Semiconductor chip automatic centering mechanism

An alignment mechanism and automatic alignment technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as wafer difficulty, and achieve the effect of reducing errors and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

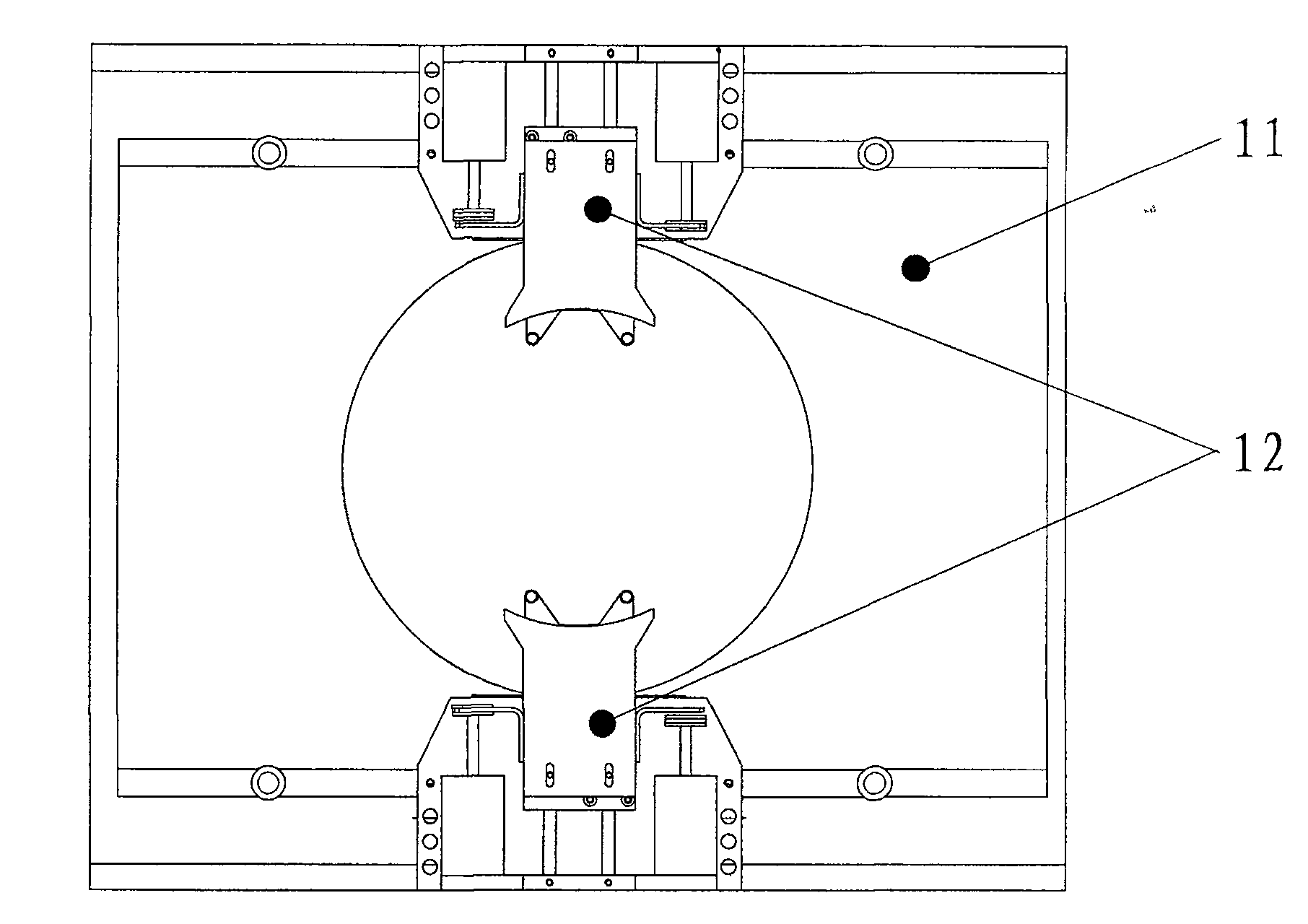

[0019] like figure 1 As shown, two centering mechanisms 12 (that is, the present invention) form a group, which are respectively installed on both sides of the wafer processing unit 11. When the wafer is transported to the central position of the wafer processing unit, the two centering mechanisms move synchronously to complete the alignment. Wafer centering action. The centering process is divided into two steps: splicing and centering. The centering mechanism can exchange the size of the centering block and the splicing plate according to the size of the processed wafer.

