Mfg, method of brown corduroy werve and brown corduroy werve producted by said method

A manufacturing method and technology of corduroy, which is applied in dyeing, textiles, papermaking, textiles, etc., can solve problems such as the inability to weave denim yarn-dyed corduroy, and achieve the effects of elegance, comfort, and export

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

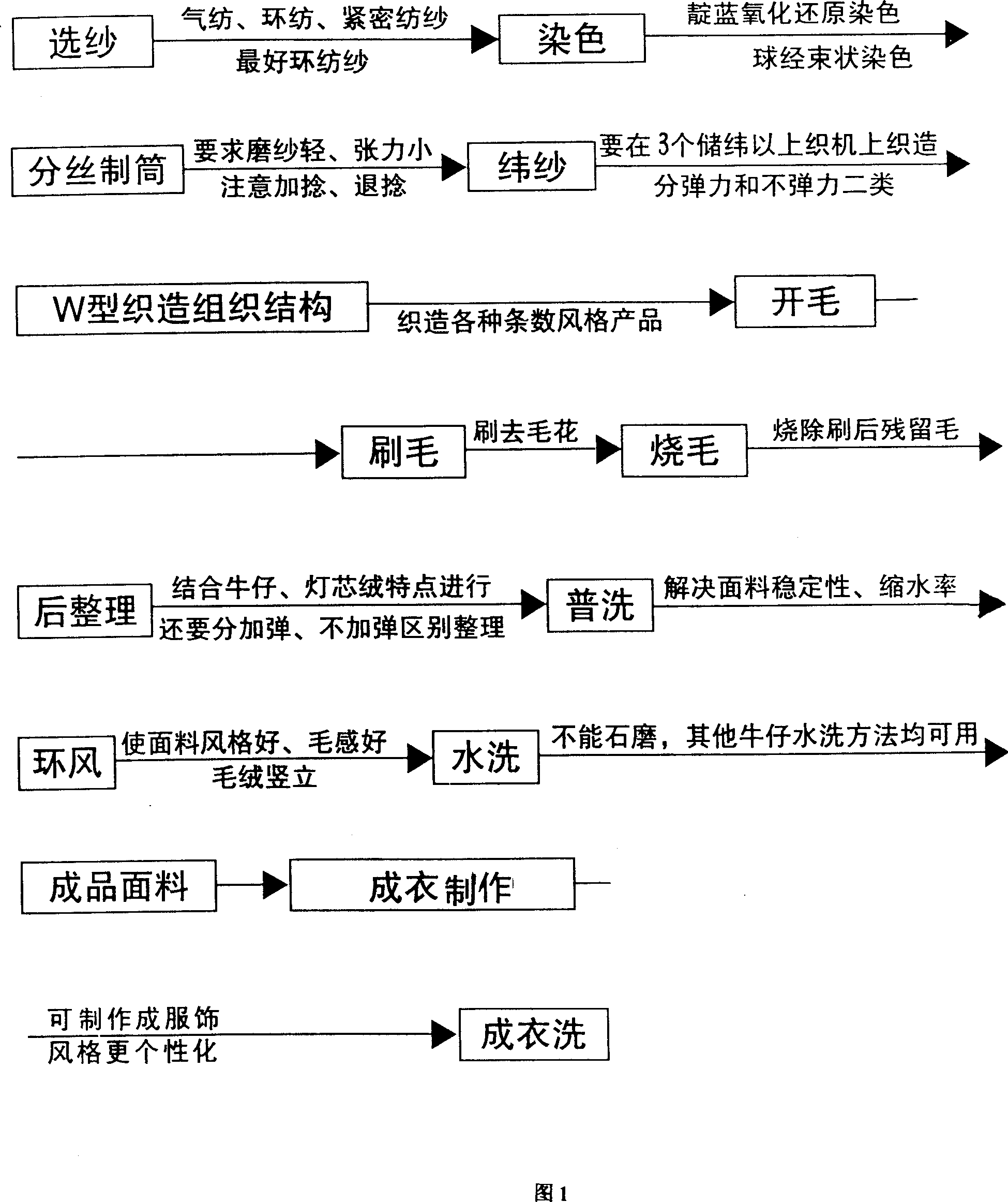

[0010] Referring to Fig. 1, a kind of manufacturing method of denim yarn-dyed corduroy of the present invention comprises yarn selection, dyeing, tube making, weaving, unhairing, brushing, finishing, general washing, water washing, finished product production process, and its improvement point is : also include singeing, ring air, and garment washing processes, on a loom with at least three weft feeders, adopt a W-shaped weaving structure to weave; adopt the denim yarn-dyed corduroy produced by the manufacturing method, by The weft yarn and the warp yarn are woven, the weft yarn is denim yarn, and the warp yarn is common yarn or colored yarn. For weaving, 2-28 strips per inch, or 21-30 imitation velveteen strips per inch, large and small strips, spacer strips, sub-mother strips and other formats can be selected, so that the woven denim yarn-dyed corduroy fabric has simple nostalgia, roughness Bold and unique style.

[0011] The tube-making process adopts a filament tube-makin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com