A method for the solid state polymerization of polyethylene terephthalate

A solid-phase polymerization, turbine technology, applied in chemical instruments and methods, mixers, mixers with rotary stirring devices, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

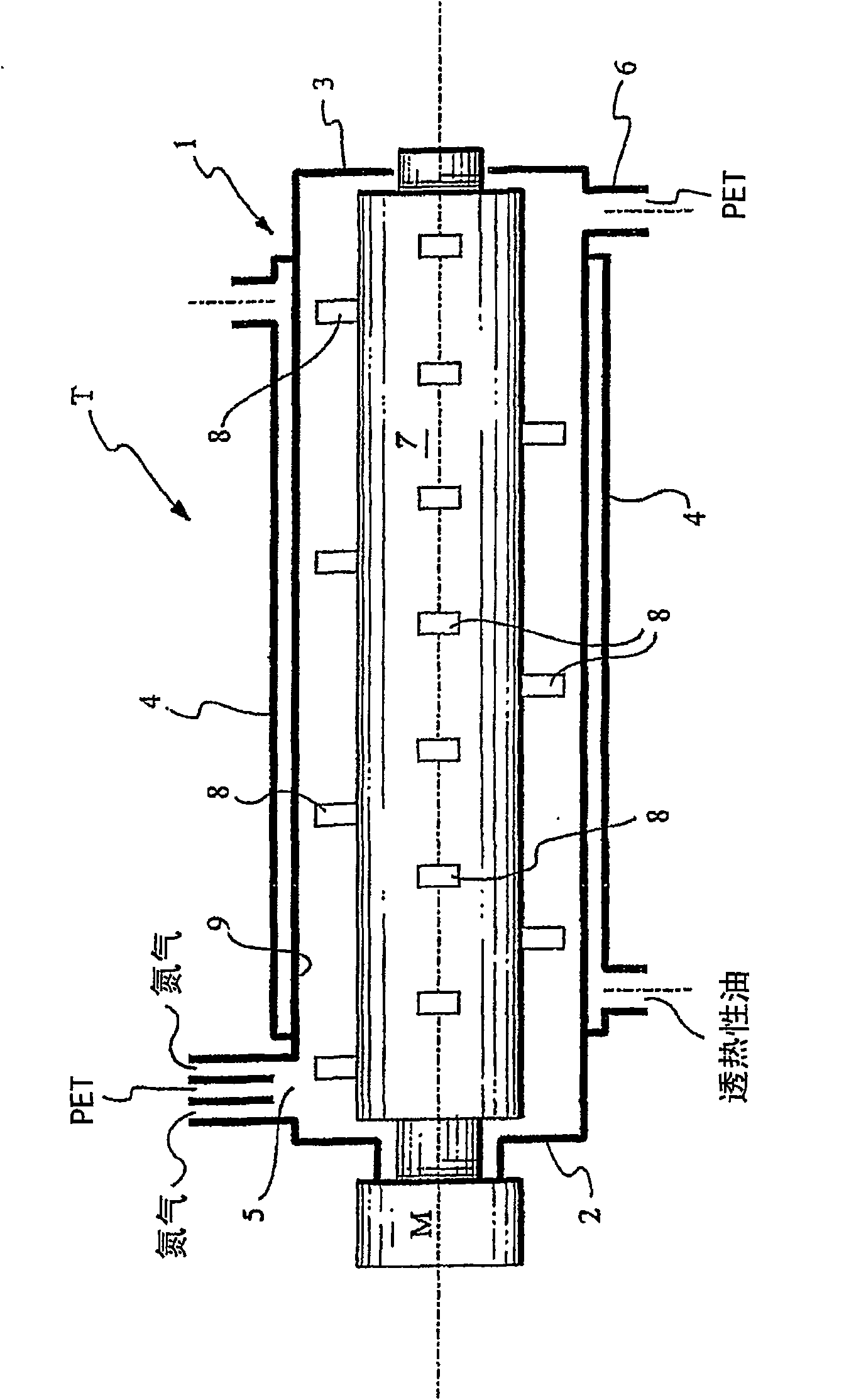

[0027] Referring to the drawings, the apparatus for solid-phase polymerization of PET includes a turbo heater T.

[0028] A turbo heater T (manufactured for example by the company VOMM Impianti e Processi of Rozzano (I-Milano)) essentially consists of a cylindrical tubular body 1 closed at its opposite ends by end plates 2, 3 and equipped with coaxial A heating jacket 4 through which a fluid such as thermally transparent oil will flow.

[0029] The tubular body 1 has an inlet 5 for flake or powdered PET material and an outlet 6 for product that has been subjected to solid state polymerization.

[0030] In the tubular body 1, a bladed rotor 7 is rotatably supported. The blades 8 of the rotor are helically arranged and oriented so as to create a centrifugal action while advancing the processed product towards the outlet. The motor M rotates the rotor 7 at a speed of 200 to 1500 rpm, preferably at a speed of 400-600 rpm.

[0031] For possible technical reasons, it is clear tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com