Axis system based on five-axis linkage machining center and the five-axis linkage machining center

A five-axis linkage and processed technology, which is applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problem of affecting the positioning accuracy and acceleration performance of the swinging B-axis, affecting the five-axis linkage performance of the whole machine, and low moving acceleration To achieve good acceleration performance and dynamic response characteristics, avoid the influence of thermal deformation of machine tools, and protect expensive blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

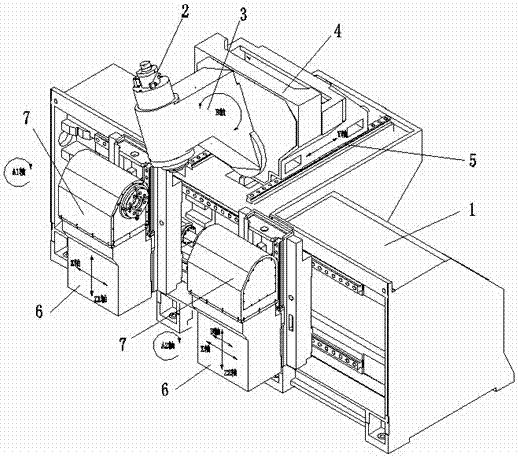

[0036] Such as figure 1 As shown, this embodiment provides a five-axis linkage machining center, which is mainly used for machining blade parts, and mainly includes a bed, a main shaft, a headstock and five shaft systems, wherein the bed can adopt the existing The bed and its suitable supporting parts, the structure of the bed is not particularly limited; the spindle and the headstock are supporting facilities, which can adopt the existing mature spindle and headstock structure, compared with the existing five-axis linkage machining center , the biggest improvement of this embodiment lies in the arrangement of the five shaft systems.

[0037] The five axes of the five-axis linkage machining center are: three linear axes: X-axis, Y-axis and Z-axis, one rotary axis: A-axis, one swing axis: B-axis; among them, X-axis, Z-axis and A-axis The axes are arranged below the machine tool, and the Y-axis and B-axis are arranged above the machine tool. The spindle and tool are driven to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com