Double surface drone based flow type tri-dimensional visual measurement splicing method

A technology of three-dimensional vision and double-sided targets, which is applied in measurement devices, radio wave measurement systems, and acquisition of 3D object measurement, to achieve high measurement efficiency, high precision, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The core idea of the present invention is: using two high-resolution digital cameras and a double-sided target to realize splicing of local measurement data of the visual sensor, the operation is simple and the measurement efficiency is high.

[0027] The present invention will be described in more detail below in conjunction with the accompanying drawings.

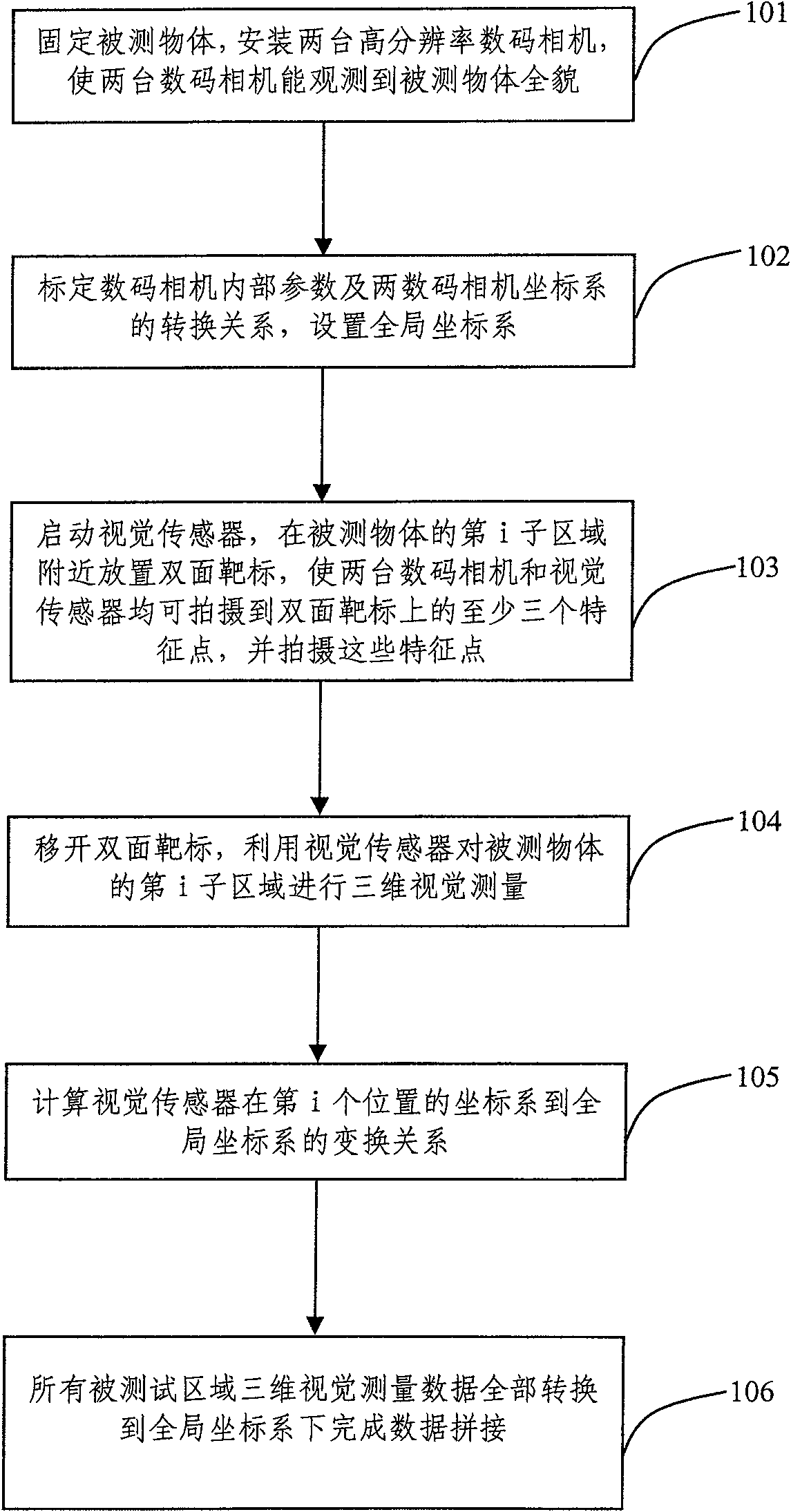

[0028] The three-dimensional measurement data mosaic method of the present invention comprises the following steps:

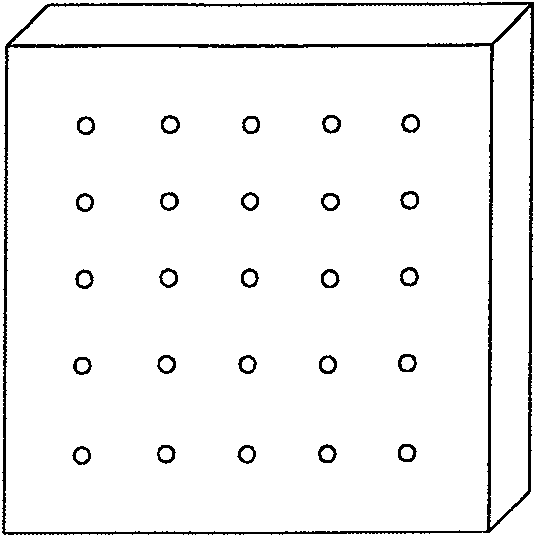

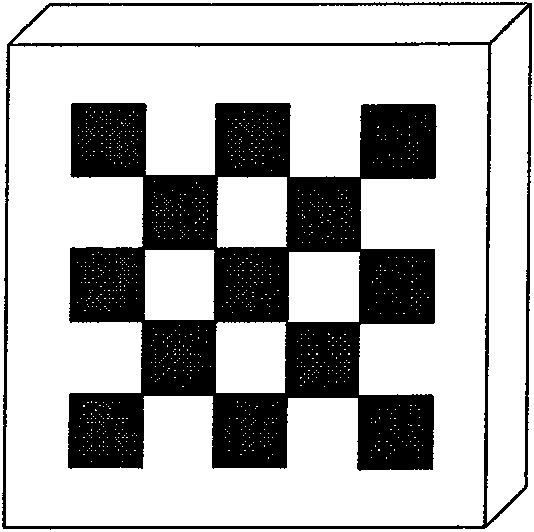

[0029] Step 101: fix the measured object, install two high-resolution digital cameras, so that the two digital cameras can observe the whole picture of the measured object. Here, it is not required that all the details of the measured object can be observed through two digital cameras, but when the visual sensor measures the three-dimensional data of the measured object, the two digital cameras can capture the double-sided target placed near the measured object At least three feature points on . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com