Fuel cell module

A fuel cell and fuel cell unit technology, applied in the direction of fuel cells, fuel cell additives, fuel cell grouping, etc., can solve the problems of reduced reliability of gas sealing, leakage of oxygen-containing gas, increased assembly processes, etc., and achieve heat exchange efficiency Effects of rise, thermal independence, temperature rise, and assembly process reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] Embodiments of the present invention will be described below with reference to the drawings. The fixed oxide fuel cell module of the present invention is suitable for use in distributed power generation, especially a household fuel cell module performing a load following operation of 0.5 to 1.5 kW.

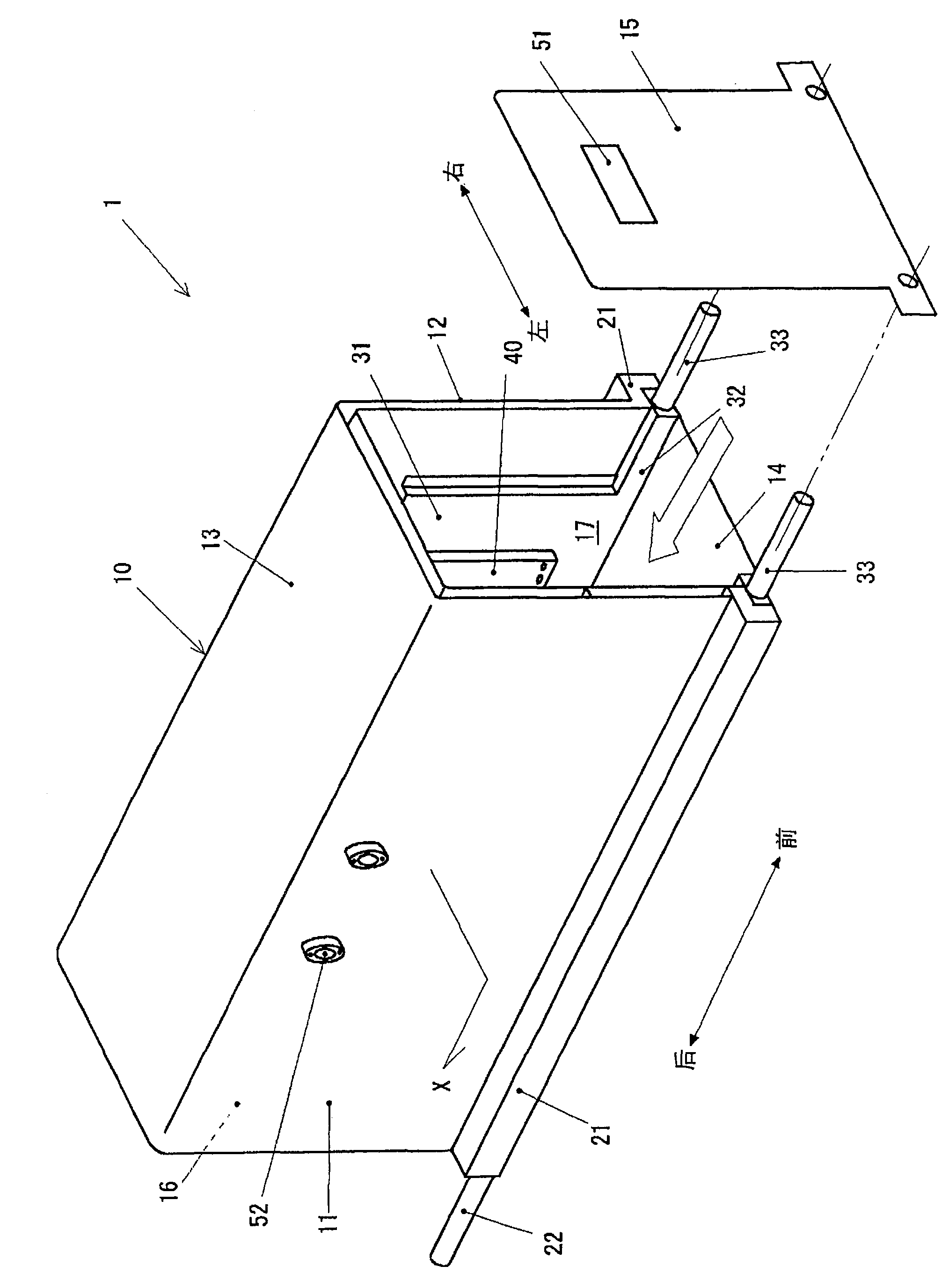

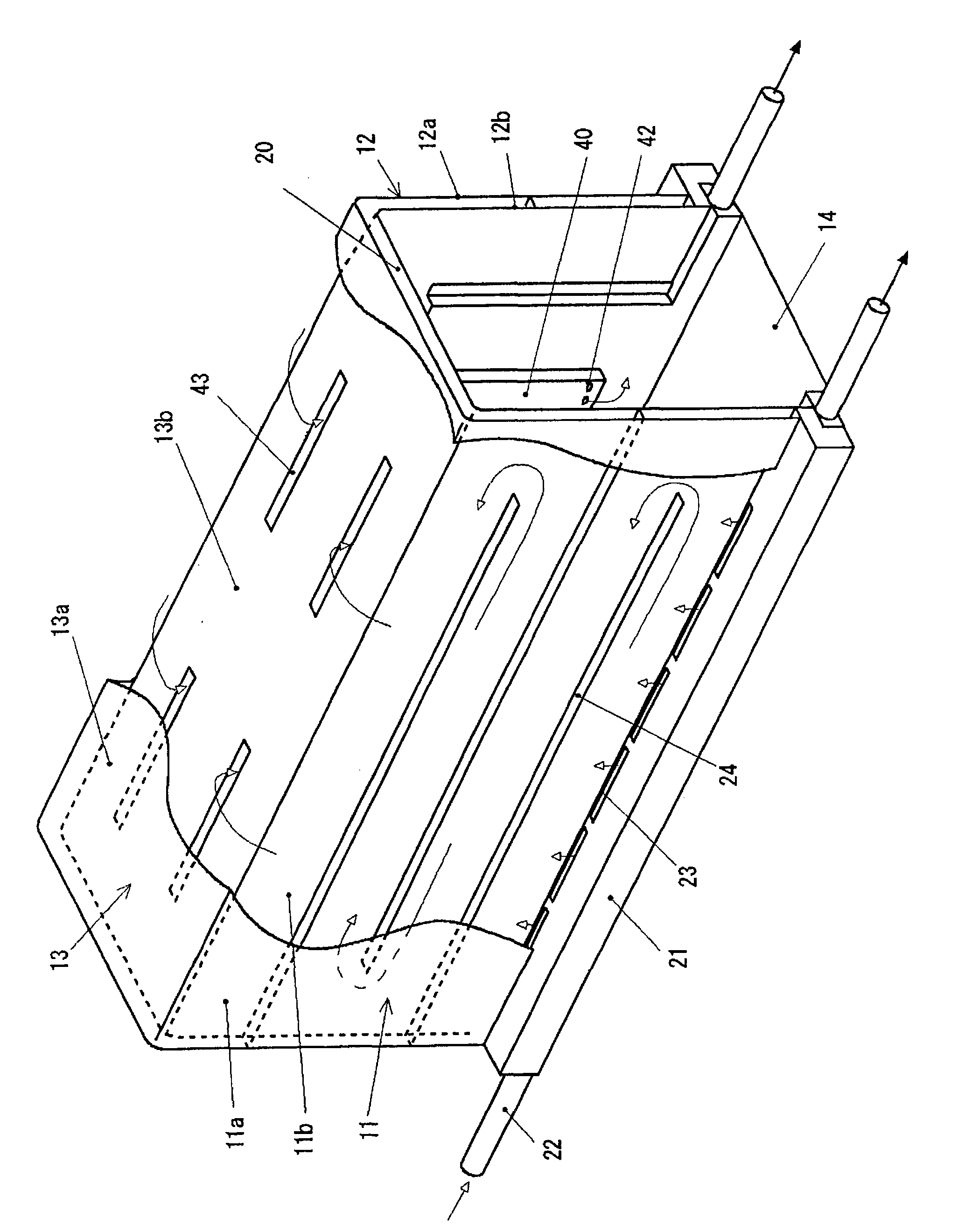

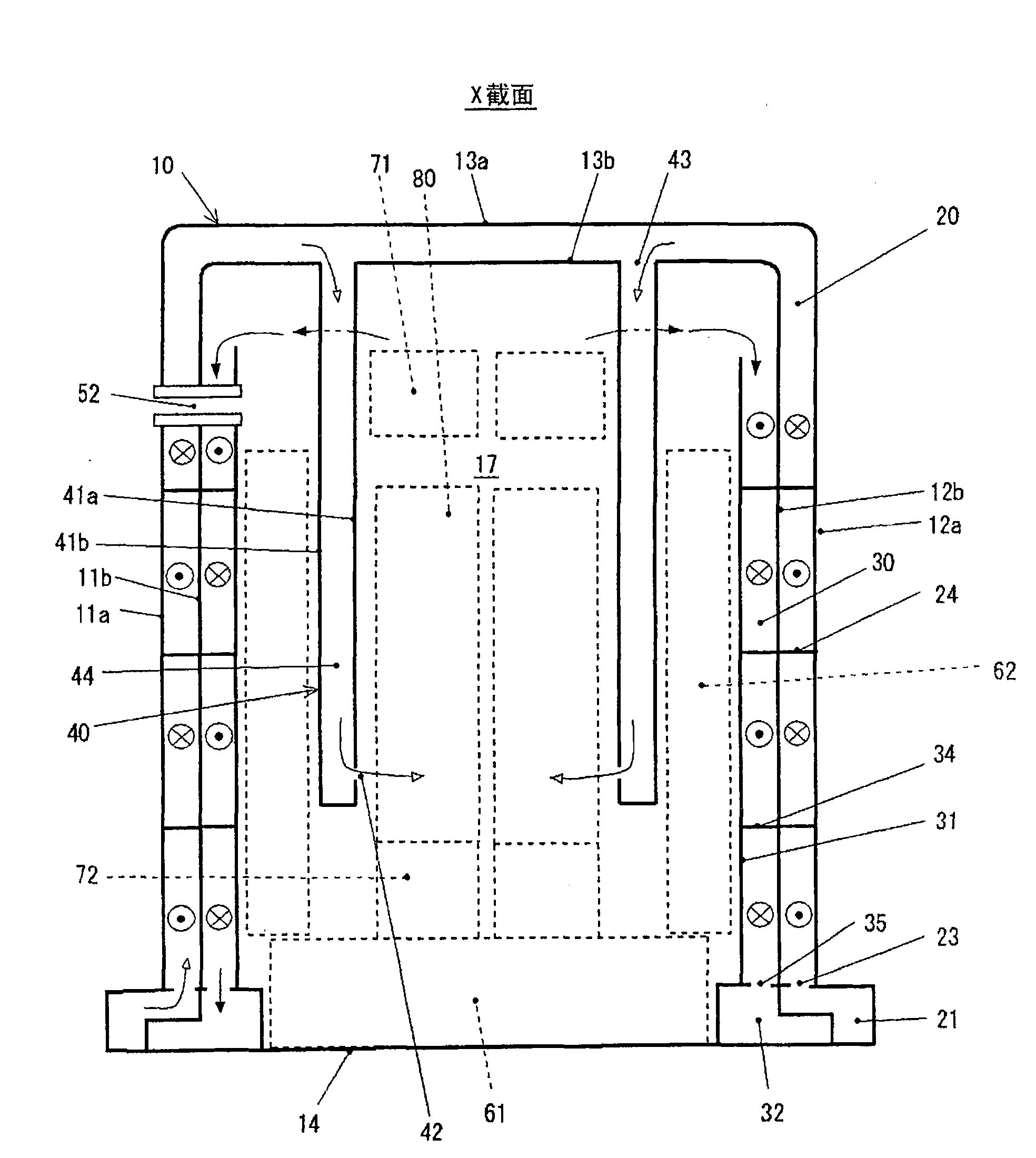

[0079] figure 1 It is an external perspective view of an embodiment of the fixed oxide fuel cell module of the present invention. The fuel cell module 1 includes a substantially rectangular parallelepiped casing 10 , and the casing 10 houses a power generation chamber 17 . figure 1It is not shown in the figure, but a battery pack (cell stack) in which a plurality of fixed oxide fuel cell units are arranged in a row is arranged in the power generation chamber 17, and a communication device (fuel gas box) and / or a reformer, etc. The fuel cell stack device constituted (details thereof will be described later). Hereinafter, regarding the housing 10 , the directions indicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com