Different conductive layers alignment error electricity testing structure in micromotor system apparatus process

A technology of alignment error and test structure, applied in microstructure technology, microstructure devices, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve problems such as registration error extraction, achieve consistent measurement methods, test Simple method and simple test equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

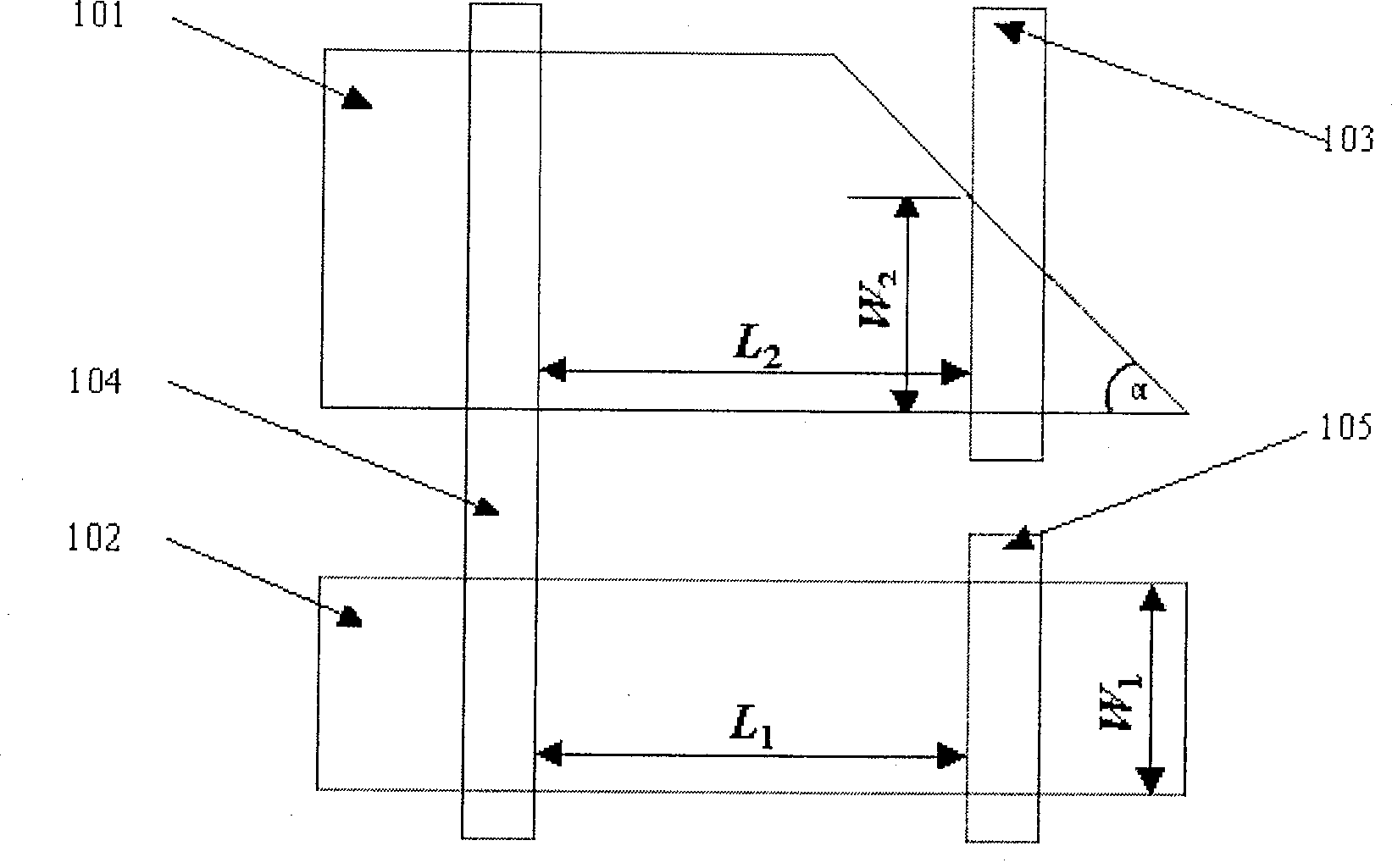

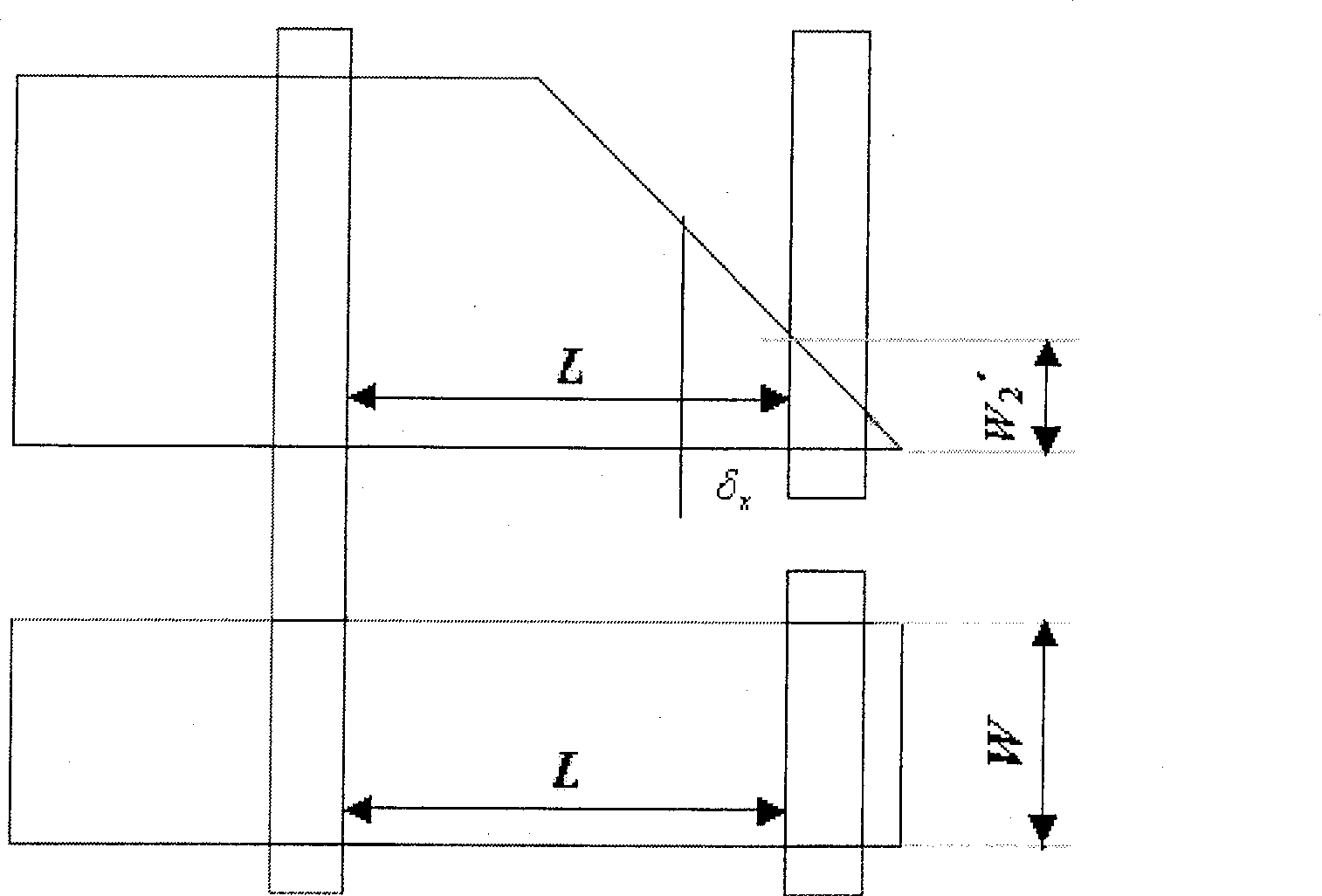

[0016] see figure 1 , in the test structure, 101 is a trapezoid, 102 is a rectangle, the material of these two patterns is a semiconductor material layer, which can be single crystal silicon, or polycrystalline silicon 1, polycrystalline silicon 2, they are all conductive due to doping Of course, there must also be resistivity. 103, 104, and 105 are strip-shaped metal layers. The metal strip and the semiconductor are contacted to form a connection, and the two metal strips 104, 103 (105) and the semiconductor between them jointly form a resistor with a connecting line. Its size is calculated by the following formula:

[0017] R = R S ( L W ) - - - ( 1 )

[0018] Among them, R S is the sheet resistance value of the semiconductor, L is the distance between two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com