Hydraulic drive device for working machine

A technology for working machines and driving devices, applied in mechanical equipment, machines/engines, engine working fluids, etc., can solve problems such as energy consumption, poor fuel consumption rate, inability to obtain pump absorption power, etc., to reduce fuel costs, eliminate The effect of fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

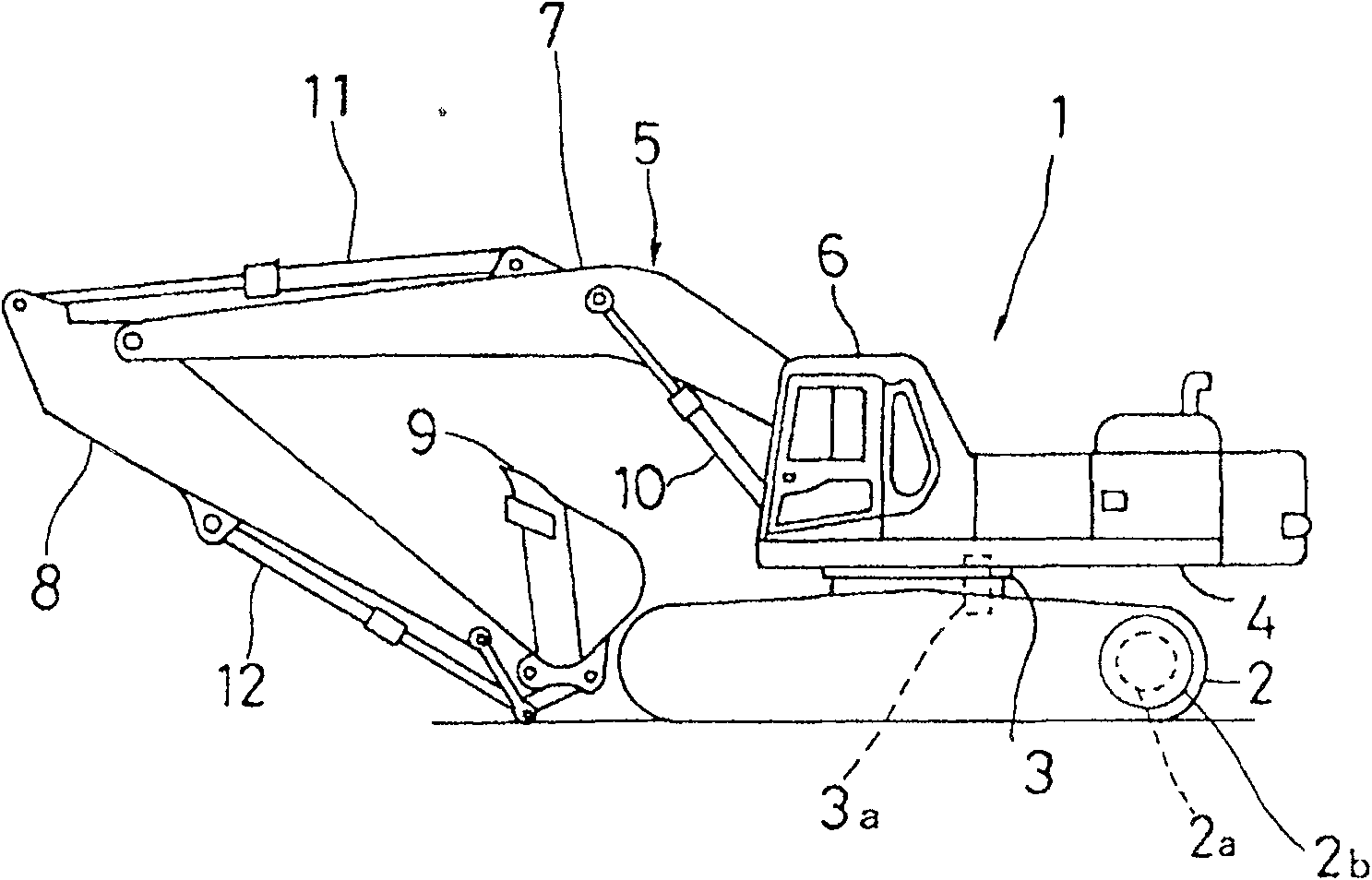

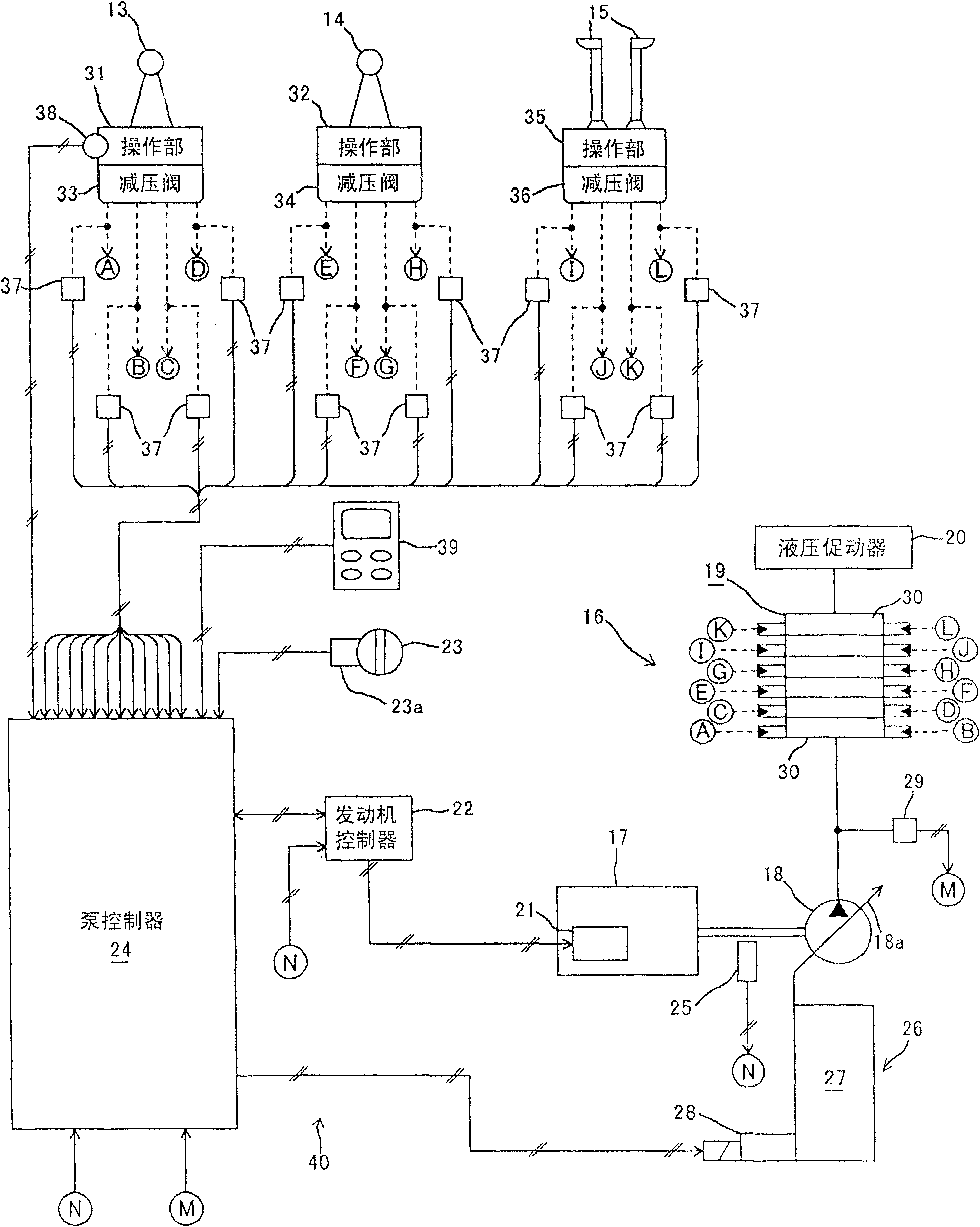

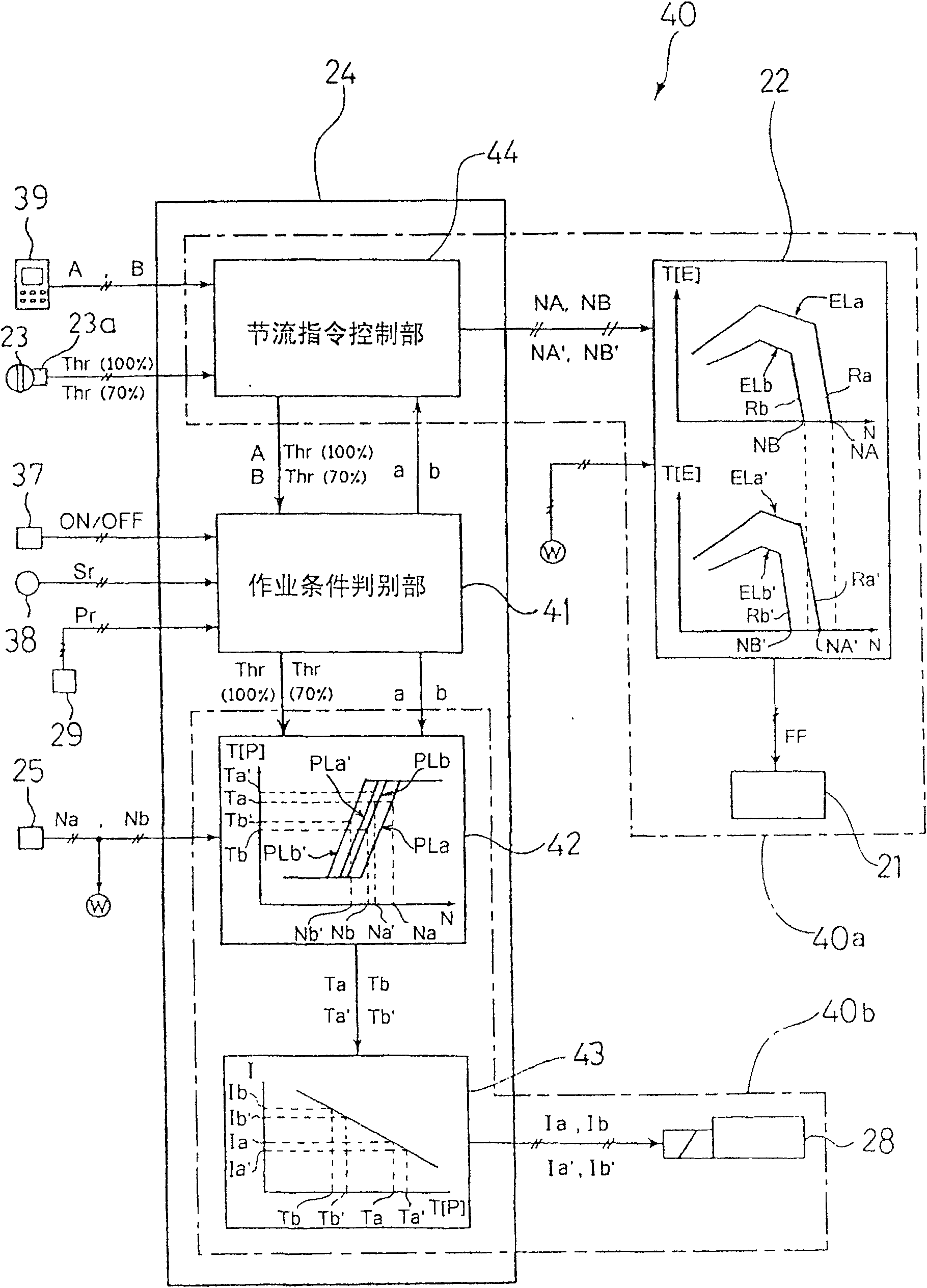

[0048] figure 1 A side view showing a hydraulic excavator according to a first embodiment of the present invention. in addition, figure 2It is an overall schematic system configuration diagram showing the hydraulic drive device of the first embodiment. in addition, image 3 A functional block diagram showing the engine-hydraulic pump control device of the first embodiment.

