Urban rail door sheet

A technology for urban rails and door panels, applied in door devices, railway car body parts, transportation and packaging, etc., can solve the problems of difficult to guarantee the life of door panels, easy aging of adhesives, uneven heating of parts, and achieve uniform strength and rigidity. , The quality distribution is uniform, the overall beautiful effect of the door panel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

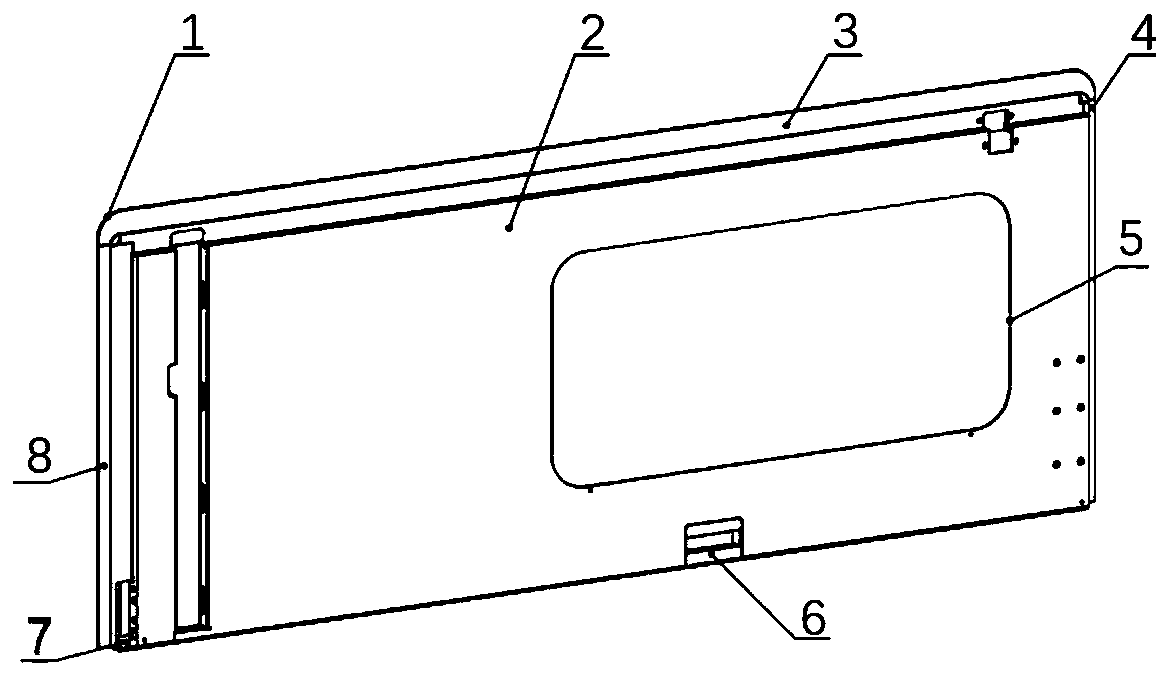

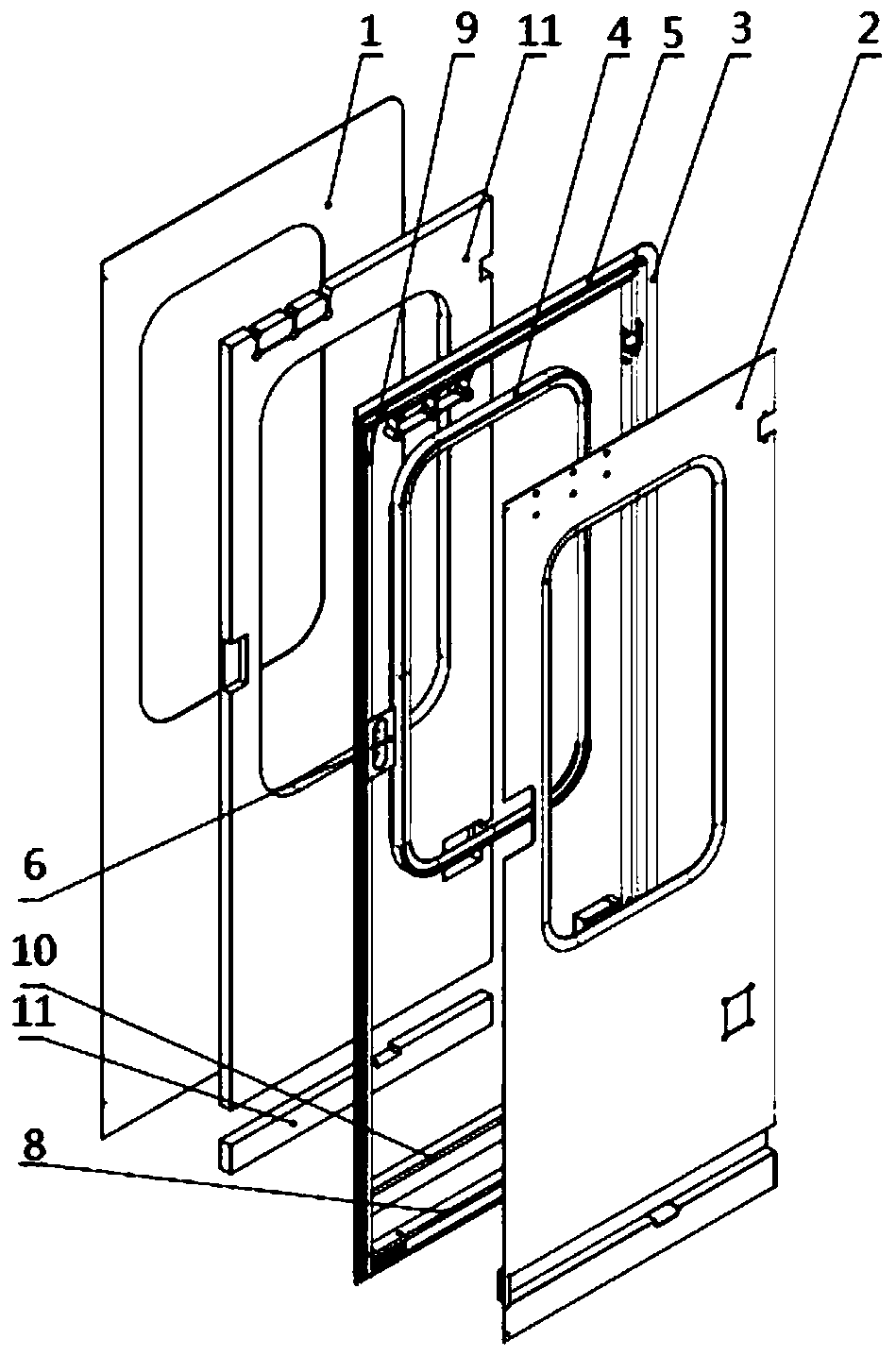

[0015] Such as Figure 1-2 , an urban track door panel of the present invention, comprising a skin, an aluminum honeycomb 11 and a profile frame, the skin includes an outer skin 1 and an inner skin 2, the outer skin 1 is arranged on the outside of the door panel, and