Rubber wheel driven high speed train and line

A technology for high-speed trains and rubber wheels, which is applied in the field of trains and vehicles, can solve the problems of increasing the radius of the curve, increasing the cost and loss of the line, and reducing the safety, so as to reduce the radius of the curve, reduce the cost of the line, and reduce noise pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

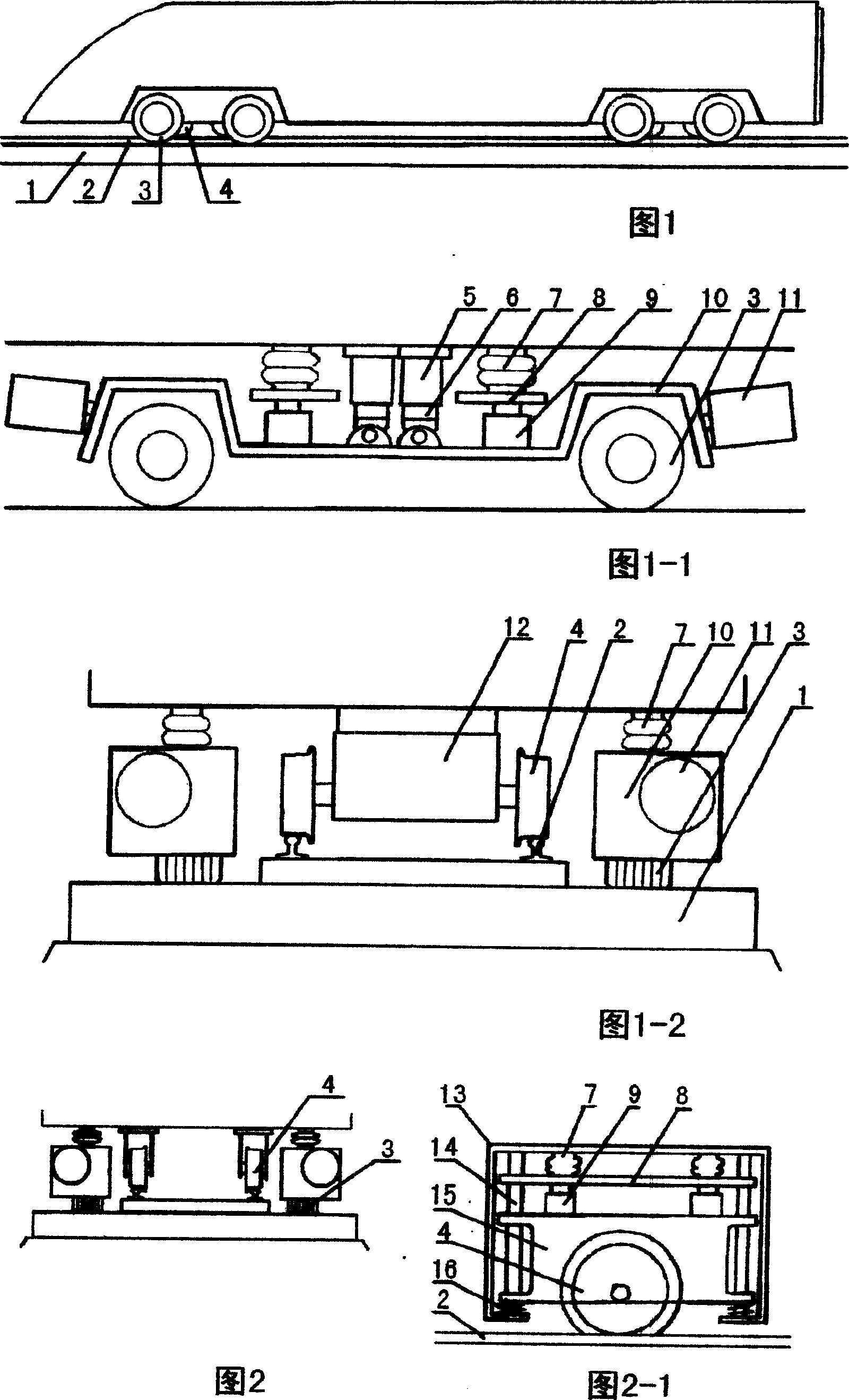

[0020] As shown in Fig. 1, the train with rubber driving wheels 3 installed under the vehicle runs on the line where the road surface 1 is laid on both sides of the rail 2, the steel wheels 4 run on the rails, and the rubber driving wheels 3 run on the road on both sides of the rails Drive the vehicle forward.

[0021] As shown in Fig. 1-1, the wheel frame 10 equipped with the rubber drive wheel 3 is installed under the two sides of the train in a non-rotatable manner through the rocker 6 and the rod sleeve 5. Shock air spring 7 and hydraulic cylinder 9, while rubber drive wheel 3 is driven by motor 11. In application, increase the pressure of the hydraulic cylinder 9, and the hydraulic cylinder presses the train upward through its upper support plate 8 and the air spring, thereby increasing the weight of the train carried by the rubber driving wheel 3, thereby increasing the driving friction pressure between the rubber driving wheel and the road surface . When the pressure ...

