New method of processing the E type bolt

A bolt, a new type of technology, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of auxiliary clamping and tool sharpening time, no reliable processing and positioning means, large demand for E-bolts, etc. , to achieve the effects of high positioning accuracy, convenient operation, high position tolerance and dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A novel method for processing E-bolts is characterized in that it comprises the following steps:

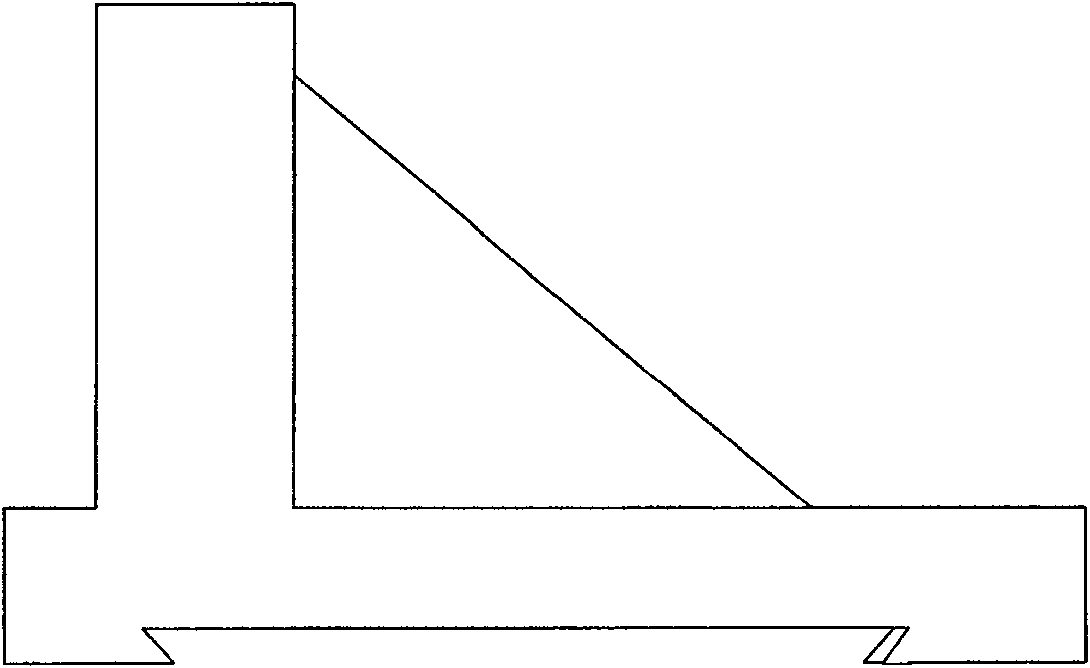

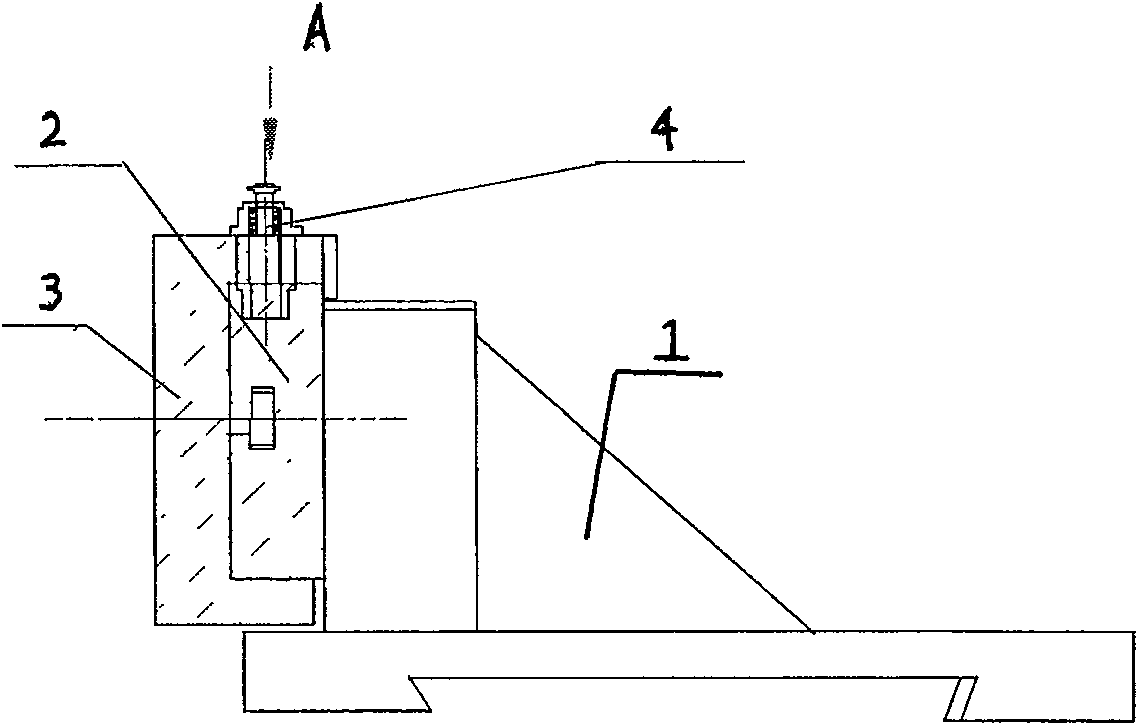

[0024] a. Processing and installation of special tires: first install the special processing tires on the middle carriage of the C6140 ordinary lathe, use inserts and bolts at the dovetail groove