Equipment for acid washing barrels

A pickling device and barrel acid technology, which is applied in the field of barrel pickling devices, can solve problems such as low work efficiency, high labor intensity of workers, and difficulty in ensuring quality, and achieve the effects of saving motor costs, reducing labor intensity, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

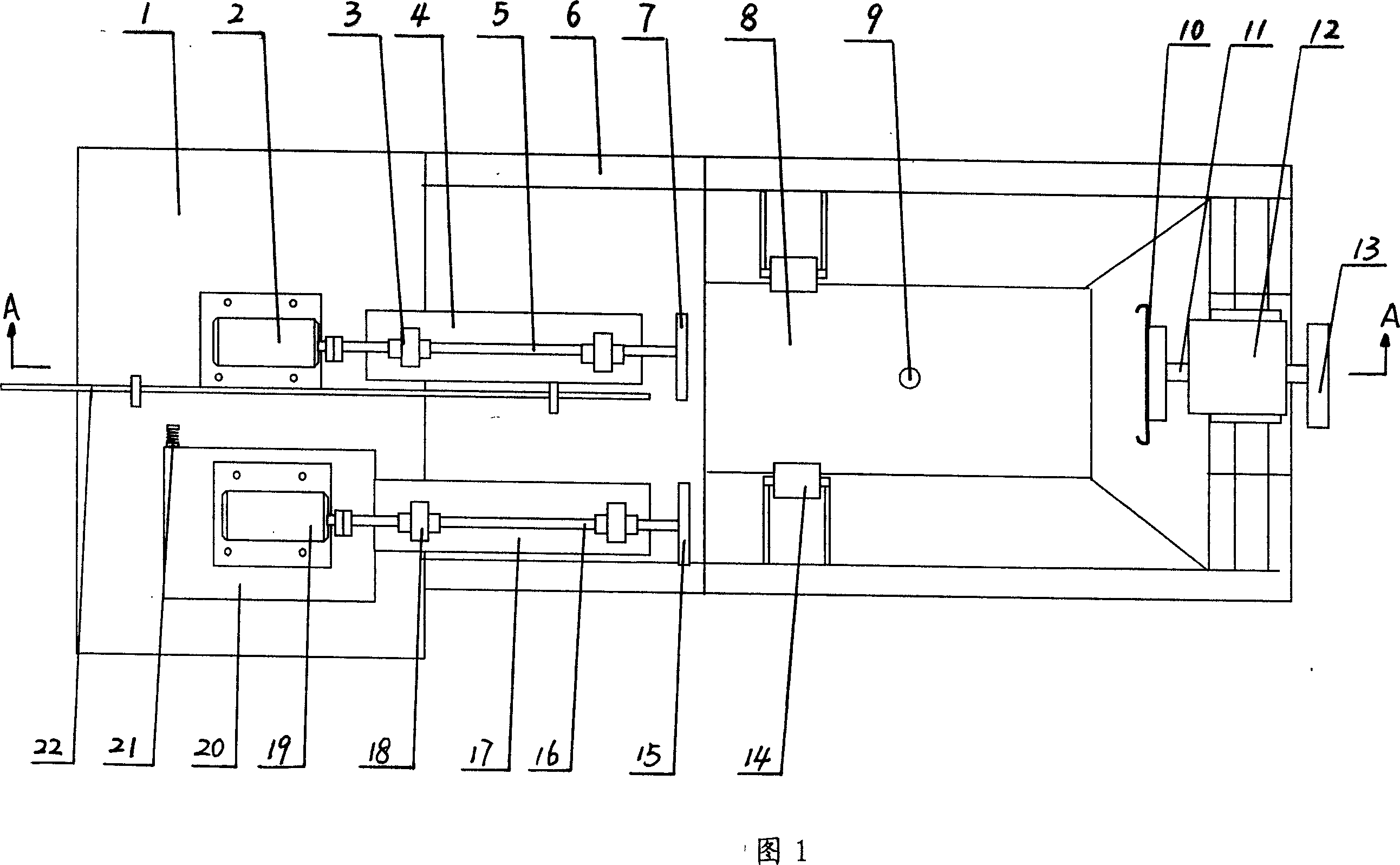

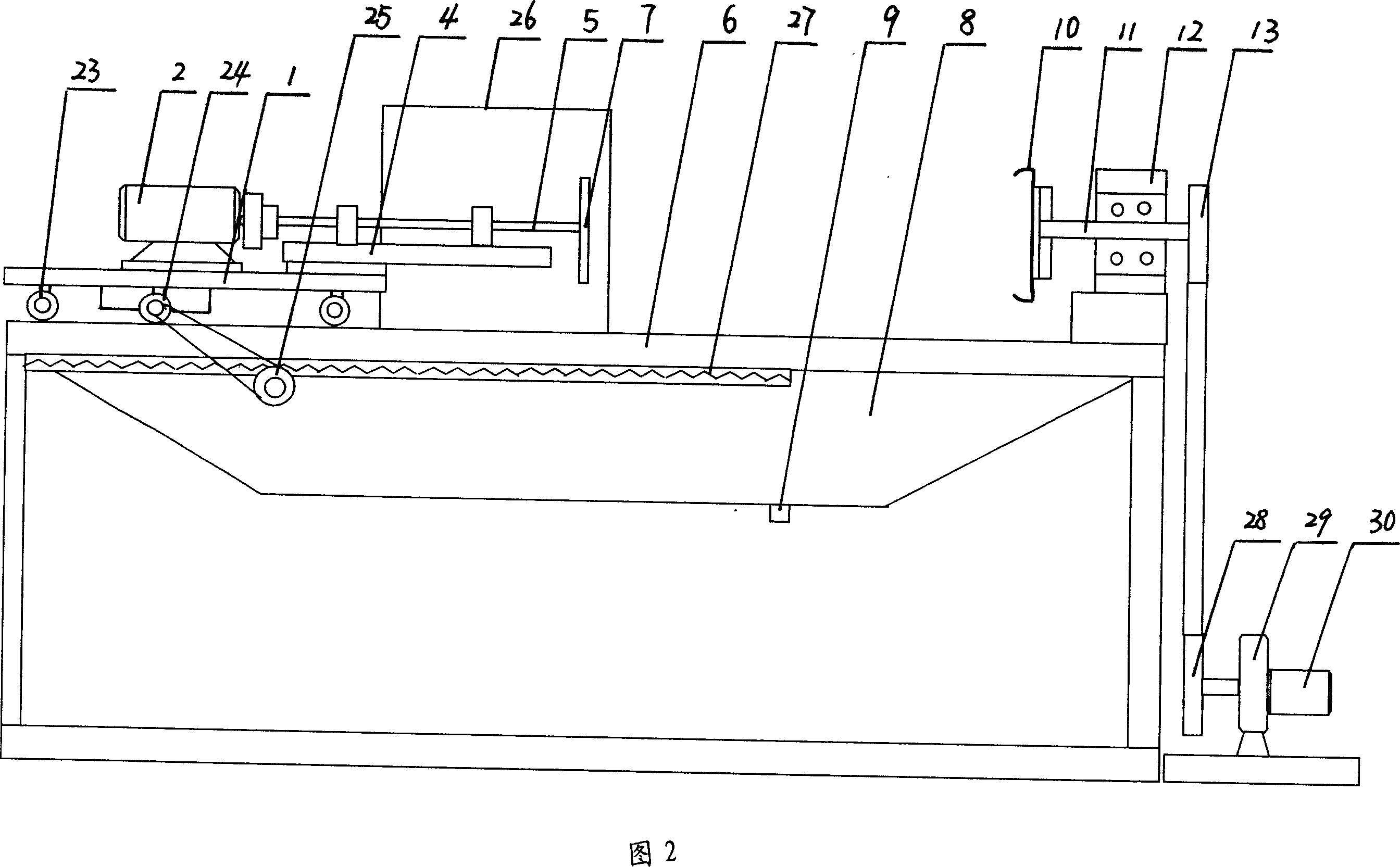

