Focusing component for stage projector lamp

A spotlight and light source component technology, which is applied in the field of stage spotlights, can solve problems such as inaccurate bulb center positioning, affecting accurate focus positioning, and reducing bulb service life, achieving safe and reliable costs, convenient operation, and extended service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to have a further understanding of the present invention, the stage spotlight focusing assembly according to the present invention will be described in detail below in conjunction with the accompanying drawings.

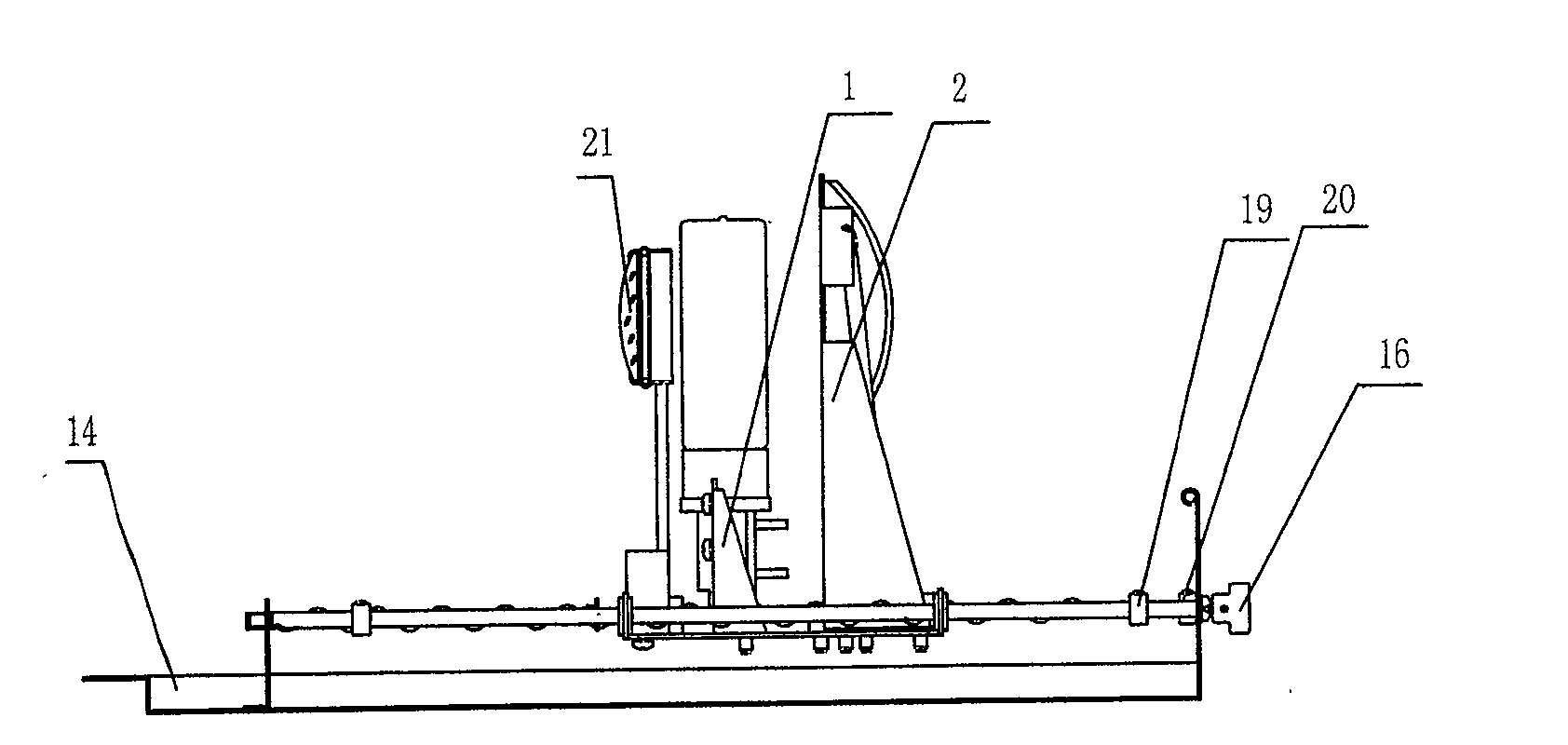

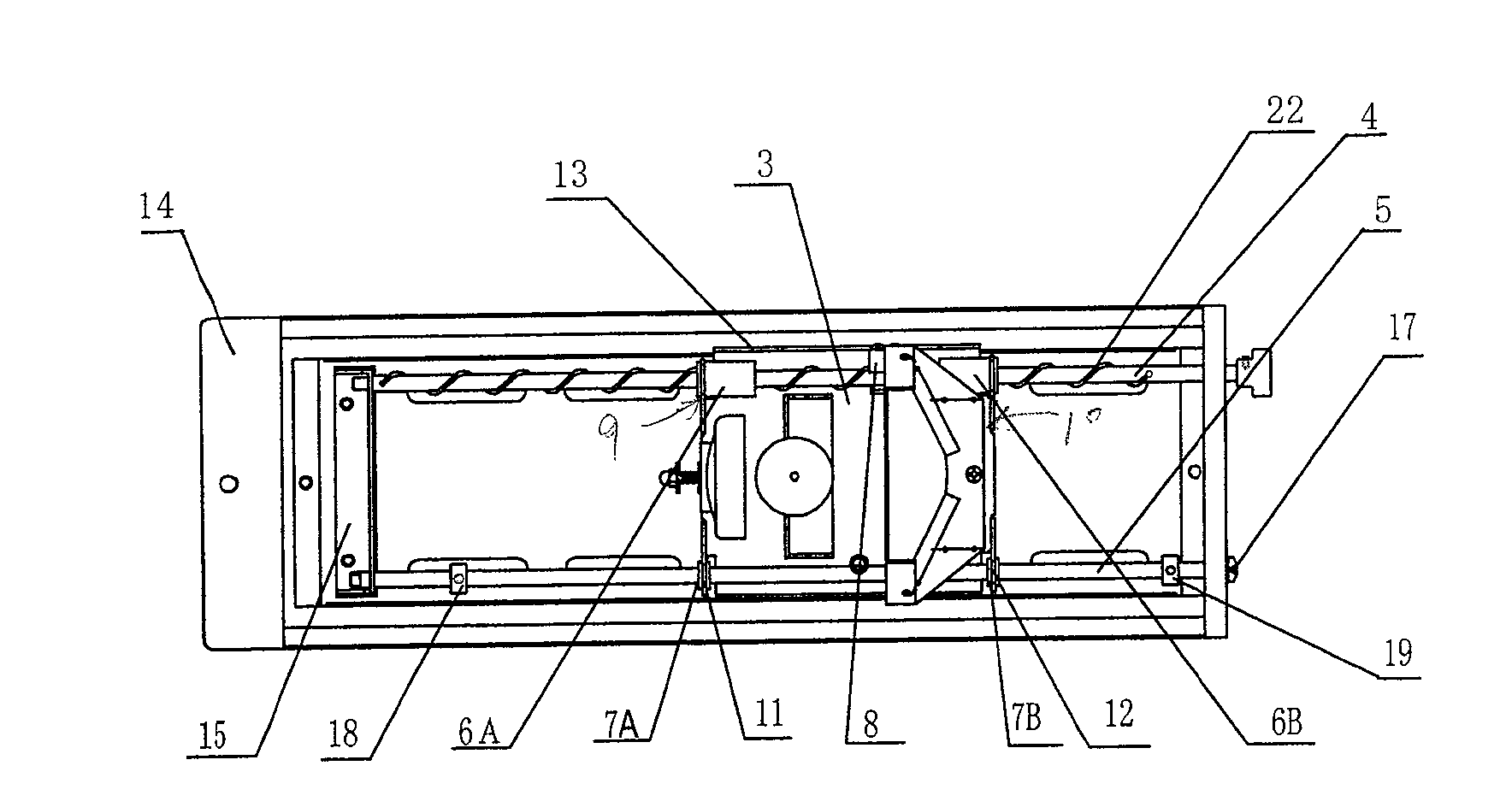

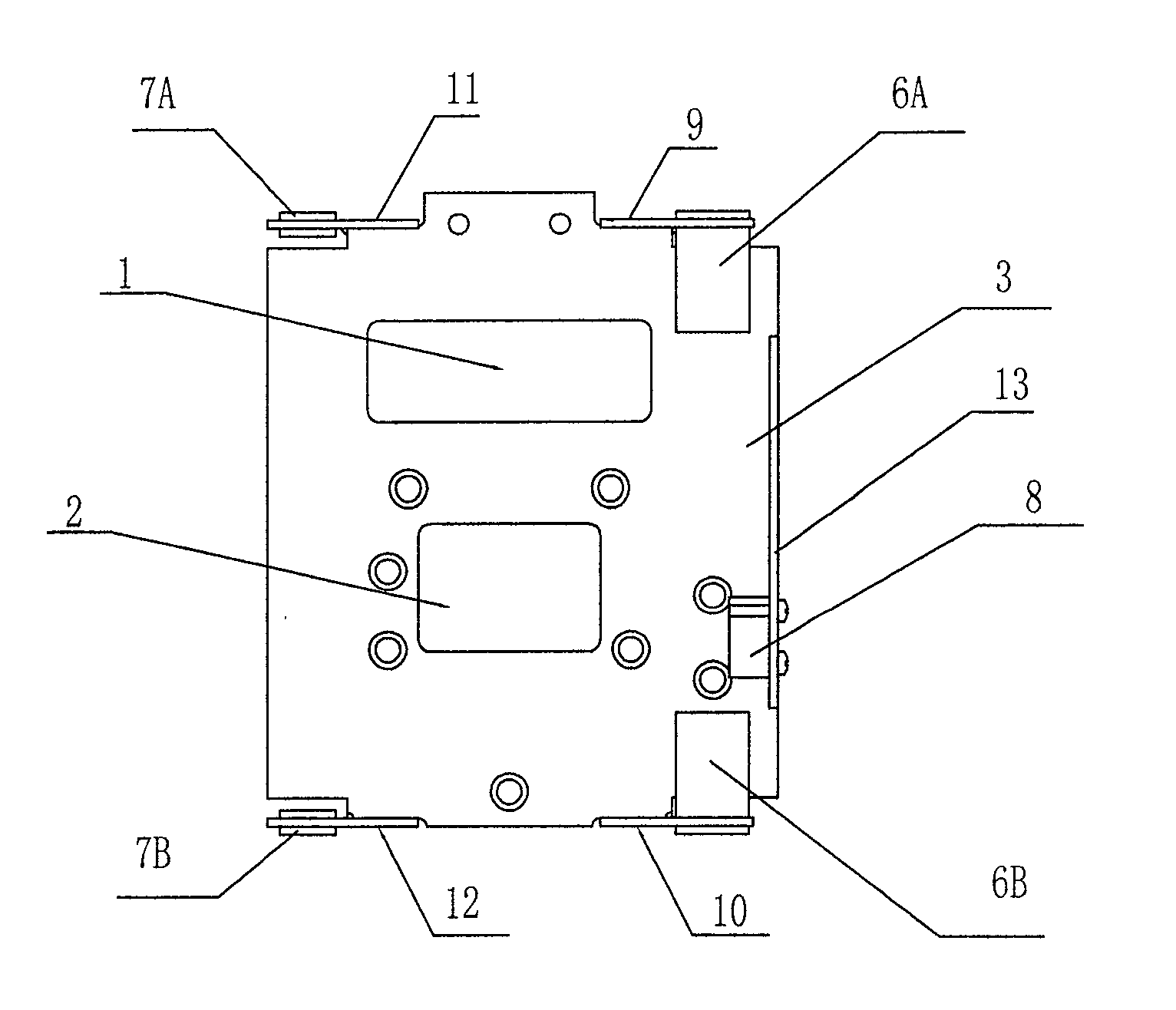

[0025] like Figure 1-Figure 4 Shown is a schematic structural diagram of an embodiment of the present invention. The stage spotlight focusing assembly provided by the present invention includes a light source assembly 1, a reflective bowl assembly 2, a sliding seat plate 3, a screw 4, a sliding rod 5, and two large guide sleeves 6A , 6B, two small guide sleeves 7A, 7B, slide block 8, lower supporting plate 14, support 15. The light source assembly 1 and the reflective bowl assembly 2 are respectively fixed on the slide plate 3 in parallel, the light source assembly 1 is on the left side, and the reflective bowl assembly 2 is on the right side. The left and right edges of the slide plate 3 are respectively provided with two protruding side plates 9, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com