Housing, gearbox and gearbox assembly

A transmission device and housing technology, applied in transmission devices, transmission parts, gear transmissions, etc., can solve the problems of high manufacturing costs and component costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention is now described in detail with the aid of the accompanying drawings:

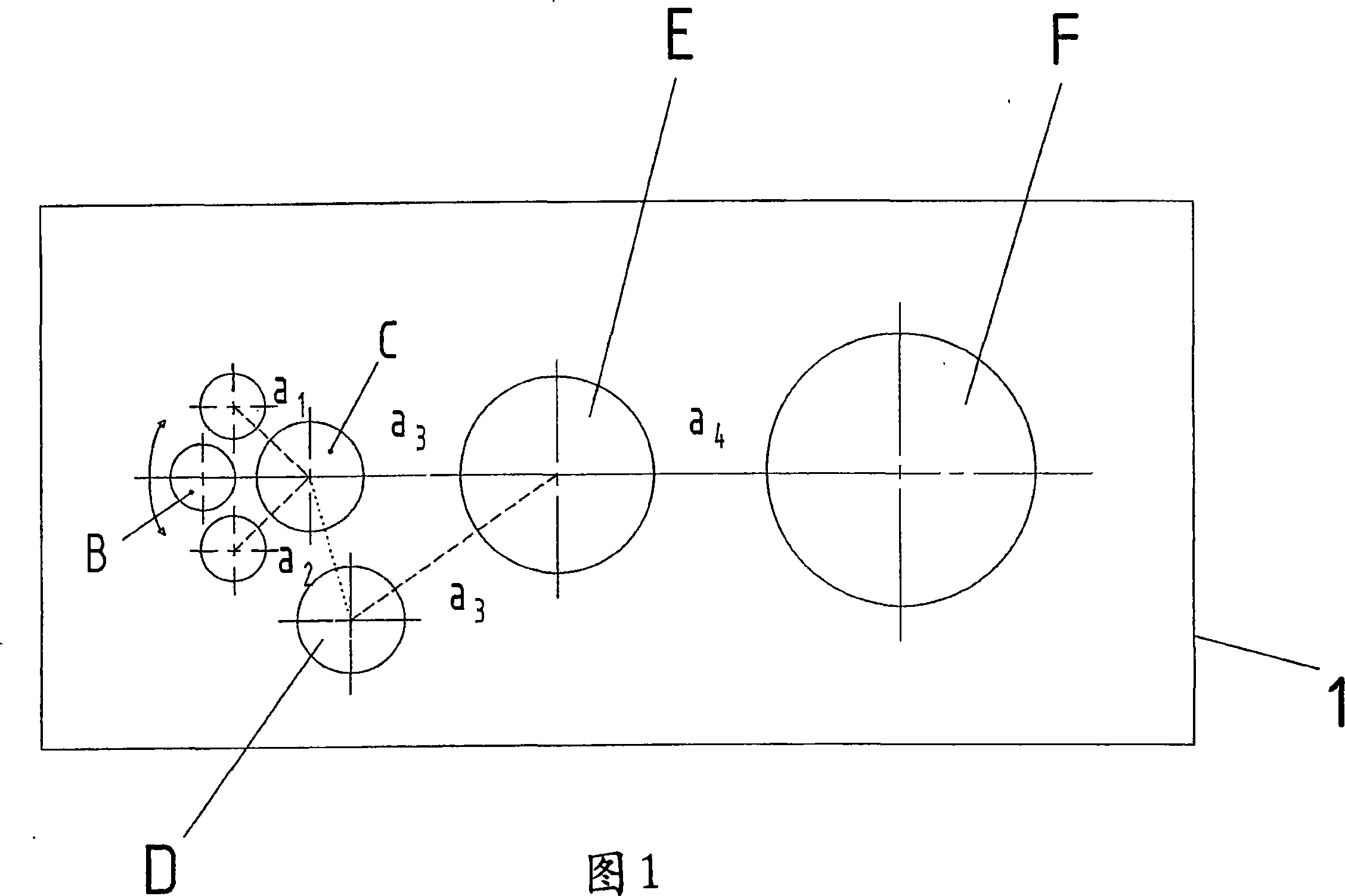

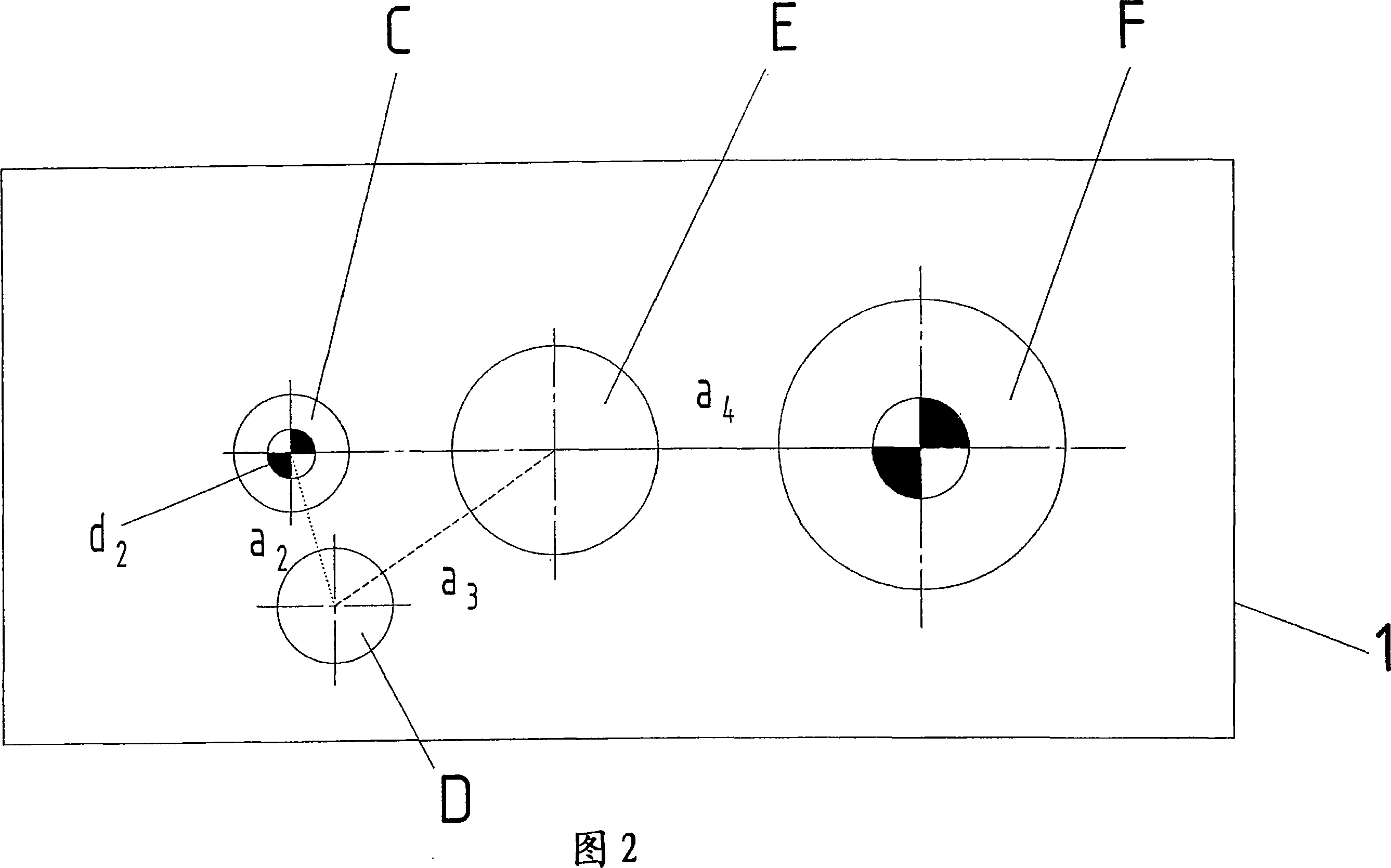

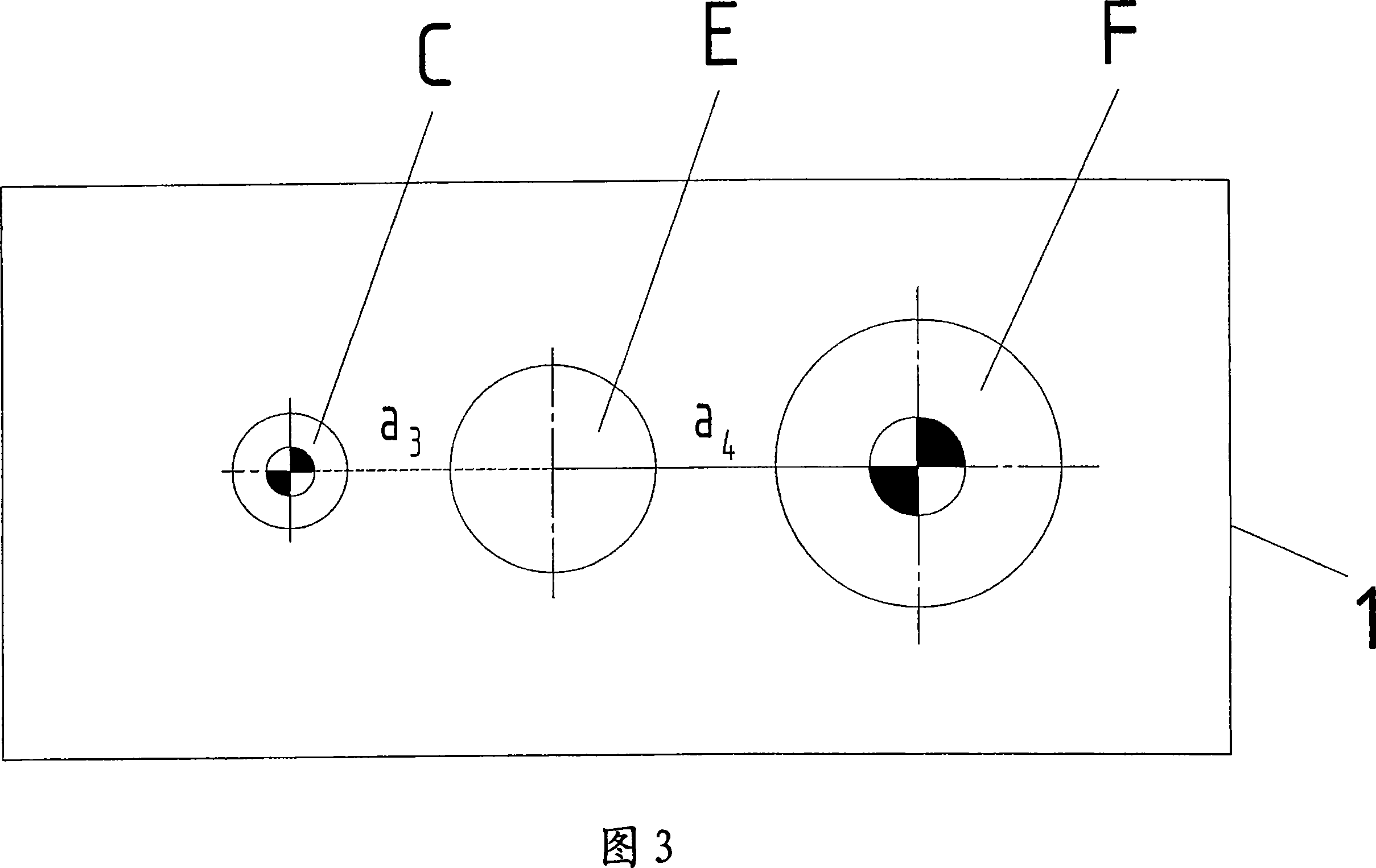

[0048] FIG. 1 schematically shows a side view of the housing of the transmission series according to the invention. The bores B, C, D, E, F are arranged in the region of the housing which forms a thickening of the housing wall so that a bearing point can be formed. By leaving the region of the hole in the housing wall free, material can be saved when casting the housing. In this case, only convenient and fast subsequent processing can be carried out.

[0049] For producing the variants of the transmission series, both all bores and only some of the bores can be used for supporting the shaft. Unused holes are hermetically closed with closure elements. End caps or the like are suitable as closure elements.

[0050] In other embodiments of the present invention, recessed parts, such as knock-down parts or other thinned parts of the housing wall, may also be provided. In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com