Low permeating oil layer vertical crack directional perforating crushing method

A technology of directional perforation and vertical fracture, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc. It can solve the problems of high development cost, low natural production capacity, low permeability and so on, so as to avoid the difficult effect of water injection , Improve the seepage capacity and increase the effect of oil drainage area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1. The thickness of sandstone in layer PI7 of Well G155-80 is 1.3m, and the effective thickness is 0.6m.

[0029] 1. Determine the perforation azimuth:

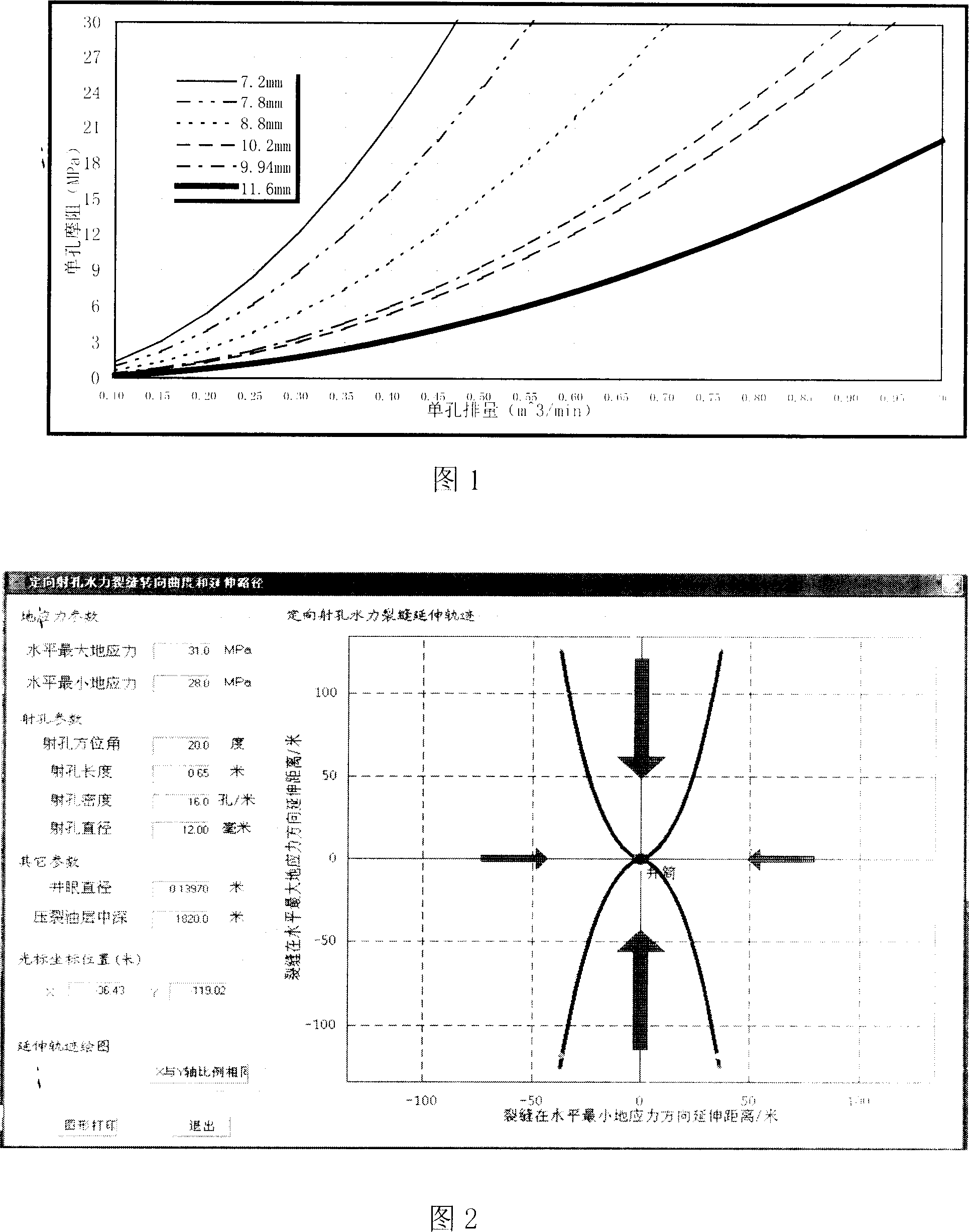

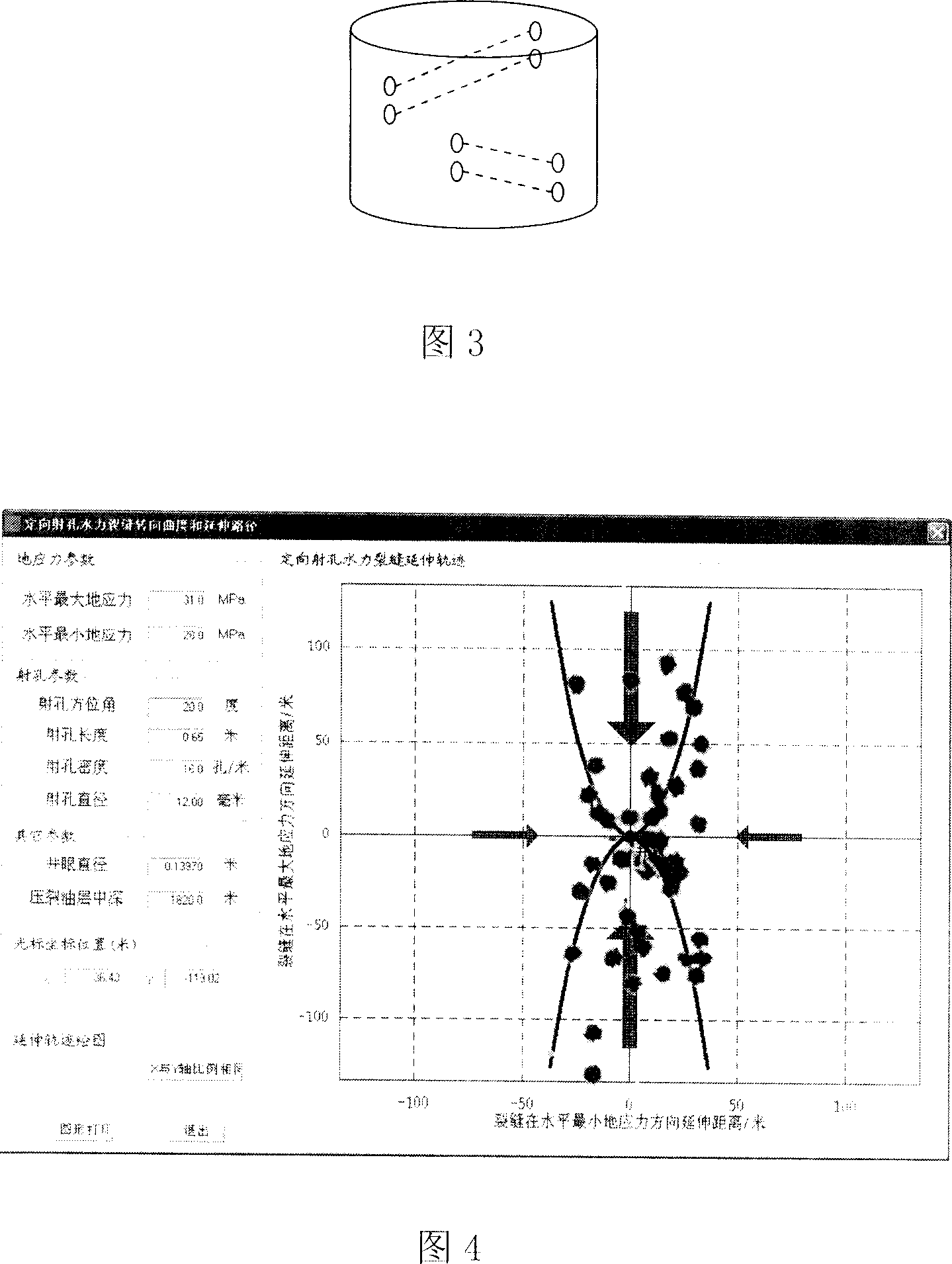

[0030] According to the XMAC logging interpretation results of this block, the direction of the maximum horizontal principal stress is NE80°, the maximum horizontal principal stress is 31MPa, and the minimum horizontal principal stress is 28MPa. Run the "Directional Perforation Hydraulic Fracture Steering Curvature and Extension Path Software", input horizontal maximum stress 31MPa, horizontal minimum stress 28MPa, perforation azimuth angle (10.0, 20.0, 30.0 or 40.0) degrees, perforation length 0.65 m, The perforation density is 16.0 holes / m, the perforation diameter is 12.00 mm, the wellbore diameter is 0.13970 meters, and the depth of the fractured oil layer is 1820 meters. The fracture shape under different perforation azimuths can be obtained. According to the perforation direction, it should be set close t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com