Preparation method and application of magnolol-carboxyl terminal polyamide controlled release formulation

A technology of terminated polyamide and magnolol, which is applied in the field of oral medical materials, can solve the problems of easy oxidation of phenolic hydroxyl groups, variability of preparation storage, and insoluble drugs in water, etc., to prolong the release time, improve solubility, and effect strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A preparation method of magnolol-carboxyl-terminated polyamide slow-release agent, comprising the following steps:

[0033] (1) Using the mixed solvent method, mix dimethyl sulfoxide and double distilled water at a volume ratio of 1:7 to obtain a mixed solution;

[0034] (2) Add 10 mL of the mixed solution obtained in step (1) into a 15 mL centrifuge tube, add 60 mg of carboxy-terminal polyamide at a ratio of 6 mg / mL, and add 20 mg of magnolol at a ratio of 2.0 mg / mL;

[0035] (3) The solution obtained in step (2) was ultrasonically oscillated, that is, after the centrifuge tube was closed, the centrifuge tube was ultrasonically oscillated at 37°C for 1 hour, then a stirrer was placed in the centrifuge tube, and after closure, it was placed in a constant temperature mixer at 37°C and stirred at 200rpm for 72 hours;

[0036] (4) Add 8 mL of water to precipitate the excess drug, centrifuge at 3000 rpm for 10 min to remove the precipitate, and freeze-dry the supernatant to...

Embodiment 1

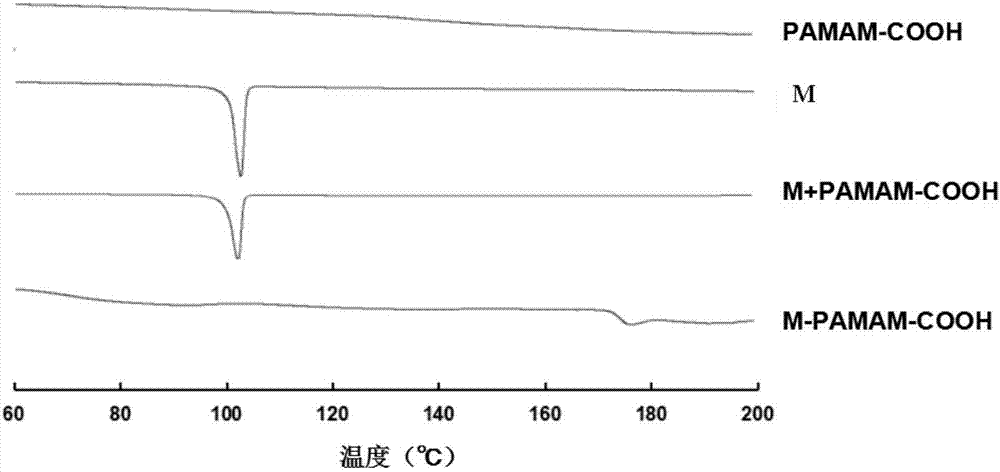

[0039] Differential scanning calorimetry DSC detection was carried out, and the samples to be tested were divided into four groups: carboxy-terminal polyamide (PAMAM-COOH), magnolol (M), a mixture of magnolol and carboxy-terminal polyamide (M+ PAMAM- COOH) and M-PAMAM-COOH.

[0040] The specific process is as follows: Weigh 5 mg of each group of samples, put them into aluminum sample dishes and seal them, and perform DSC detection; the detection conditions are: gas pressure 0.06Mpa~0.1Mpa, gas flow rate 20mL / min~40mL / min, scan the samples , scan the sample at a heating rate of 10°C / min, the scanning range is 50°C~300°C, and the scanning results are analyzed and processed by Pyris Manager software; figure 1 As shown, it can be seen from the figure: PAMAM-COOH has no peak in the scanning temperature range, indicating that there is no endothermic or exothermic in PAMAM-COOH in this temperature range; the literature suggests that the DSC spectrum of magnolol is around 103°C The e...

