Method for producing ceramic tile with concavo-convex surface

A technology of concave-convex surface and production method, which is applied in the field of ceramic tiles, can solve problems such as the defects of the concave-convex surface of the green body, the different colors of the concave surface and the convex surface or flat surface of natural stone, and difficulty in meeting production requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

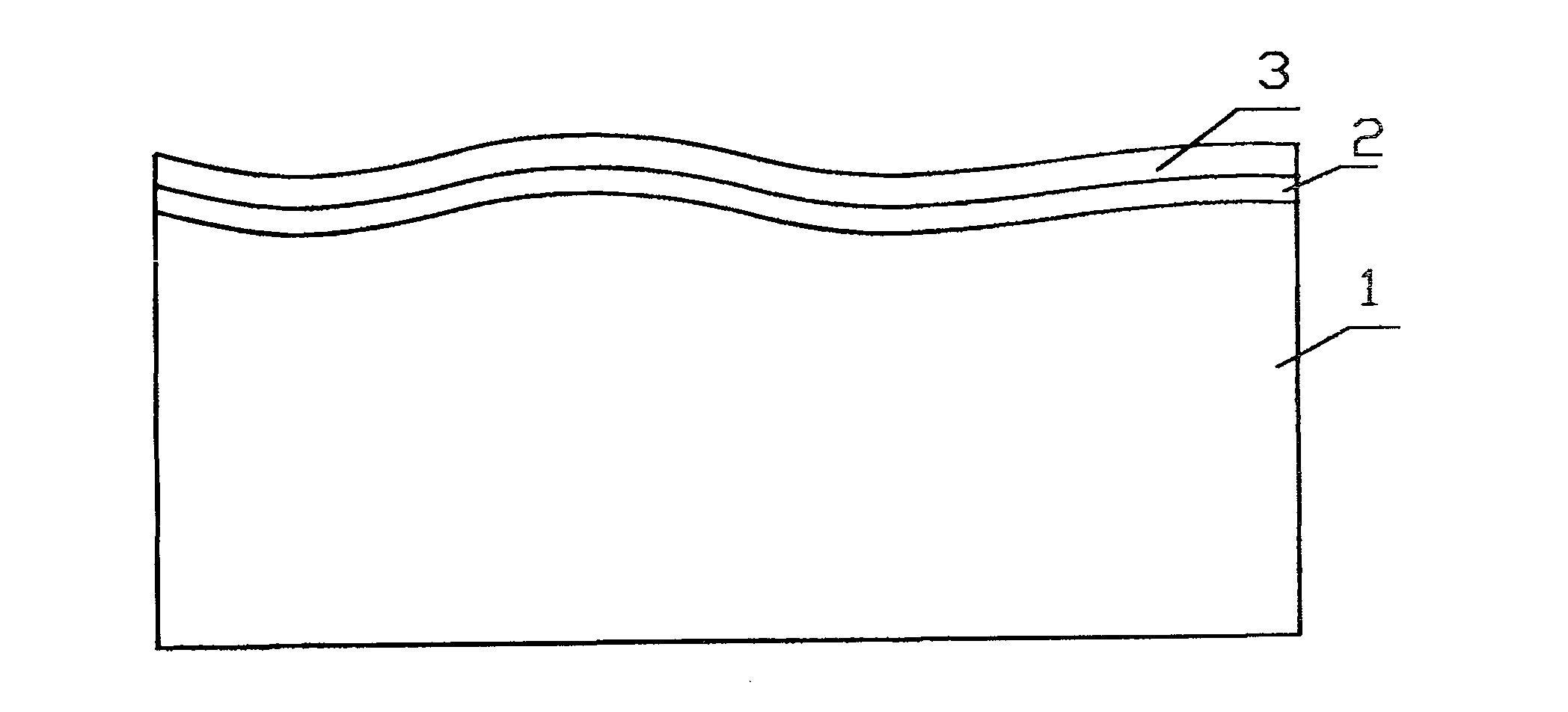

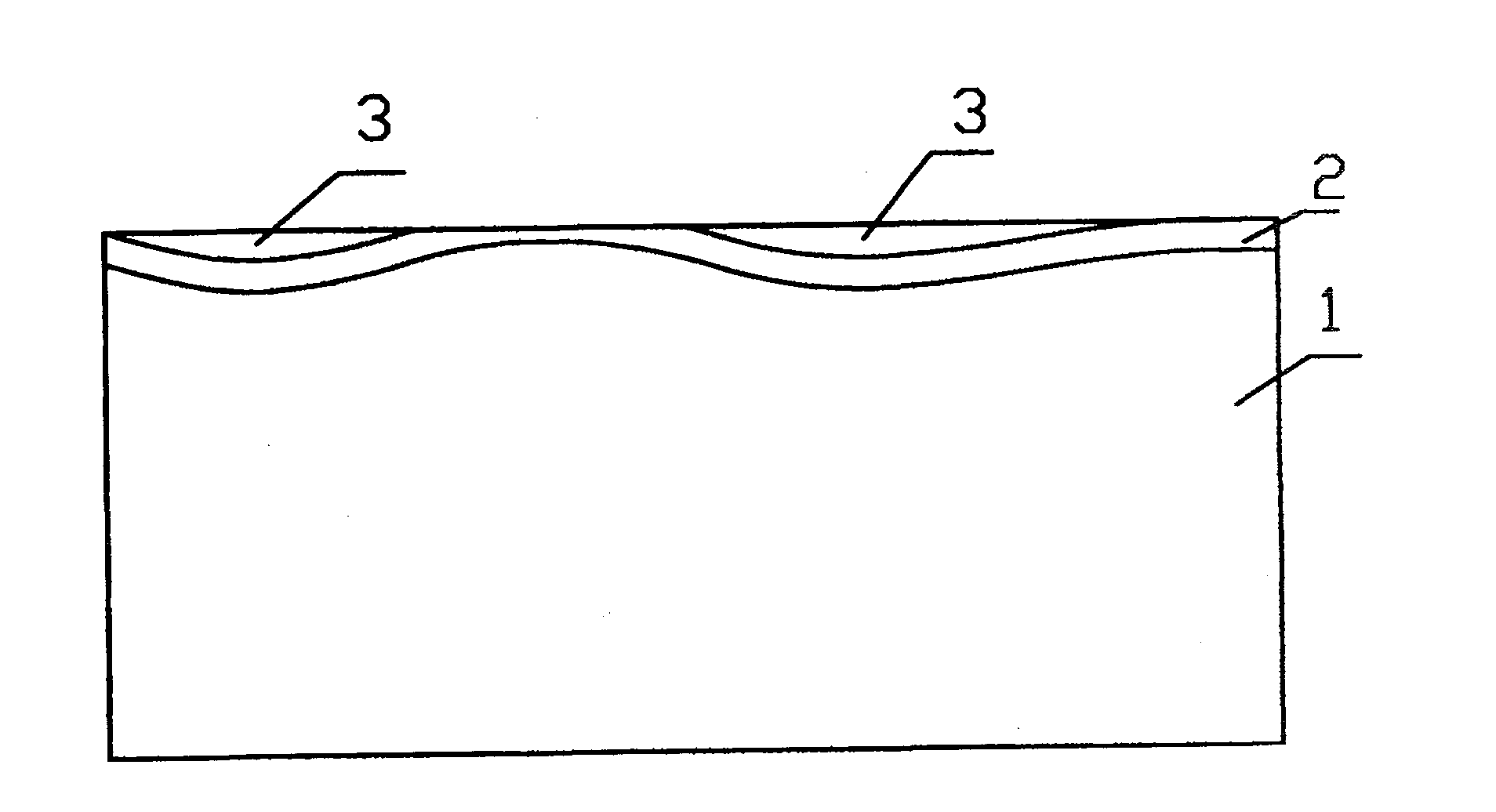

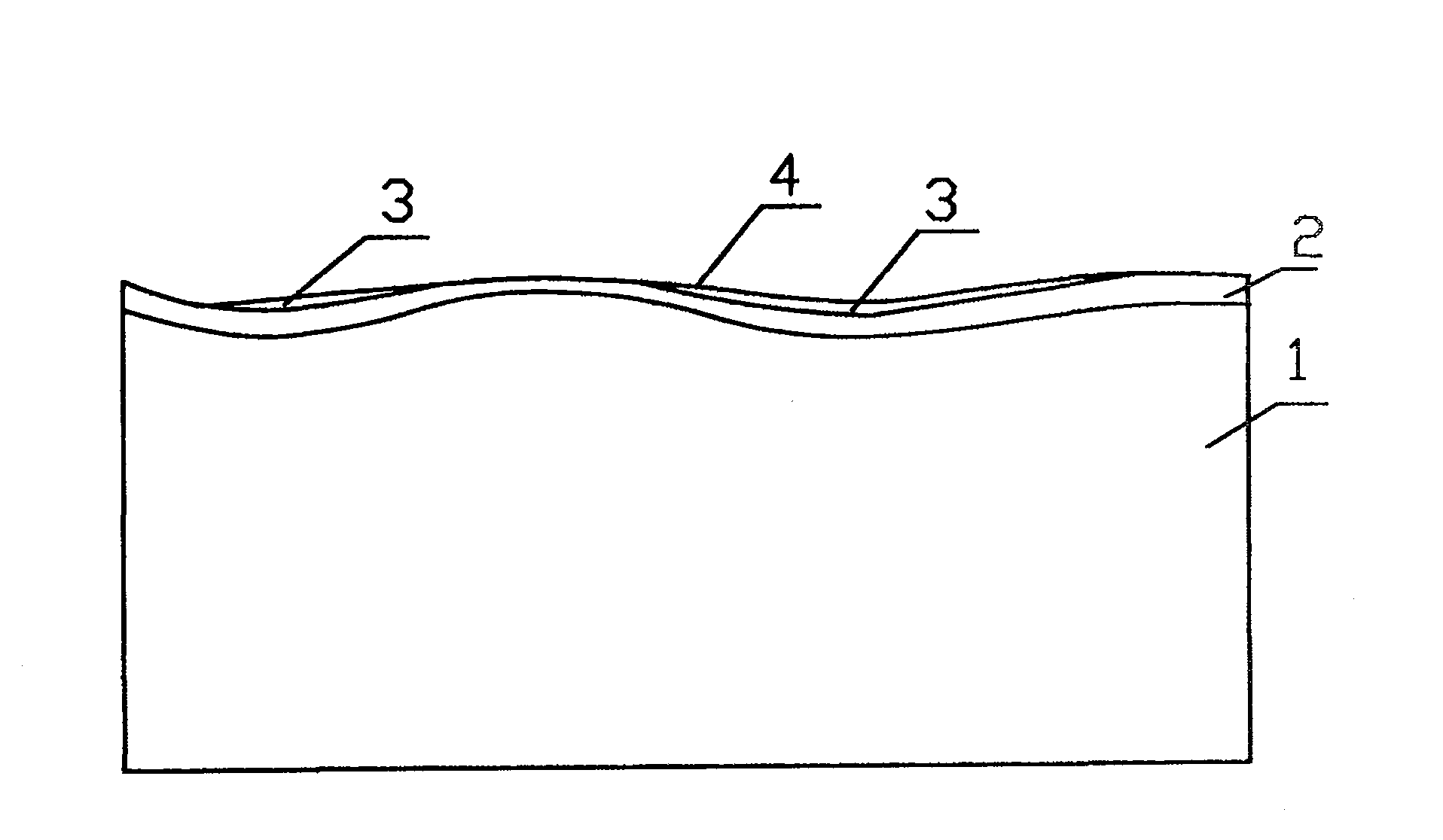

[0012] Firstly, the blank, glaze a, and glaze b are prepared. Glaze a and glaze b are glaze slurry prepared by mixing with water. Glaze a and glaze b have different colors or textures after being fired in a kiln. In the production line of ceramic printed tiles that generally have forming