the inner skin 2 is arranged on the inside of the door panel, The profile frame includes an upper rail 4, a lower rail 8, a front rail 7 and a rear rail 3. The upper rail 4 is installed on the top of the door panel, the lower rail 8 is installed on the bottom of the door panel and the lower rail 8 is provided with a glide path installation interface, and the upper rail 4 is installed on the lower left side. Installing frame is set, and window frame 5 is arranged on the door panel, and clasp handle 6 is arranged beside window frame 5.

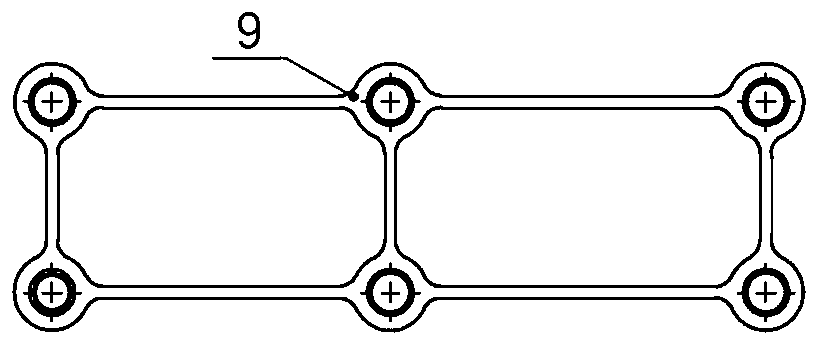

[0016] Such as image 3 , the mounting frame 9 and the upper file 4 are installed independently, ensuring the accuracy of the hole position on the mounting frame and reducing the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com