Embodiment 2

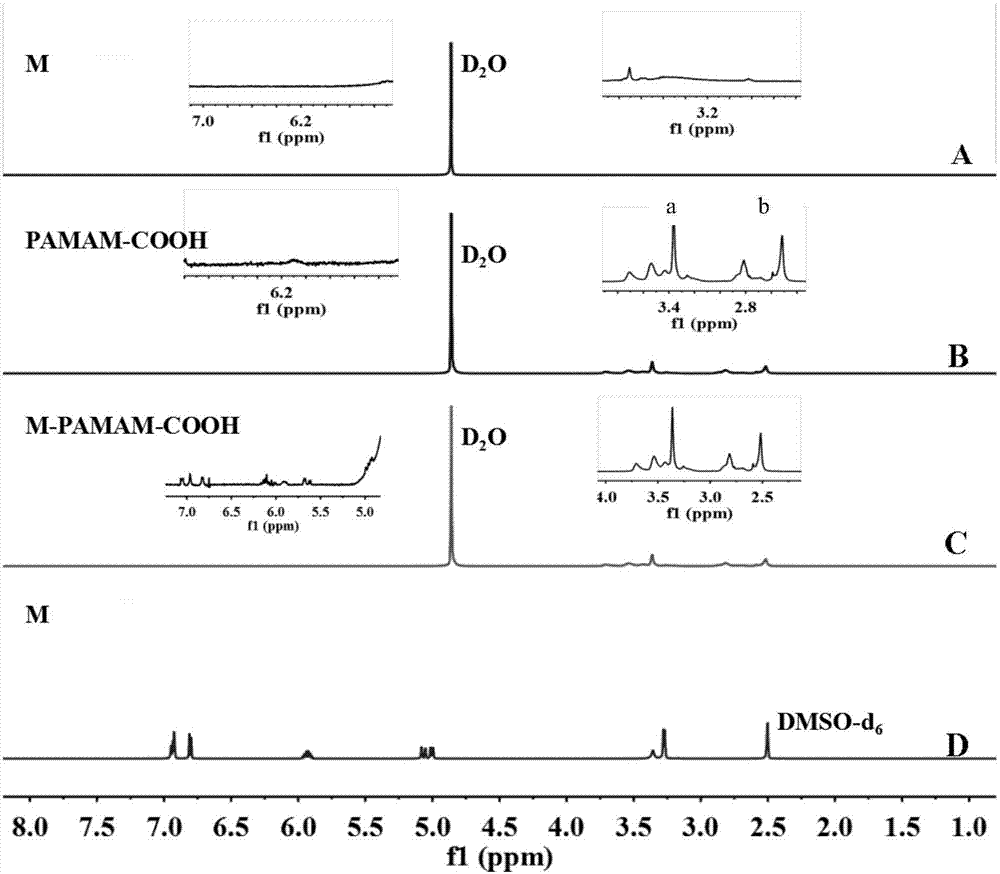

[0042] 1H NMR detection was carried out, and the samples to be tested were divided into three groups: carboxy-terminal polyamide (PAMAM-COOH), magnolol (M) and M-PAMAM-COOH;

[0043] The specific process is as follows: each group of samples weighed 5 mg respectively, and the weighed samples were dissolved in 0.6 mL of heavy water (D 2 O), M was dissolved in deuterated dimethyl sulfoxide (DMSO-d 6 ); then add the liquid into the NMR tube, put the NMR tube into the NMR spectrometer, select 1 H detects the sample to obtain a nuclear magnetic spectrum, and uses MestReNova software to analyze and process the spectrum; figure 2 It can be seen from the figure that: figure 2 The middle is the nuclear magnetic resonance spectrum of each group of samples, A is the nuclear magnetic spectrum of magnolol, and the solvent is D 2 O, D appears at 4.86ppm in the figure 2 The solvent peak of O, the peak of magnolol appears at 3.25ppm, and no peak appears at other positions; B is the NMR s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com