presses, dryers, glazing equipment, glaze grinding equipment, flat screen printing machines or roller printing machines, and kilns, the blanks are first pressed into ceramics with a concave-convex surface by a forming press. After the green body is dried by a dryer, the glazing equipment applies a certain thickness of glaze a on the surface of the green body for the first time with wet glazing, and then applies a certain thickness of glaze b for the second time. The glaze applied for the first time can be thinner For some, the glaze applied for the second time can be thicker. After the glaze surface dries up, use glaze grinding equipment to smooth the entire glaze surface, so that the concave s...

example 2

[0014] First prepare the blank and glaze a. Glaze a is the glaze slurry prepared by mixing water. The blank is formed into a blank with a concave-convex surface. A certain amount of glaze a is applied to the concave-convex surface of the blank by wet glazing, and the blank is dried. The glaze on the surface of the body, and then smooth the glaze surface, according to the unevenness of the surface of the body, the curvature of the concave-convex surface, and the size of the concave-convex surface, so that the concave area of the glaze surface that has not been ground is compared with the concave surface of the concave-convex surface of the body. The area can be reduced by more than 50% or more than 60% or more than 70% or more than 80% or more than 90% or more than 95%. According to the design requirements during printing, the entire glaze surface can be printed on flowers or more than 70% Flowers can be printed on the concave surface of the unground glaze surface or more than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com