Embodiment 2

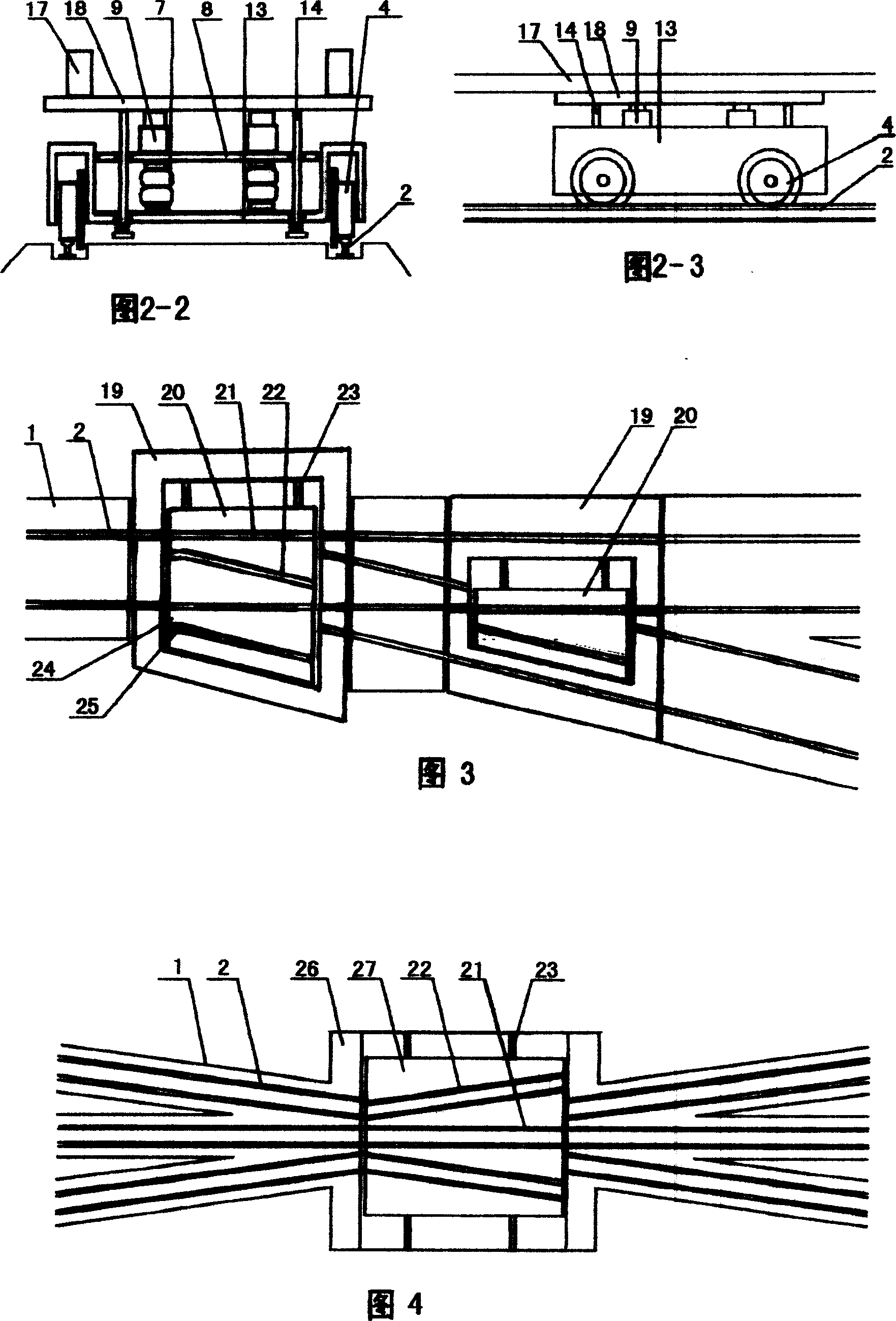

[0030] As shown in Fig. 3, two turnout sleepers 19 in the line are a group of translational turnouts, the straight rail and the branch rail on the ram 20, and the straight transition rail 21 and the branch transition rail 22 are provided with rubber wheels to pass through. The notch interval is 24. The translational turnout utilizes the ram 20 that can move laterally in the chute of the turnout sleeper 19, and the straight transition rail 21 and the fork transition rail 22 on the ram and the road surface for rubber wheels to move laterally in the straight line and the branch line, thereby realizing Switching of straight and branch roads. In the application, the ram 20 in the chute of the two turnout sleepers 19 in the line is simultaneously moved by the electric device through the screw rod or the hydraulic device to complete the line conversion. Since there are notches between adjacent straight rails and branch rails or straight transition rails and branch transition rails i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com