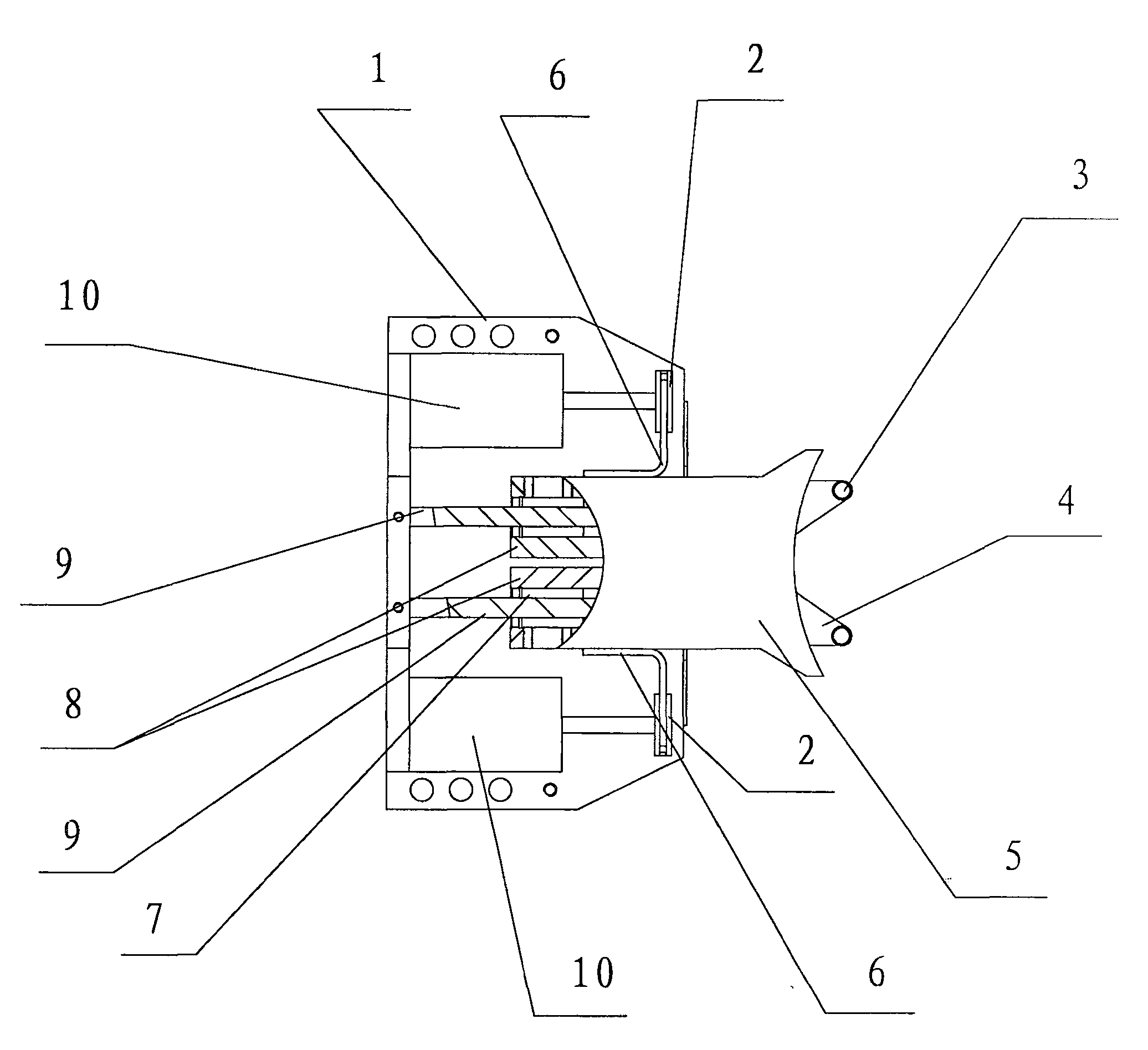

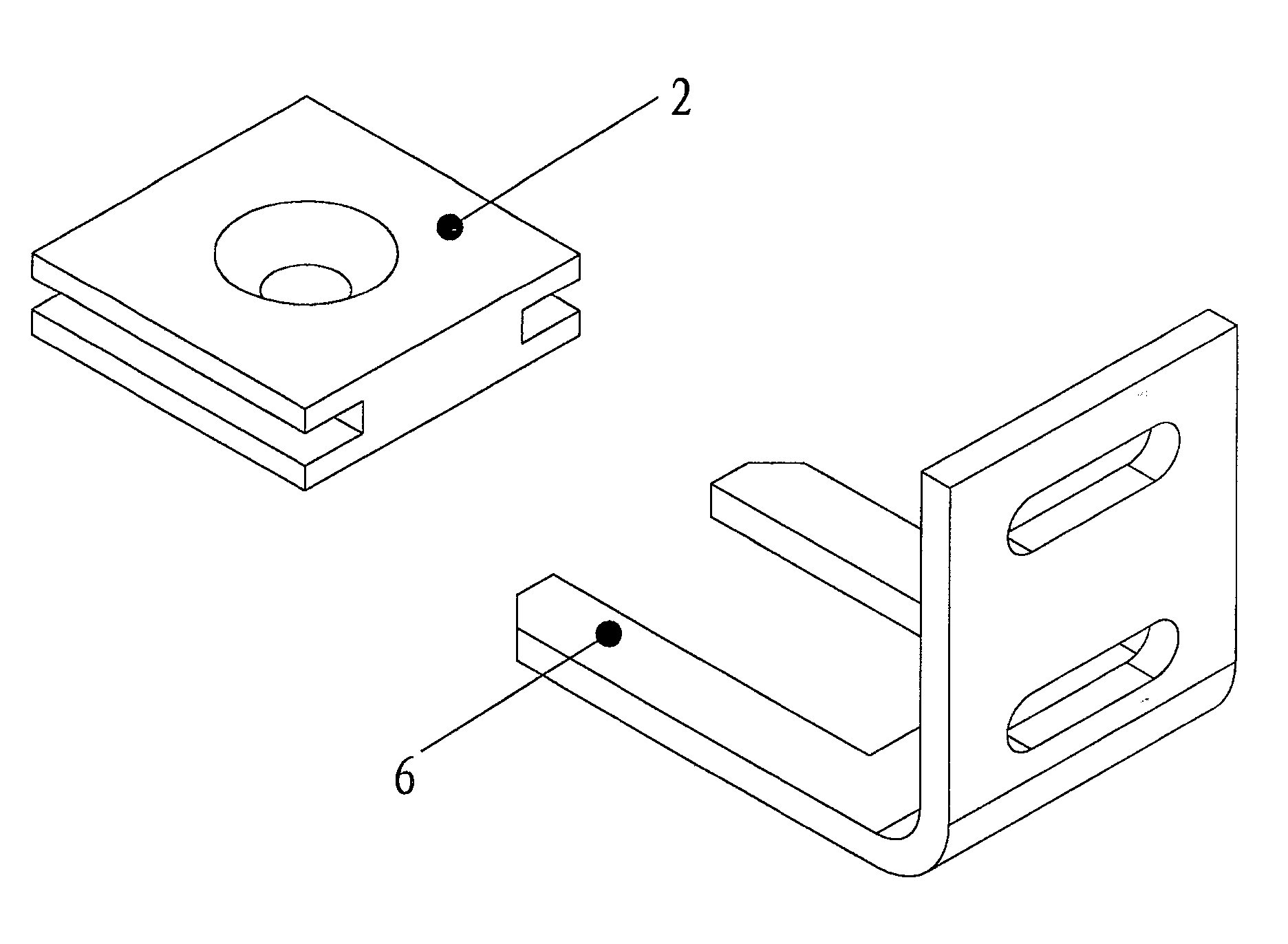

[0020] like figure 2 As shown, the centering mechanism of the present invention is provided with a bottom plate 1, a fixed block 2, a pillar 3, a joint plate 4, a centering block 5, a connecting plate 6, a linear bearing 7, a bearing seat 8, a guide rod 9, a cylinder 10, etc. The two cylinders 10 are directly fixed on the bottom plate 1, the joint plate 4 is fixed on one bearing seat 8 by screws, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com