Method for fabricating block body of nano pure nickel material

A nanometer and bulk technology, which is applied in the field of preparing bulk nanometer pure nickel materials, can solve the problems of restricting the practical application of new nanomaterials and low productivity, and achieve the effects of being conducive to industrial development, simple equipment and low comprehensive preparation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

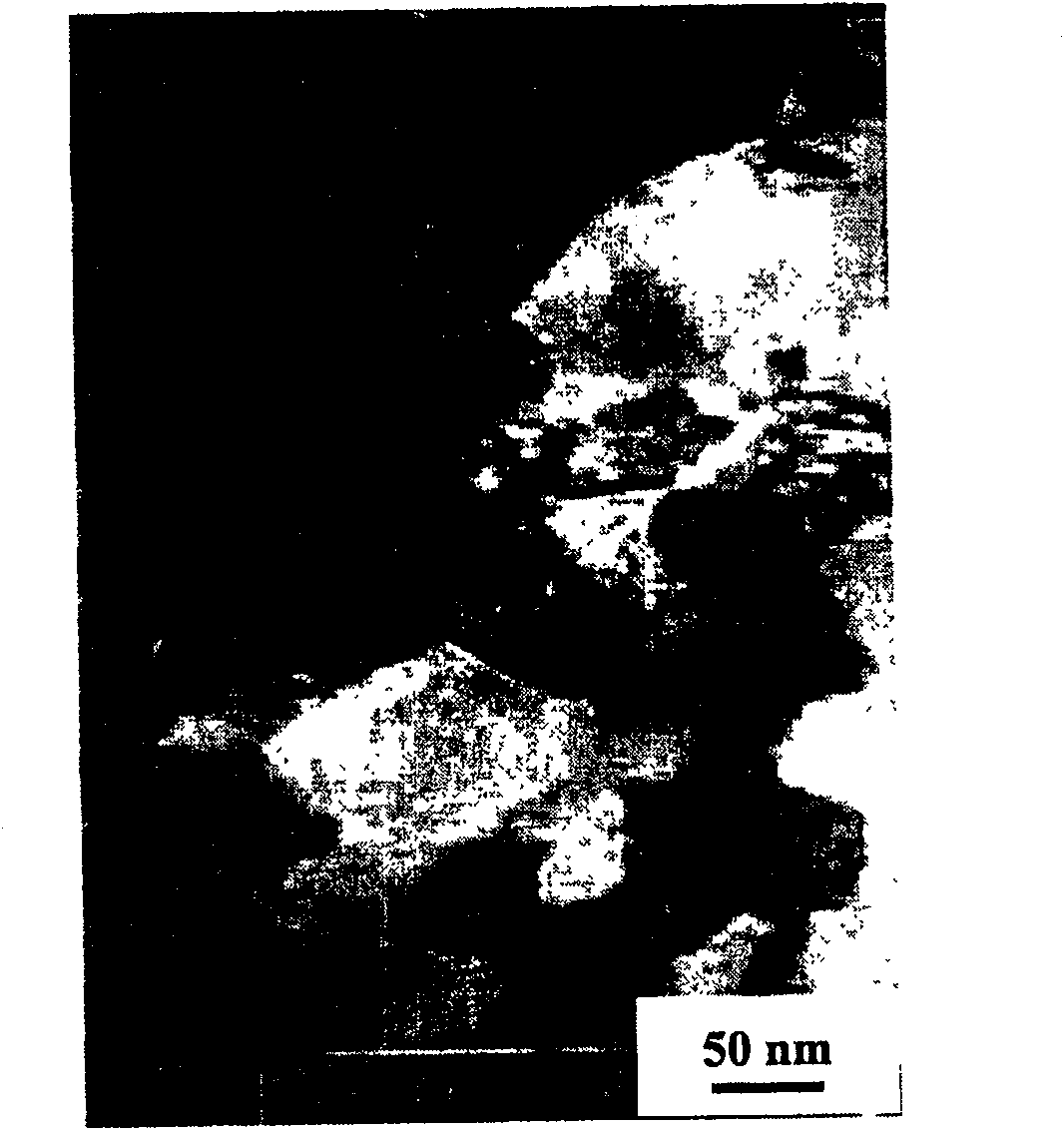

[0023] Commercially available Ni powder is selected, the powder purity is 98.2% by weight, and the particle size is 53 microns. A vertical rotor ball mill and stainless steel balls and pots were selected, the ball-to-material ratio was 35:1, the ball milling temperature was -130°C, and Ni powder with an average grain size of 28nm was formed after ball milling for 7 hours. The bulk Ni material was obtained by cold isostatic pressing with a pressure of 1450MPa. The hot isostatic pressing temperature is 1050° C., the pressure is 200 MPa, and the holding time is 60 minutes. Finally, bulk nano-Ni rods were obtained by hydrostatic extrusion. The hydrostatic extrusion temperature is room temperature, and the extrusion ratio is 4:1. The hardness of the sample reaches 315DPH, which is nearly three times that of the coarse-grained material.

Embodiment 2

[0025] Commercially available Ni powder is selected, the powder purity is 98% by weight, and the particle size is 75 microns. A vertical rotor ball mill and stainless steel balls and pots were selected, the ball-to-material ratio was 40:1, the ball milling temperature was -140°C, and Ni powder with an average grain size of 11 nm was formed after ball milling for 9 hours. The bulk Ni material was obtained by cold isostatic pressing with a pressure of 1600MPa. The hot isostatic pressing temperature is 1100° C., the pressure is 150 MPa, and the holding time is 50 minutes. Finally, bulk nano-Ni rods were obtained by hydrostatic extrusion. The hydrostatic extrusion temperature is room temperature, and the extrusion ratio is 3:1. The sample hardness reaches 328DPH.

Embodiment 3

[0027] Commercially available Ni powder is selected, the powder purity is 98.5% by weight, and the particle size is 180 microns. A high-energy horizontal rotor ball mill and stainless steel balls and tanks were selected, the ball-to-material ratio was 50:1, the ball milling temperature was -150°C, and Ni powder with an average grain size of 32nm was formed after ball milling for 2 hours. The bulk Ni material was obtained by cold isostatic pressing at a pressure of 1400 MPa. The hot isostatic pressing temperature is 1000° C., the pressure is 250 MPa, and the holding time is 70 minutes. Finally, bulk nano-Ni rods were obtained by hydrostatic extrusion. The hydrostatic extrusion temperature is room temperature, and the extrusion ratio is 5:1. The sample hardness reaches 337DPH.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com