Metal layer and insulation layer alignment error electricity testing structure in micro-electromechanical device process

A technology for alignment error and test structure, applied in microstructure technology, microstructure devices, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve problems such as alignment error extraction, achieve consistent measurement methods, and test The effect of simple method and simple test equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

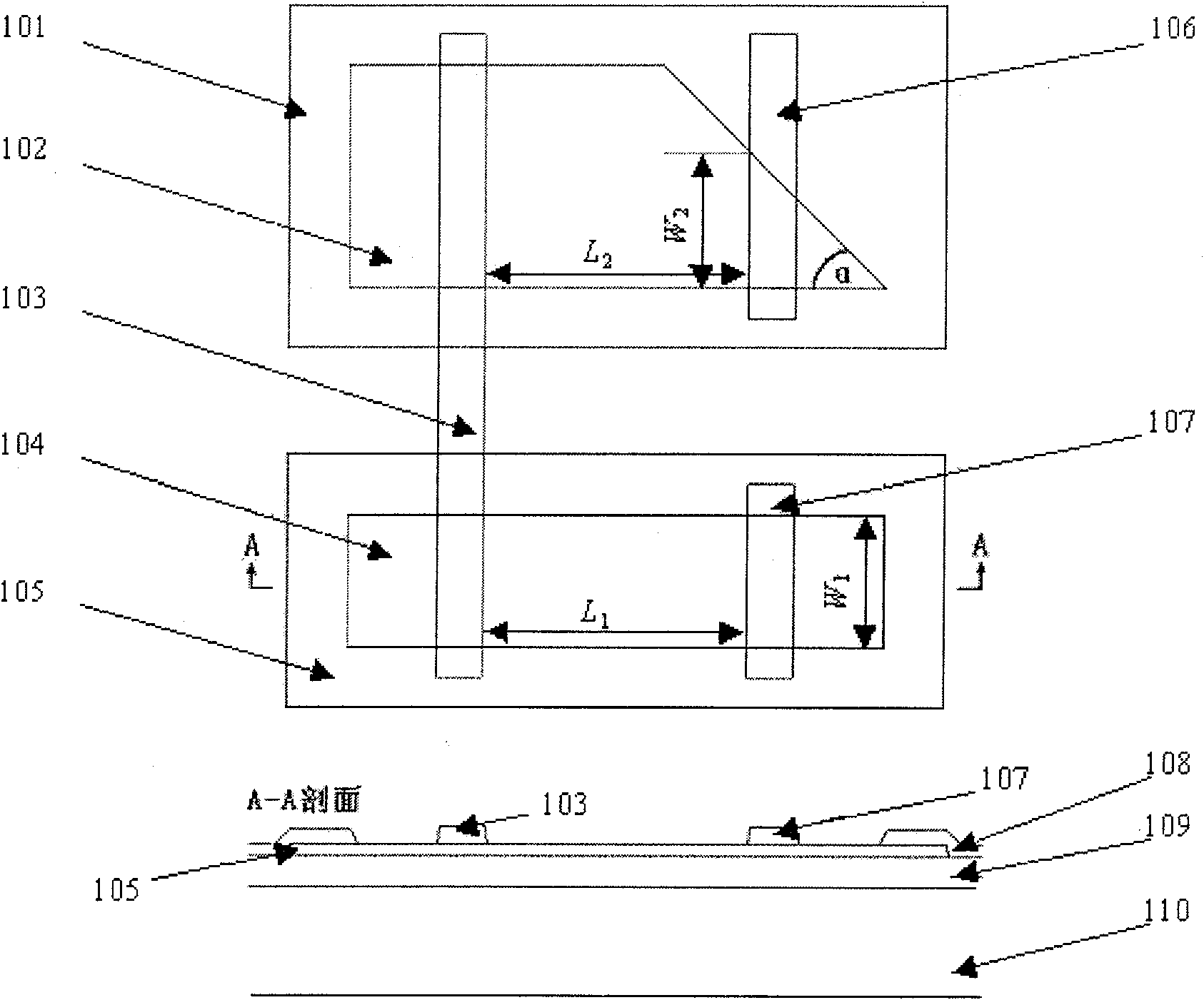

[0014] see figure 1 , the test structure graph of the error of the pattern of the metal layer to the pattern of the insulating layer is given, and the cross-sectional structure of the structure is also given in the figure. In the test structure, 101 and 105 are two rectangular semiconductor conductive materials, which provide resistance characteristics and are used to assist measurement. In the MEMS process, the material can be polysilicon, and their lower layer is an insulating layer material 109, usually silicon nitride. 102 is a trapezoidal hole structure, which is a hole opened on the insulating layer 108, so that another semiconductor conductive layer below is exposed, and presents a trapezoidal window pattern, and the slope angle of the trapezoidal hypotenuse is α. Similar to 102 , 104 is also a hole, which is a rectangular window pattern on an insulating layer 108 . 103, 106 and 107 are strip-shaped metal layer materials. 110 is a silicon substrate material.

[0015...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com