[0049] Such as figure 1 As shown, the hydraulic excavator of the present embodiment is provided with: an undercarriage body 2 constituted by a traveling device 2b driven by a traveling hydraulic motor 2a; a swivel device 3 driven by a swivel hydraulic motor 3a; The upper revolving body 4 arranged on the lower traveling body 2 ; the working machine 5 installed at the front center of the upper revolving body 4 ; and the cab 6 provided at the front left of the upper revolving body 4 . Here, the working machine 5 is sequentially connected to a boom 7, an arm 8, and a bucket 9 from the side of the uppe...

no. 2 approach

[0099] Next, a second embodiment of the present invention will be described. Figure 9 It is a characteristic diagram showing the relationship between the engine output torque and the hydraulic pump absorption torque in the second embodiment. in addition, Figure 10 It shows a figure explaining the variation suppression effect of the pump absorption power of 2nd Embodiment. Compared with the first embodiment, this embodiment is only different in the relationship between the output torque characteristics of the engine 17 and the absorption torque characteristics of the hydraulic pump 18, and is basically the same as the first embodiment in other respects. Since they are the same, the following description will focus on the differences from the first embodiment.

[0100] In this embodiment, when the working condition discriminated by the working condition judging unit 41 is the working condition (a), as in Figure 9 and Figure 10 As shown, the engine output torque character...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com