Insulation layer thickness electric test structure in micro electro-mechanical systems device structure

A technology of insulating layer thickness and micro-electromechanical system, which is applied in the field of electricity and semiconductors, can solve the problems of slow measurement speed and achieve the effect of simple test equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

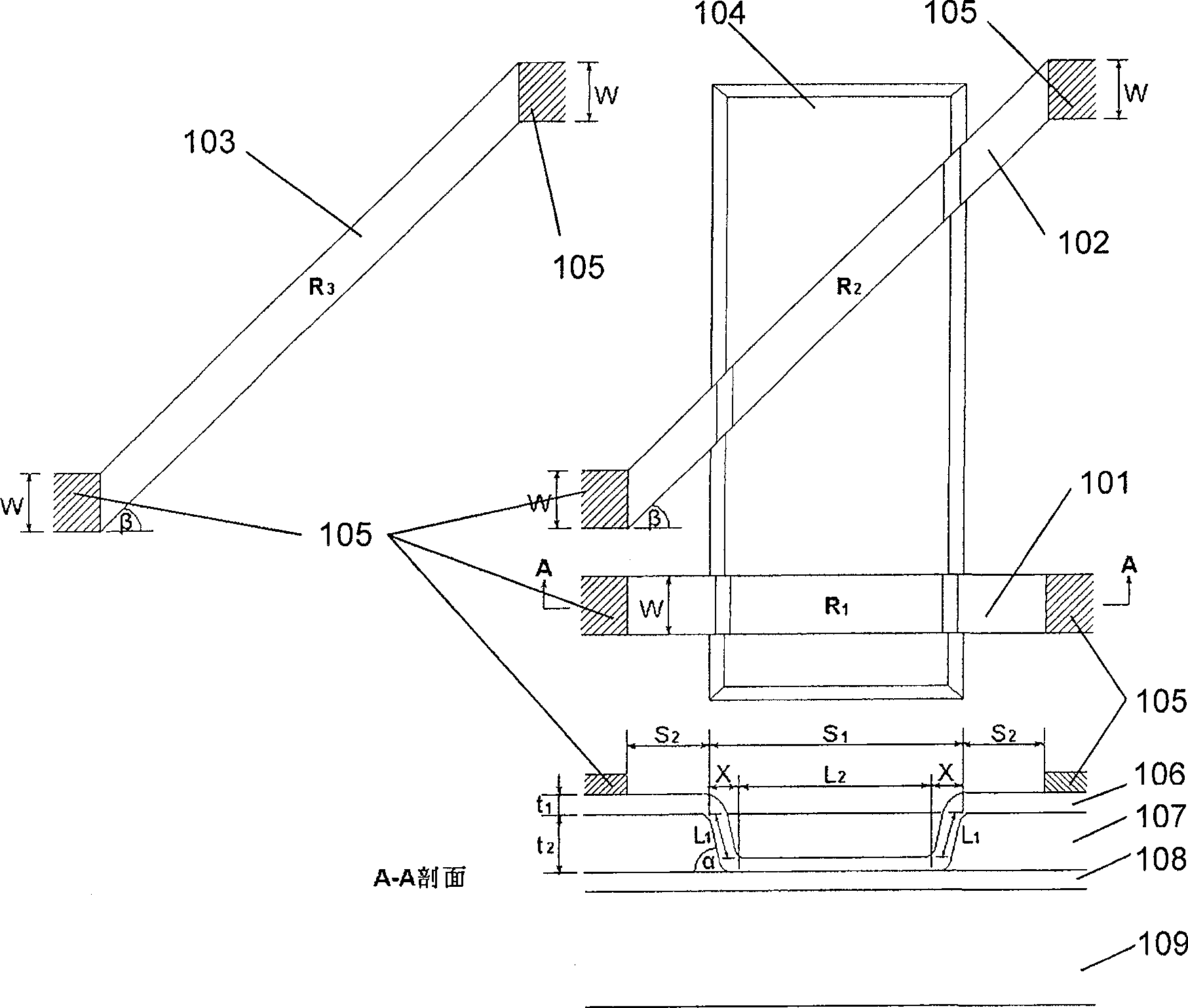

[0010] see figure 1 , in the test structure, 104 is the trench opened on the insulating layer 107, and the thickness of 107 is equal to t 2 , t 2 is the parameter ultimately required by the present invention. It can be seen from the section A-A that the insulating layer 108 whose depth reaches below, 107 and 108 are insulating layer materials with different properties, for example, 108 is silicon nitride, and 107 is silicon dioxide. The width design dimension of the groove 104 is S 1 , length to be able to lay down the polysilicon strip R 1 , R 2 And leave a certain length margin for the design size, such as figure 1 shown. The etched trench 104 usually has a certain angle, that is, the upper and lower widths are different, and the angle is represented by α.

[0011] 106 is polycrystalline silicon material, and its thickness is equal to t 1 . 101 is the polysilicon resistance bar R that polysilicon material 106 is made through photoetching, etching 1 , polysilicon st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com