and then mixed for secondary culture to obtain 16 kg of bacterial liquid;

[0111] 4) Add 150 kg of molasses to 100 kg of water, heat and dissolve at 70°C, cool the obtained solution to 30°C, add the bacterial powder in 1), 2) and the bacterial liquid in 3), mix and activate, add 1.0 tons of soybean meal, solid-state fermentation for 4 days, and drying with hot air to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com