Heat radiation shell and its producing method

A technology for heat dissipation shells and manufacturing methods, which is applied in the fields of electrical equipment shells/cabinets/drawers, cooling/ventilation/heating transformation, instrument cooling, etc., which can solve poor heat dissipation effects, anisotropic heat dissipation properties, and affect the heat dissipation effect of shells and other issues, to achieve the effects of saving production costs, improving heat dissipation properties, and reducing plating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

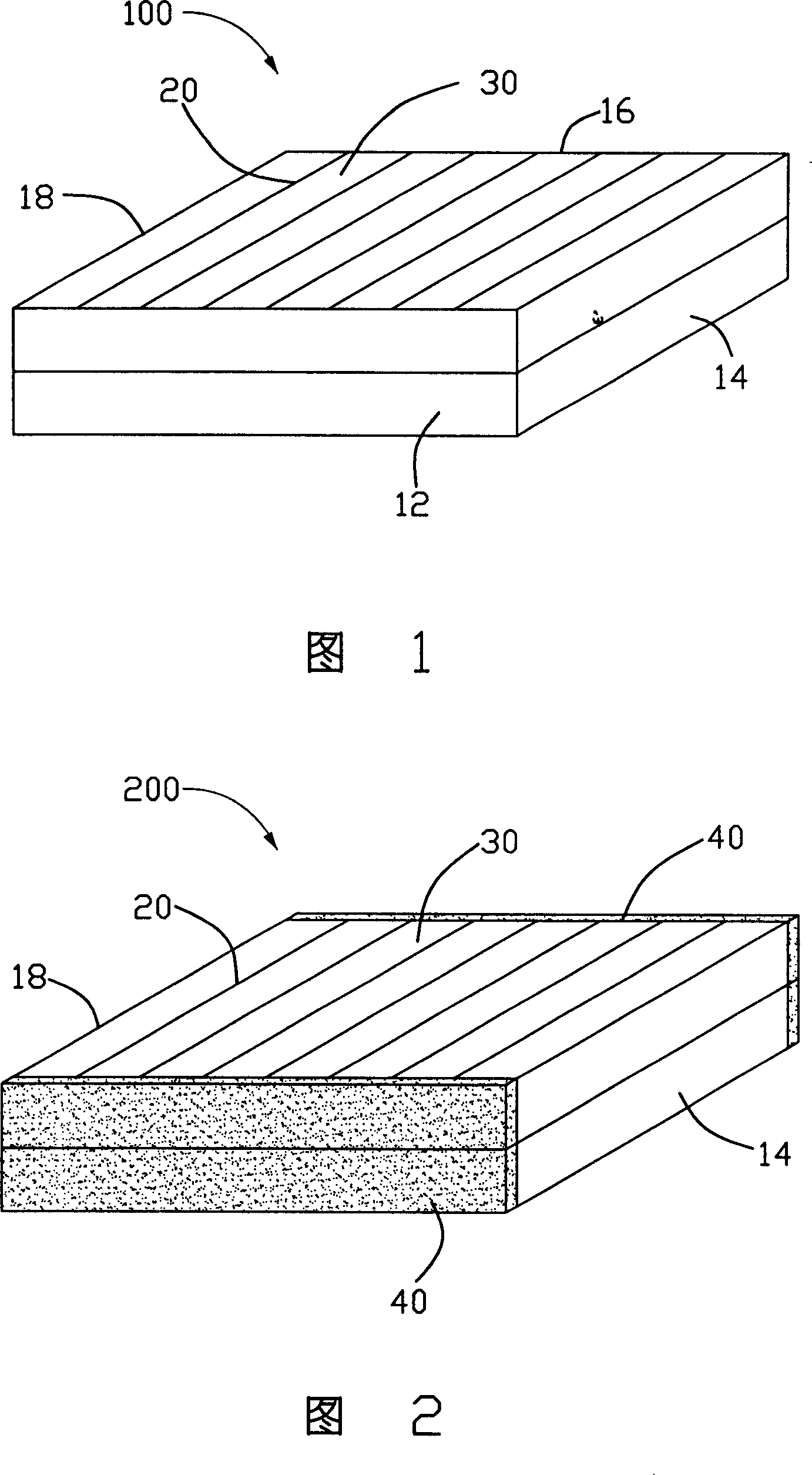

[0013] The following will take a notebook computer case as an example to describe a heat dissipation case and a manufacturing method thereof.

[0014] Please refer to Fig. 1, which is a notebook computer casing 100 provided by this embodiment. Fig. 1 shows that the notebook computer casing 100 is in a closed state, which includes a first side 12 and a third side 16 opposite to each other, and a side opposite to the third side 16. The second side 14 and a fourth side 18 .

[0015] The notebook computer case 100 is made of fiber polymer composite material, and the fiber polymer composite material is a composite material of fiber 20 and polymer resin material 30 . The polymer resin material 30 may be epoxy resin, unsaturated polyester, vinyl resin or phenolic resin and the like. The fibers 20 can be carbon fibers, glass fibers or metal fibers, etc., and the fibers 20 are arranged in parallel along the same direction. This embodiment is a carbon fiber epoxy resin composite mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com