Method and device for rectifying deviation of steel band

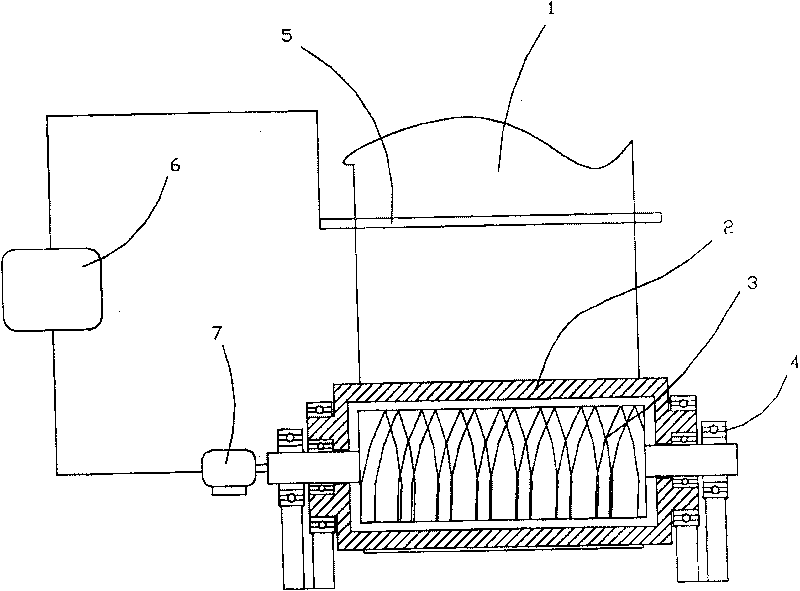

A deviation correction device and strip steel technology, applied in the field of strip deviation correction, can solve problems affecting production efficiency and strip quality, scratches on the surface of the strip steel, high maintenance costs, etc., to improve the deviation correction accuracy and quality, and reduce the space size of the device , Reduce the effect of maintenance and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

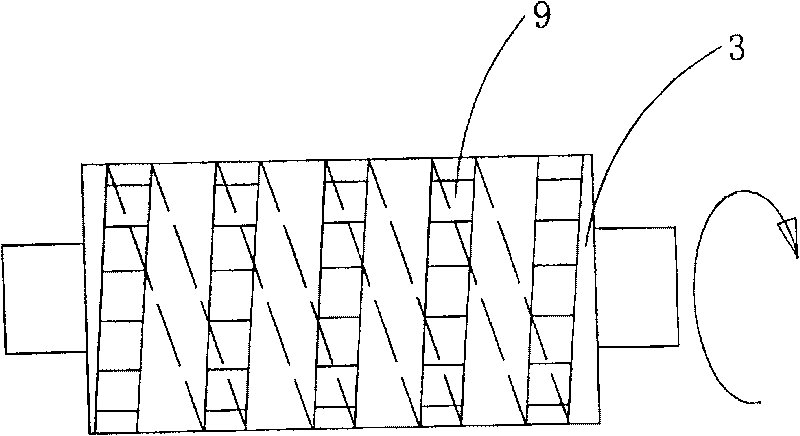

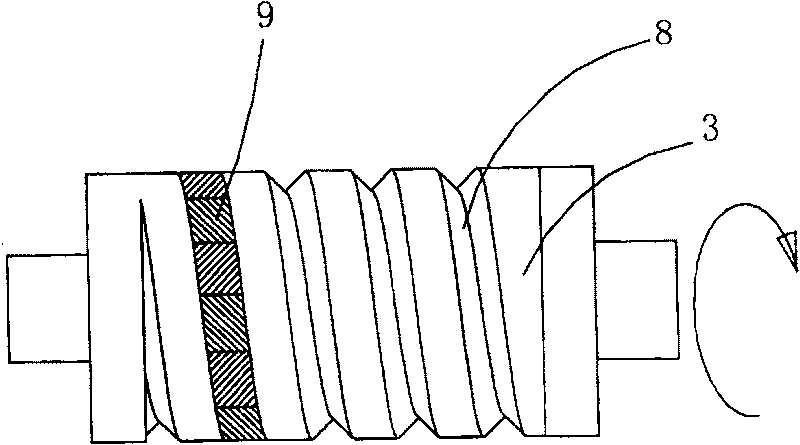

Method used

Image

Examples

Embodiment 1

[0026] see Figure 5 , The invention is applied to the deviation correction of the pickling loop section of cold-rolled silicon steel sheets. Steel strip 1 passes through tension roller 12, spiral magnetic correction roller 13, 15, 17, then passes through turning roller 14 and 16, enters degreasing tank 18, washing tank 19, pickling tank 20, washing tank 21. Among them, the deviation correction rollers 13, 15, 17 correct the deviation of the strip steel 1 at the two ends of the loop, so that the strip steel 1 enters the degreasing tank and the pickling tank centeredly, thereby improving the deviation correction accuracy and improving the degreasing and pickling effects of the strip steel 1 surface. Among the figure: 22 is a hoist, and 23 is a looper tension trolley.

Embodiment 2

[0028] see Figure 6 , the present invention is applied to uncoiling deviation correction. An uncoiler 31 , a spiral magnetic deviation correction roller 32 , and a strip steel offset position sensor 33 . The deviation correction roller 32 guarantees that the uncoiled strip is centered and moves to the next procedure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com