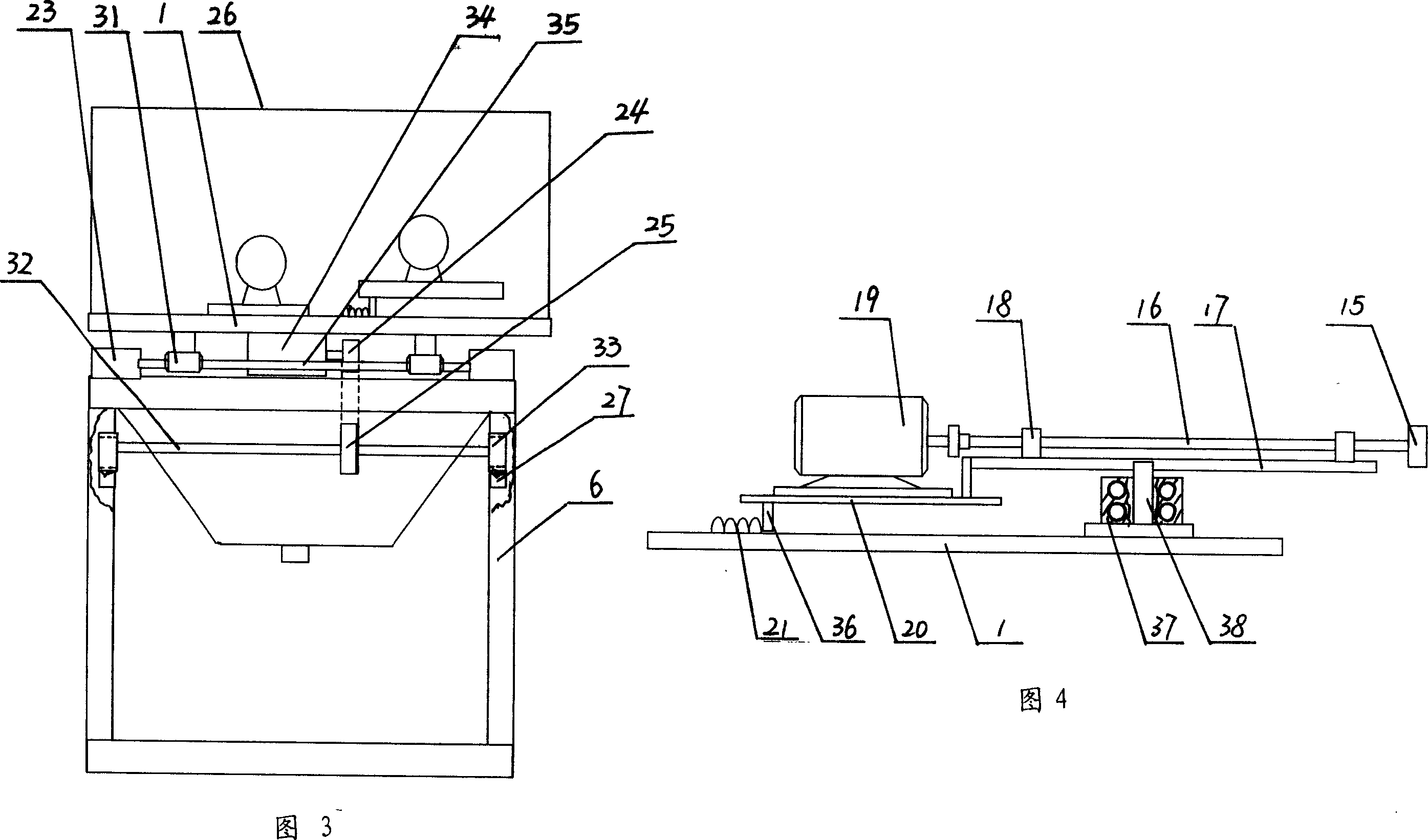

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] The schematic diagram of bucket pickling device of the present invention is shown in Figure 1, Figure 2 and Figure 3, comprises main frame 6, tackle and bucket rotating mechanism, one end of main frame is provided with barrel rotating mechanism, and the other end is provided with tackle. An inner wall pickling mechanism is fixed on the pulley. Tackle comprises tackle supporting plate 1, is connected with traveling shaft 35 by axle frame 31 under supporting board, and the two ends of traveling shaft are connected with traveling wheel 23 respectively, and traveling wheel places on the main frame. A forward and backward motor 34 is fixed on the tackle pallet 1 . There are two ways for the advancing and retreating motor to drive the block motion. One is that the advancing and retreating motor 34 is connected with the traveling shaft throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com