A kind of separation and purification method of methionine

A technology for separation and purification of methionine, applied in chemical instruments and methods, organic chemistry, preparation of organic compounds, etc., can solve problems such as low desalination rate, multiple energy sources, and impact on the surrounding environment, and achieve high purity of inorganic salts, simple operation, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

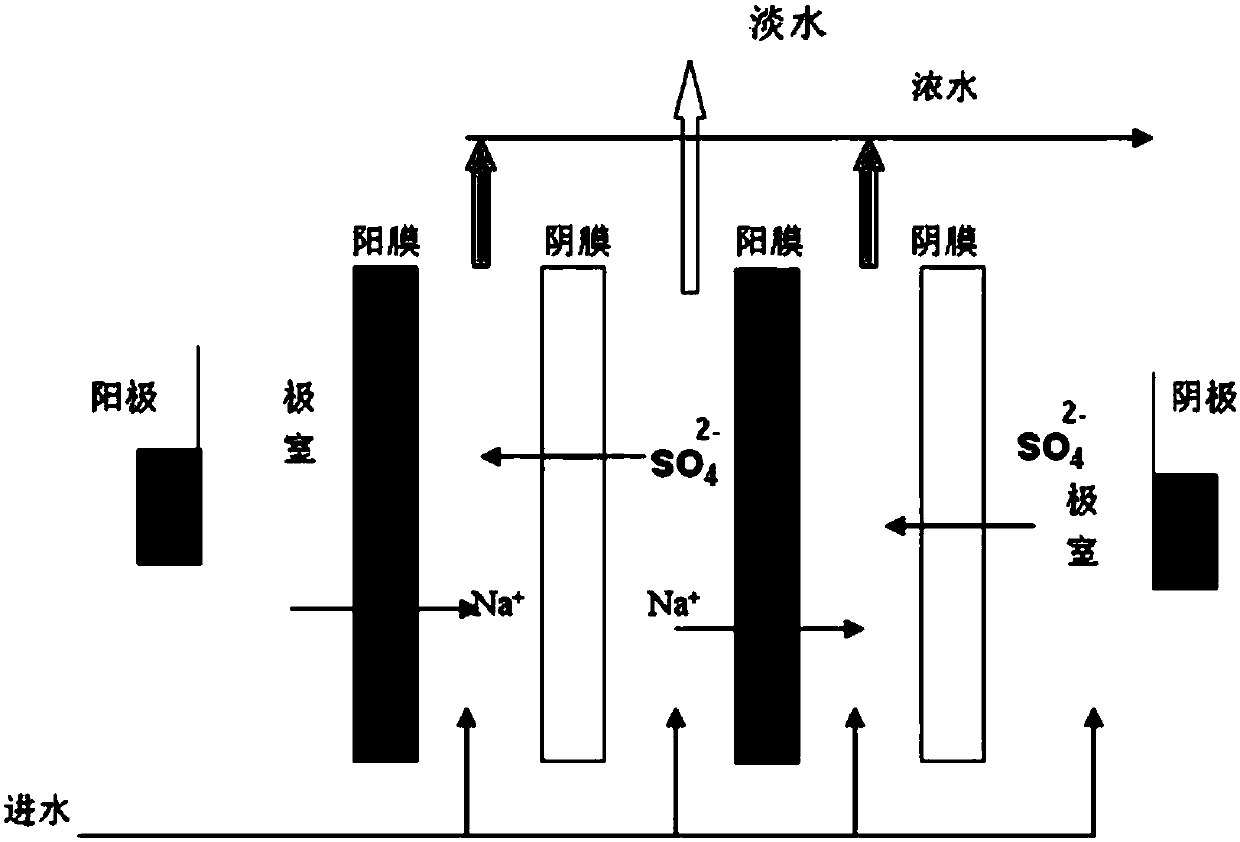

Embodiment 1

[0032]Concentrate the sodium sulfate mother liquor containing methionine to a sodium sulfate content of 20wt%, wherein the methionine content is about 2wt%, sodium formate, sodium acetate, sodium propionate, etc. are about 1wt% in total, and the pH of the feed solution is 5.5, totaling 10L. Sodium sulfate mother liquor containing methionine passes through a precision filter and enters homogeneous membrane electrodialysis for desalination treatment at a temperature of 35°C. Homogeneous membrane electrodialysis has three chambers, namely polar liquid chamber, feed liquid chamber (dilute chamber) and In the receiving chamber (concentrated chamber), during the desalination process, due to the migration of sodium sulfate to the concentrated chamber, the pH in the feed liquid chamber will increase, and sulfuric acid needs to be added to keep the pH at about 5.5. When the sodium sulfate in the feed liquid chamber is reduced to 5%, the material in the feed liquid chamber is transferred...

Embodiment 2

[0035] Concentrate the sodium sulfate mother liquor containing methionine to a sodium sulfate content of 25wt%, wherein the methionine content is about 2.4wt%, sodium formate, sodium acetate, sodium propionate, etc. are about 1wt% in total, and the pH of the feed solution is 5.2, a total of 10L. Sodium sulfate mother liquor containing methionine passes through a precision filter and enters homogeneous membrane electrodialysis for desalination treatment at a temperature of 35°C. Homogeneous membrane electrodialysis has three chambers, namely polar liquid chamber, feed liquid chamber (dilute chamber) and In the receiving chamber (concentrated chamber), during the desalination process, due to the migration of sodium sulfate to the concentrated chamber, the pH in the feed liquid chamber will increase, and sulfuric acid needs to be added to keep the pH at about 5.2. When the sodium sulfate in the feed liquid chamber is reduced to 4%, the material in the feed liquid chamber is transf...

Embodiment 3

[0038] Concentrate the sodium sulfate mother liquor containing methionine to a sodium sulfate content of 28wt%, wherein the methionine content is about 3.0wt%, sodium formate, sodium acetate, sodium propionate, etc. are about 1wt% in total, and the pH of the feed solution is 5.1, a total of 10L. Sodium sulfate mother liquor containing methionine passes through a precision filter and enters homogeneous membrane electrodialysis for desalination treatment at a temperature of 35°C. Homogeneous membrane electrodialysis has three chambers, namely polar liquid chamber, feed liquid chamber (dilute chamber) and In the receiving chamber (concentrated chamber), during the desalination process, due to the migration of sodium sulfate to the concentrated chamber, the pH in the feed liquid chamber will increase, and sulfuric acid needs to be added to keep the pH at about 5.1. When the sodium sulfate in the feed liquid chamber is reduced to 6%, the material in the feed liquid chamber is transf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com