Piezoelectric ceramic fibre containing metal core of partly painted electrode

A piezoelectric fiber, metal core technology, applied in piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc. and other problems to achieve the effect of overcoming application defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

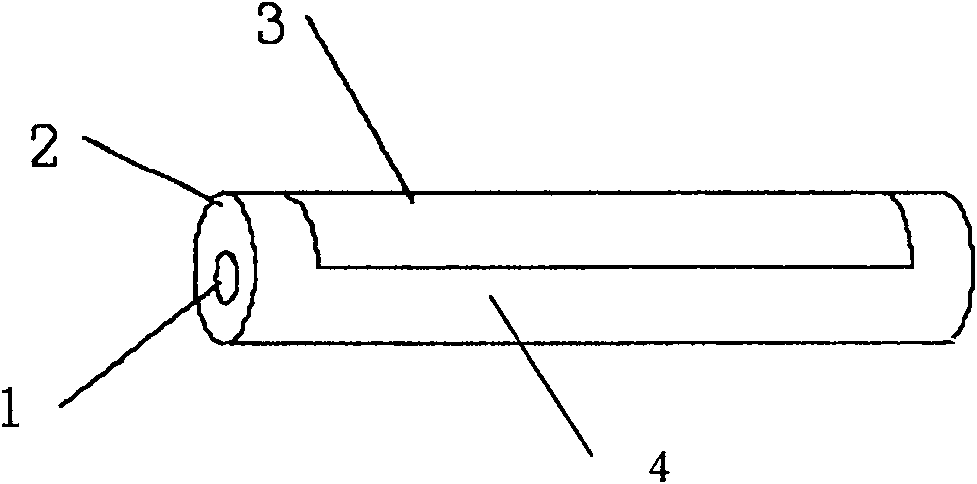

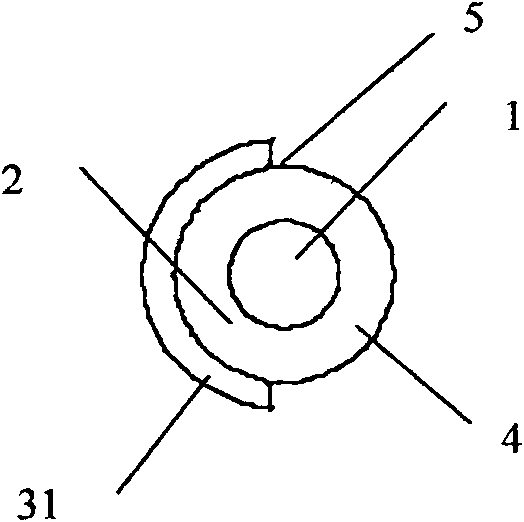

[0021] Embodiment one: if figure 1 , figure 2 As shown, the piezoelectric fiber containing a metal core of the partially coated electrode of this embodiment includes a metal core 1, a piezoelectric material 2 coated on the metal core 1, and a coated electrode 3 coated on the outer surface of the piezoelectric material 2 , the surface of the piezoelectric material 2 includes a coated electrode portion 3 and an uncoated electrode portion 4, the coated electrode portion 3 is a coated electrode 31, which partially covers the piezoelectric material 2 along the direction in which the piezoelectric fiber containing the metal core extends The surface; Wherein, coating electrode part 3 occupies half of the surface area of piezoelectric material 2;

[0022] The diameter of the metal core 1 is 25 microns, and the material of the metal core 1 is platinum;

[0023] The section of the piezoelectric fiber containing the metal core of the partially coated electrode of this embodiment is ...

Embodiment 2

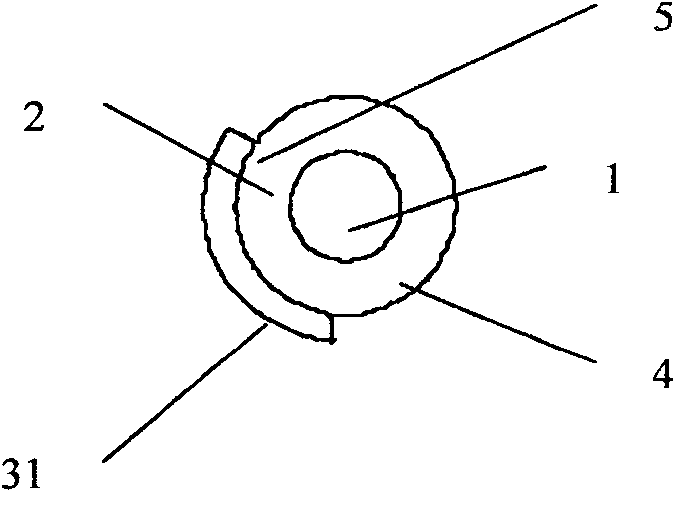

[0029] Such as figure 1 , image 3 As shown, the piezoelectric fiber containing a metal core of the partially coated electrode of this embodiment includes a metal core 1, a piezoelectric material 2 coated on the metal core 1, and a coated electrode 3 coated on the outer surface of the piezoelectric material 2 , the surface of the piezoelectric material 2 includes a coated electrode portion 3 and an uncoated electrode portion 4, the coated electrode portion 3 is a coated electrode 31, which partially covers the piezoelectric material 2 along the direction in which the piezoelectric fiber containing the metal core extends The surface; Wherein, the coated electrode part 3 occupies one-third of the surface area of the piezoelectric material 2;

[0030] The piezoelectric fiber containing the metal core of the partially coated electrode in this embodiment, the diameter of the metal core 1 is 10200 microns, and the metal core 1 is made of a high temperature resistant material, suc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com