Apparatus for depositing atomic layer using gas separation type showerhead

A technology of atomic layer deposition and gas separation, applied in coatings, electrical components, gaseous chemical plating, etc., can solve problems such as reduced plasma efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

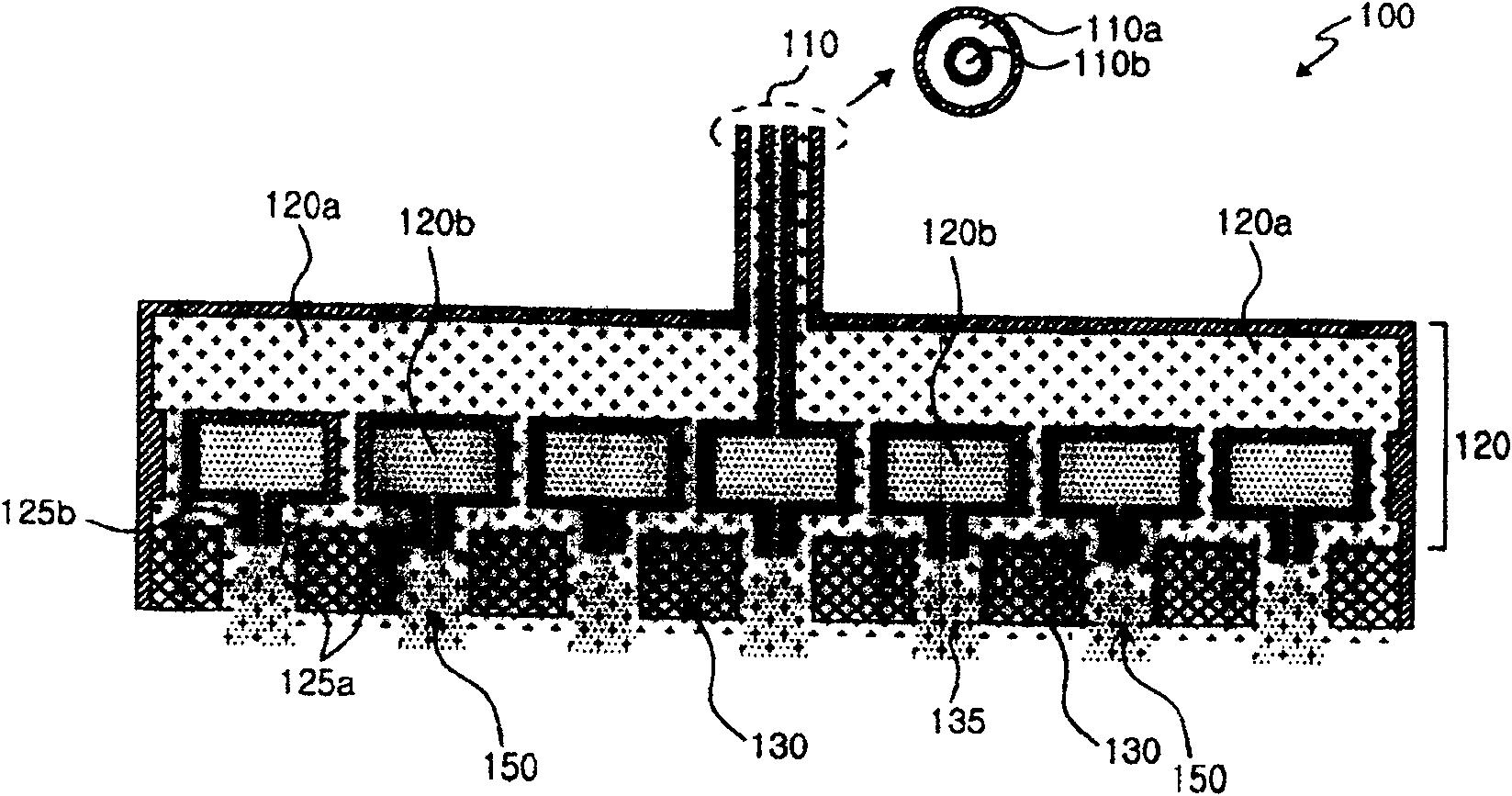

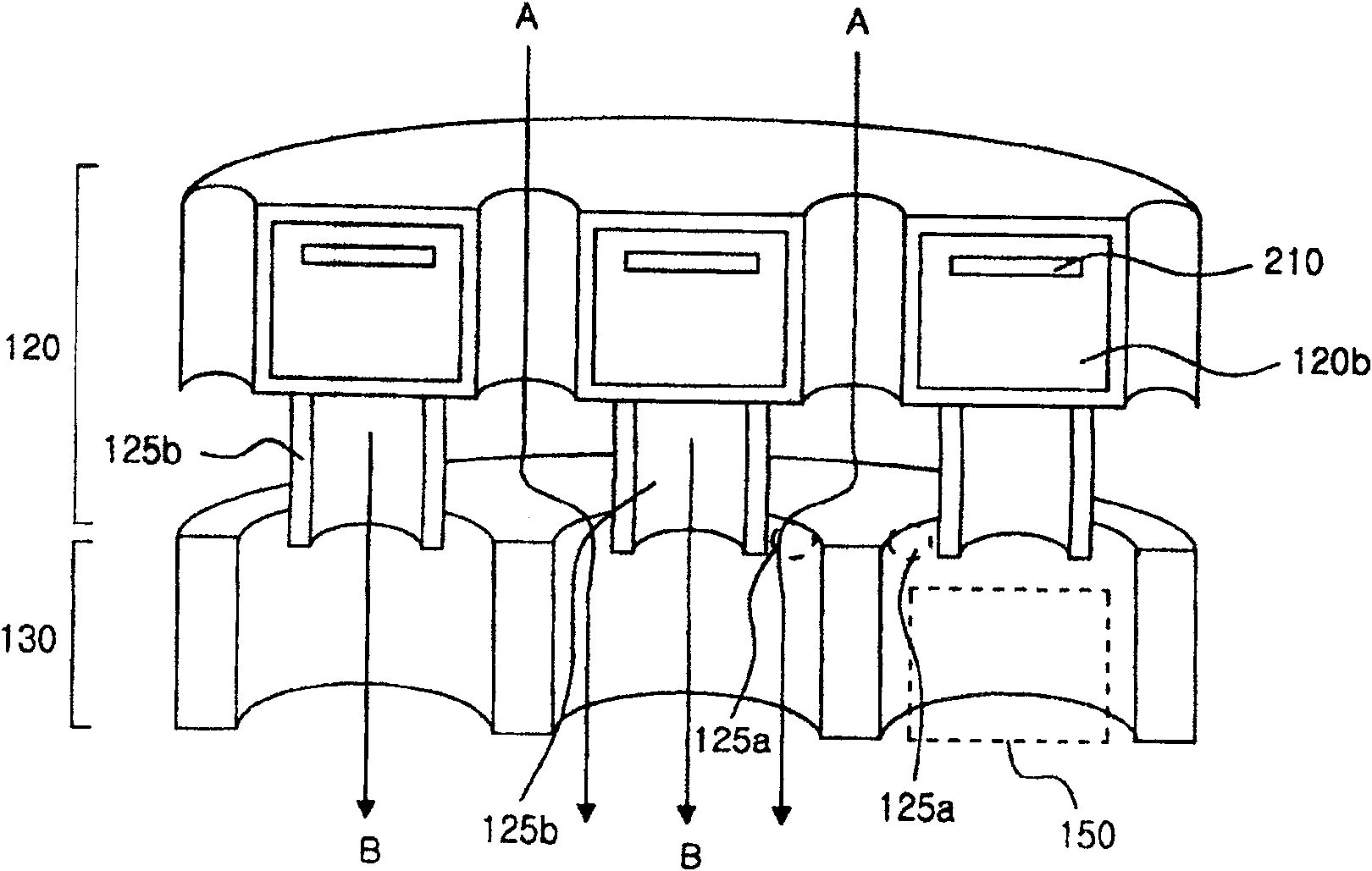

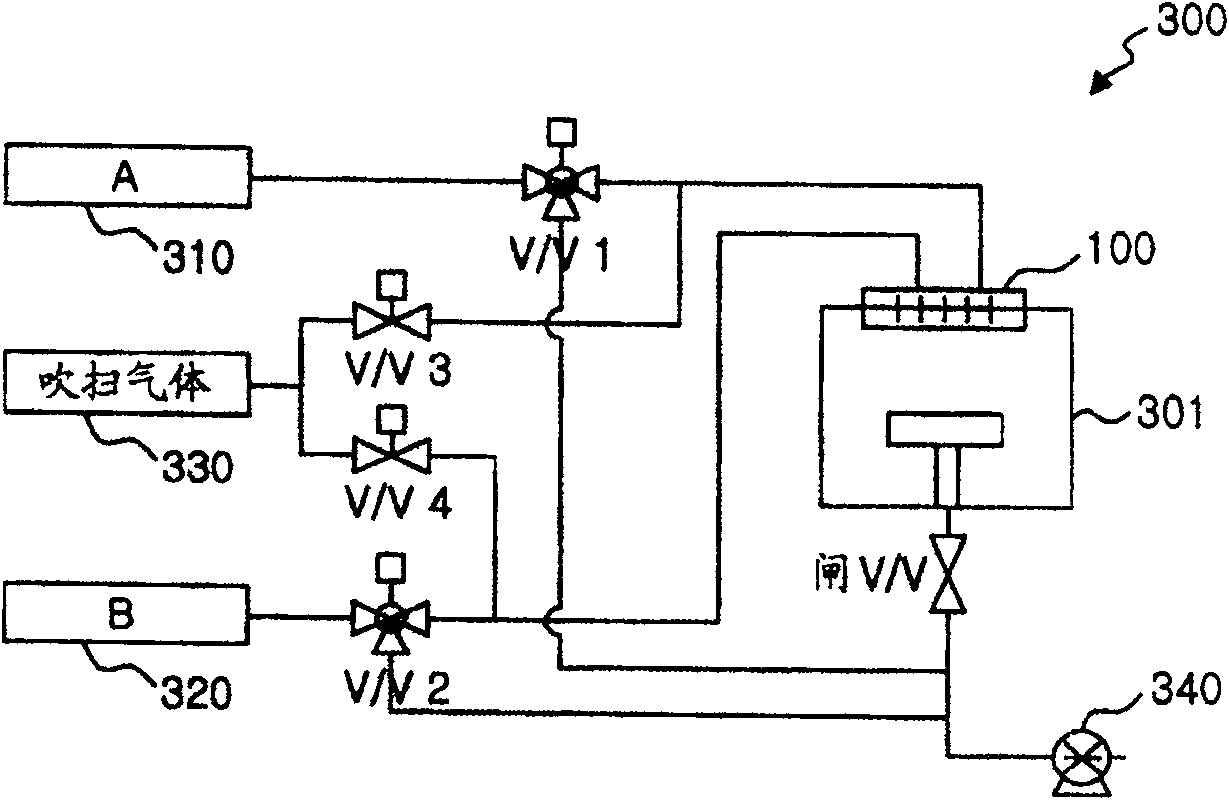

[0022] figure 1 A gas separation type shower head used in the present invention is shown. figure 1 The illustrated gas separation type showerhead 100 includes a gas supply module 110 , a gas separation module 120 and a gas injection module 130 .

[0023] The gas supply module 110 includes an outer supply pipe 110a and an inner supply pipe 110b separated from each other. The first precursor A is supplied to the outer supply tube 110a, while the second precursor B is supplied to the inner supply tube 110b.

[0024] The gas separation module 120 includes a first dispersion area 120a connected to the outer supply pipe 110a and a second dispersion area 120b connected to the inner supply pipe 110b. refer to figure 1 , the first precursor A is supplied to the outer supply pipe 110a and dispersed in the first dispersion area 120a, and the second p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com