Quick dispensing device for lens module group assembling

A dispensing device and lens module technology, applied in installation, optics, instruments, etc., can solve the problems of increased probability of failure, loss of optical filters, time-consuming, etc., to enhance adhesion, reduce the probability of failure, and ensure The effect of dispensing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, an embodiment will be used to describe a glue dispensing device for lens module assembly.

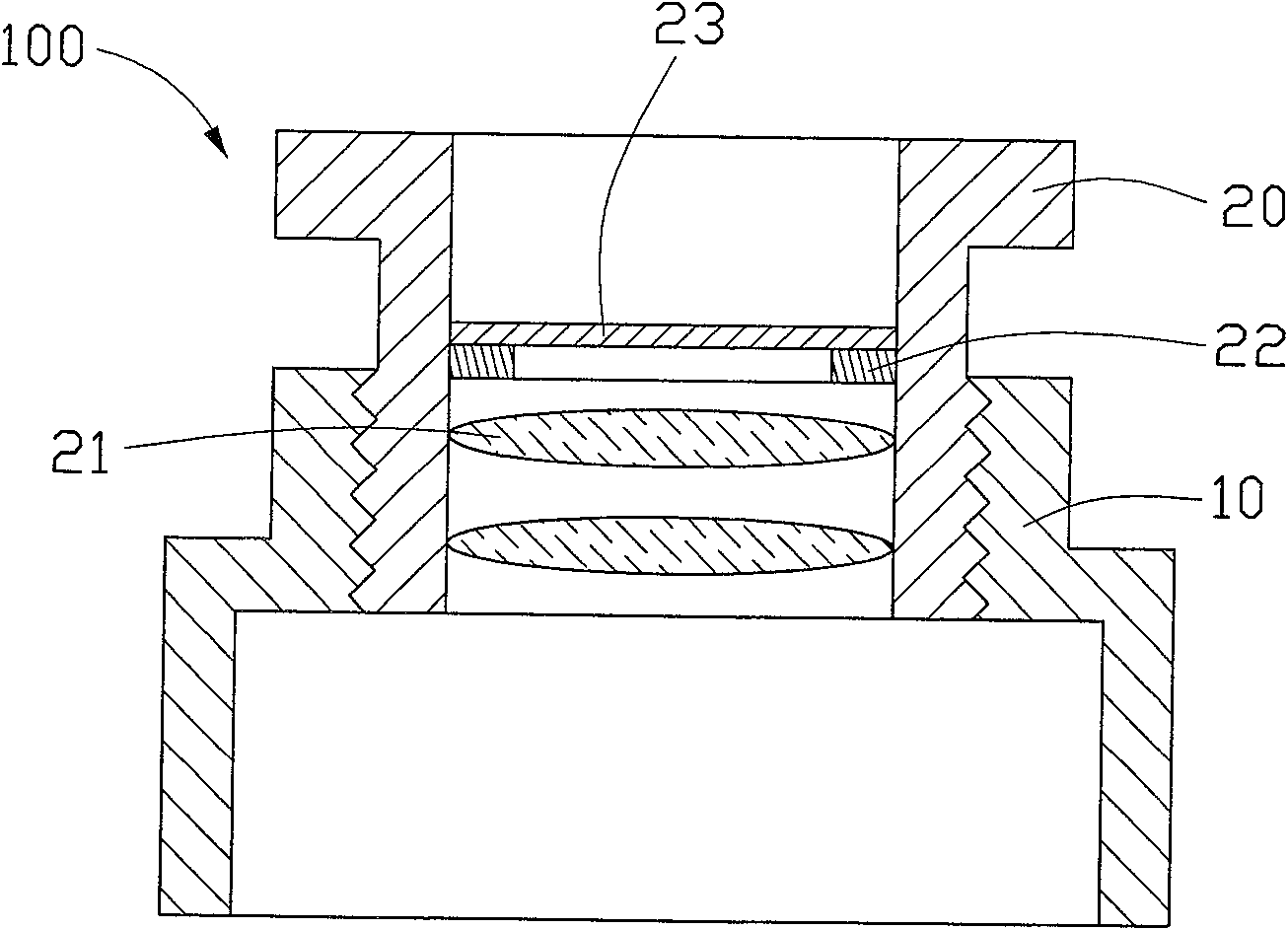

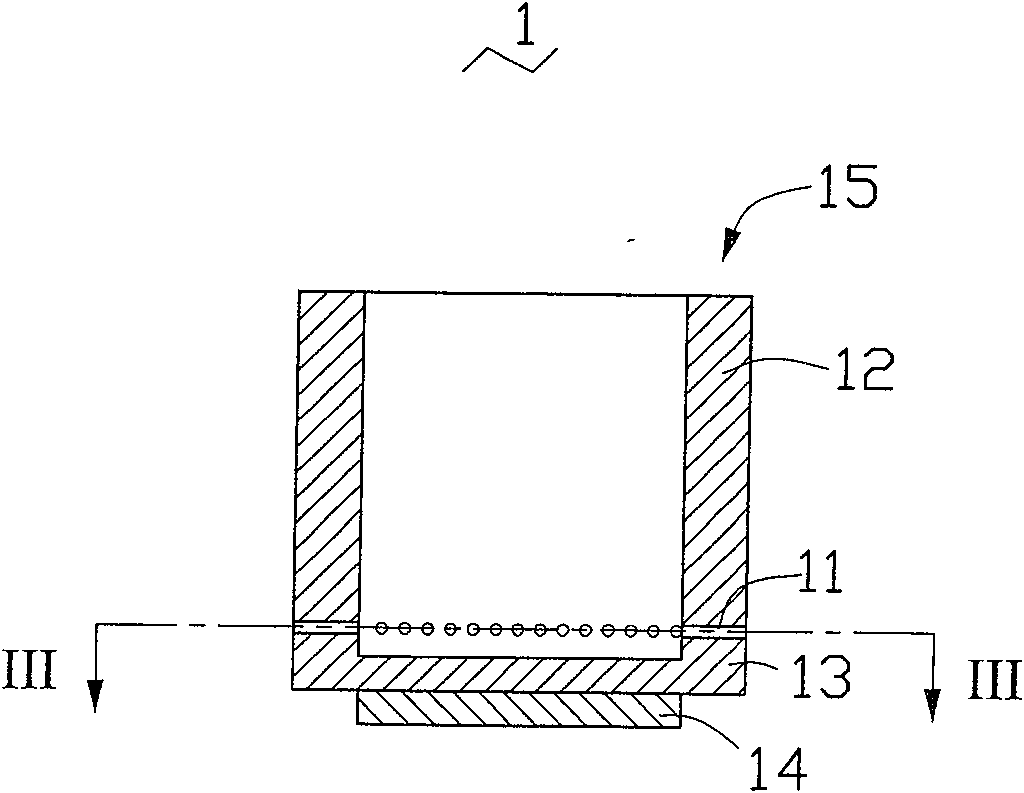

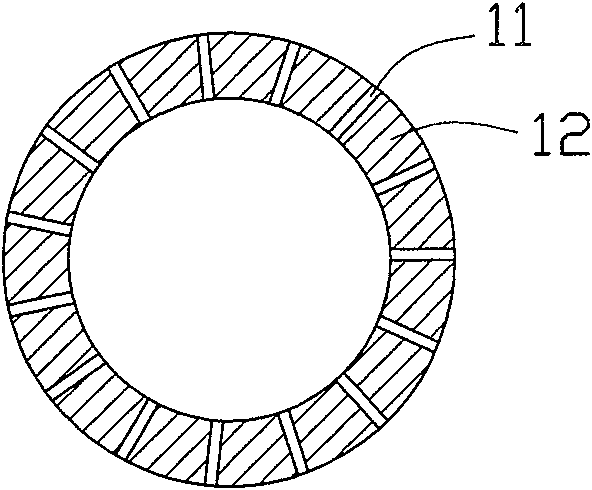

[0023] See figure 2 with image 3 , Is the glue dispensing device 1 provided by the first embodiment of the present invention. The glue dispensing device 1 for assembling a lens module includes a glue storage chamber 15 with an open end. The glue storage chamber 15 has at least one glue outlet 11, a side wall 12 and a bottom 13. The glue dispensing device 1 further includes at least one positioning portion 14, the at least one glue outlet 11 is arranged at a position of the side wall 12 close to the bottom 13, and the positioning portion 14 is located on the outer surface of the bottom 13.

[0024] The material of the dispensing device 1 can be stainless steel or polytetrafluoroethylene.

[0025] The glue storage chamber 15 can form a straight cylindrical structure or other structures, such as Figure 4 As shown in the cross-sectional view of the glue storage chamber 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com