to fix the special processing tires and the middle carriage of the lathe together, and adjust Pad adjustment center height is consistent with the center height of the machine tool;

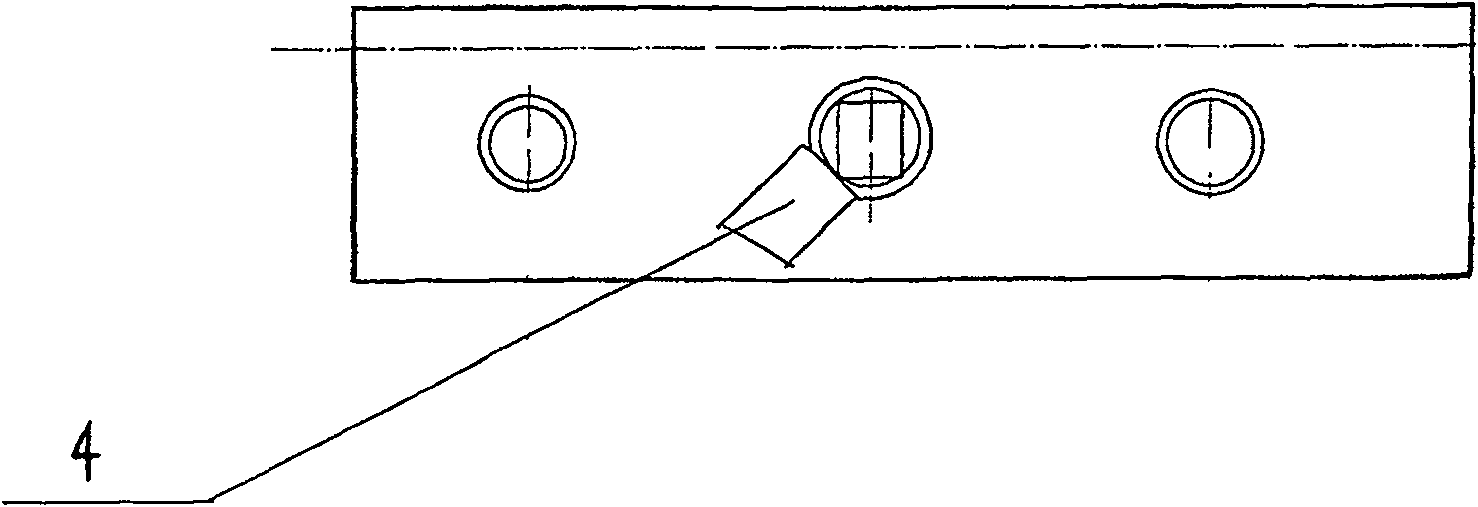

[0025] b. Turning outer circle and chamfering: first install the clamping tool of the sleeve type combined machine on the lathe chuck, place the E-bolt to be processed on the movable pressure plate of the special processing mold, lift the clamping pressure plate and pass it on the moving guide rail Use the swivel bolts to fix the E-bolts on the movable platen. Use a tool to tap and adjust the stud position of the E-bolts to make the center of the E-bolts match the center of the tool. The linear movem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com