Balanced rotary engine

A rotating engine and balanced technology, applied in the direction of machines/engines, mechanical equipment, etc., can solve the problems of loss of efficiency, reduction of effective chamber mixed gas entry time, engine ventilation and compression, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

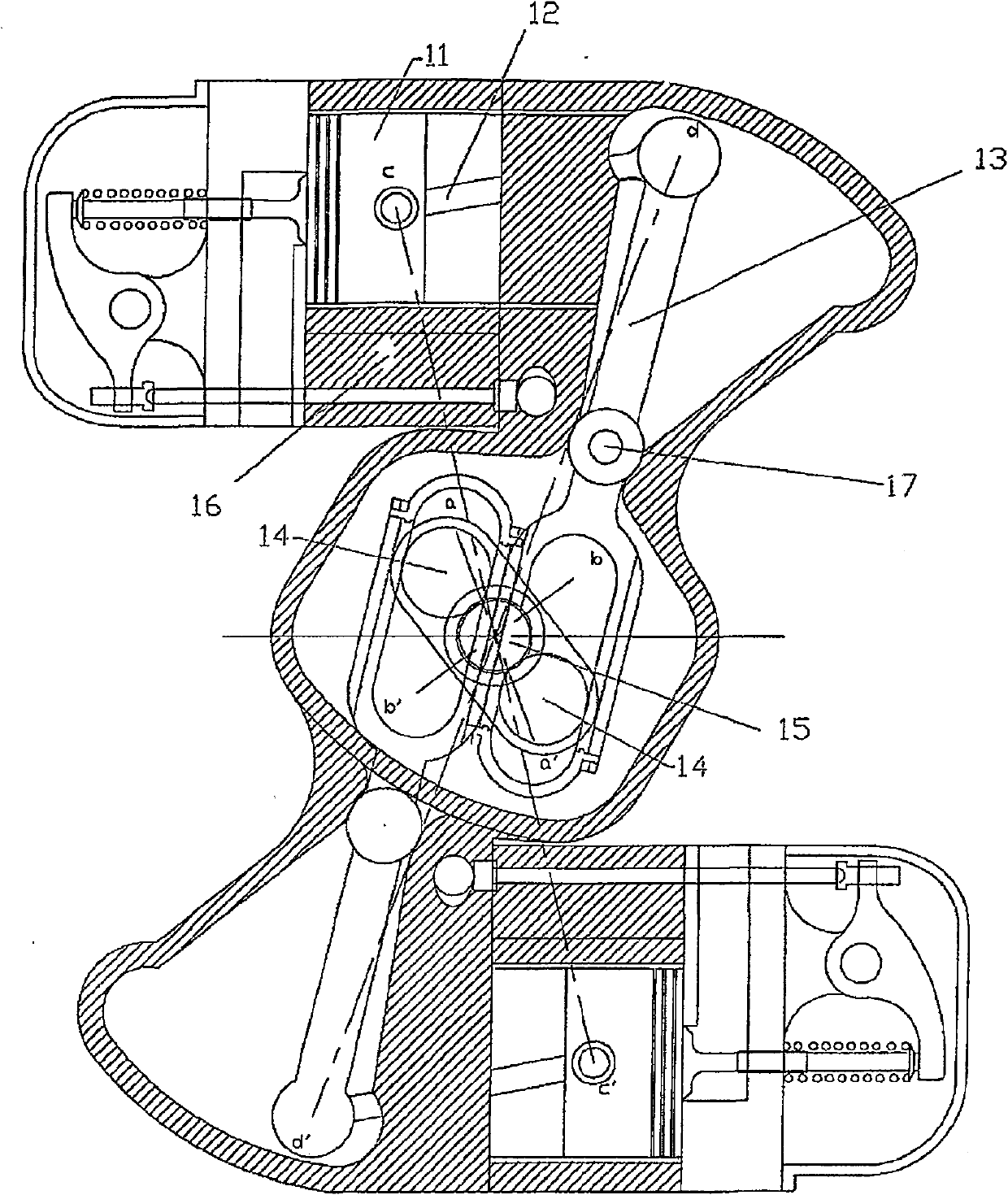

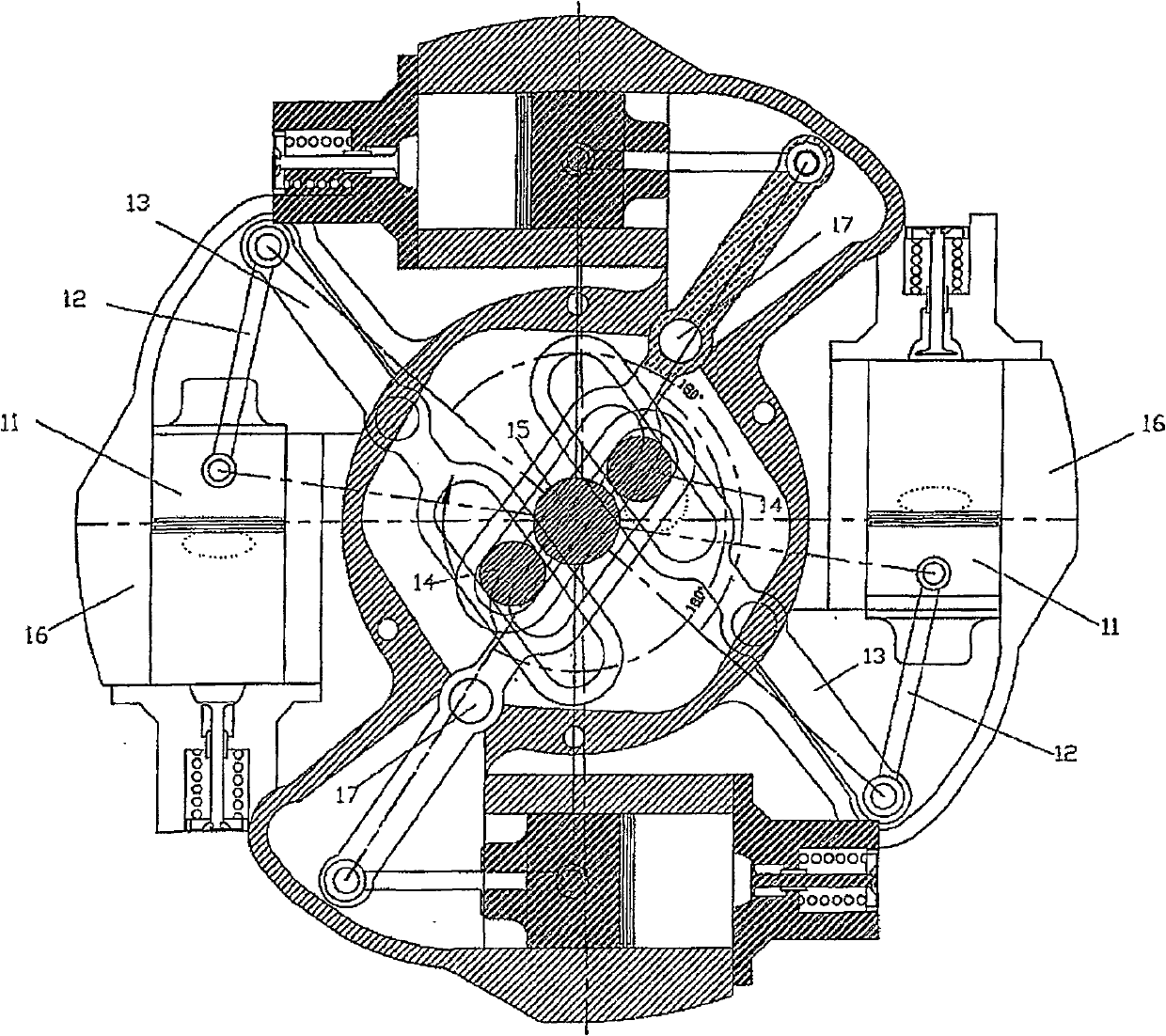

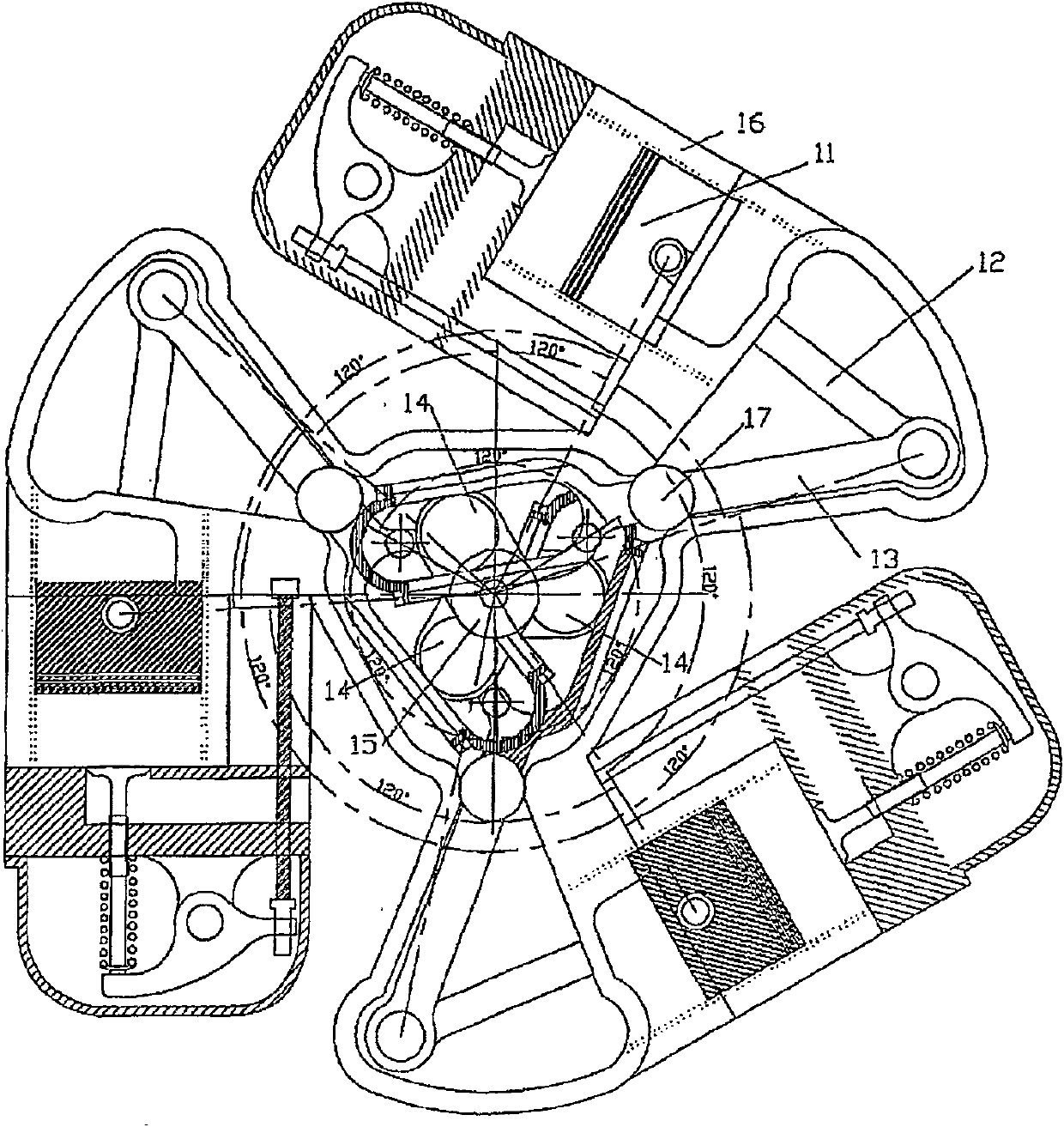

[0026] The present invention relates to a balanced rotary engine consisting of a rotary engine including tangential pistons which improve engine performance, facilitate lubrication of engine components, and enable use at high speeds of rotation. The composition of the components is such that the engine is self-powered, and air or a mixture is drawn directly from the rear of the cylinder and injected into the combustion chamber of said cylinder or a combustion chamber adjacent to the cylinder, which air or mixture is suitable for full use of combustion Two-stroke operation of the chamber, even mixtures that spontaneously explode once a moderately high pressure is reached (Diesel cycle).

[0027] As shown in the accompanying drawings, there are two preferred embodiments of the balanced rotary engine. The first embodiment shows a balanced rotary engine ( figure 1 , figure 2 and image 3 ), while the second embodiment shows a self-powered balanced rotary engine ( Figure 4 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com