Highly effective anaerobic bioreacto

An anaerobic biological and reactor technology, applied in anaerobic digestion treatment and other directions, can solve the problems of difficult to further improve the treatment efficiency and effluent quality, difficult operation control, increase power consumption and other problems, and achieve good anaerobic biological treatment performance, Enhanced sludge sedimentation effect and reduced surface hydraulic load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

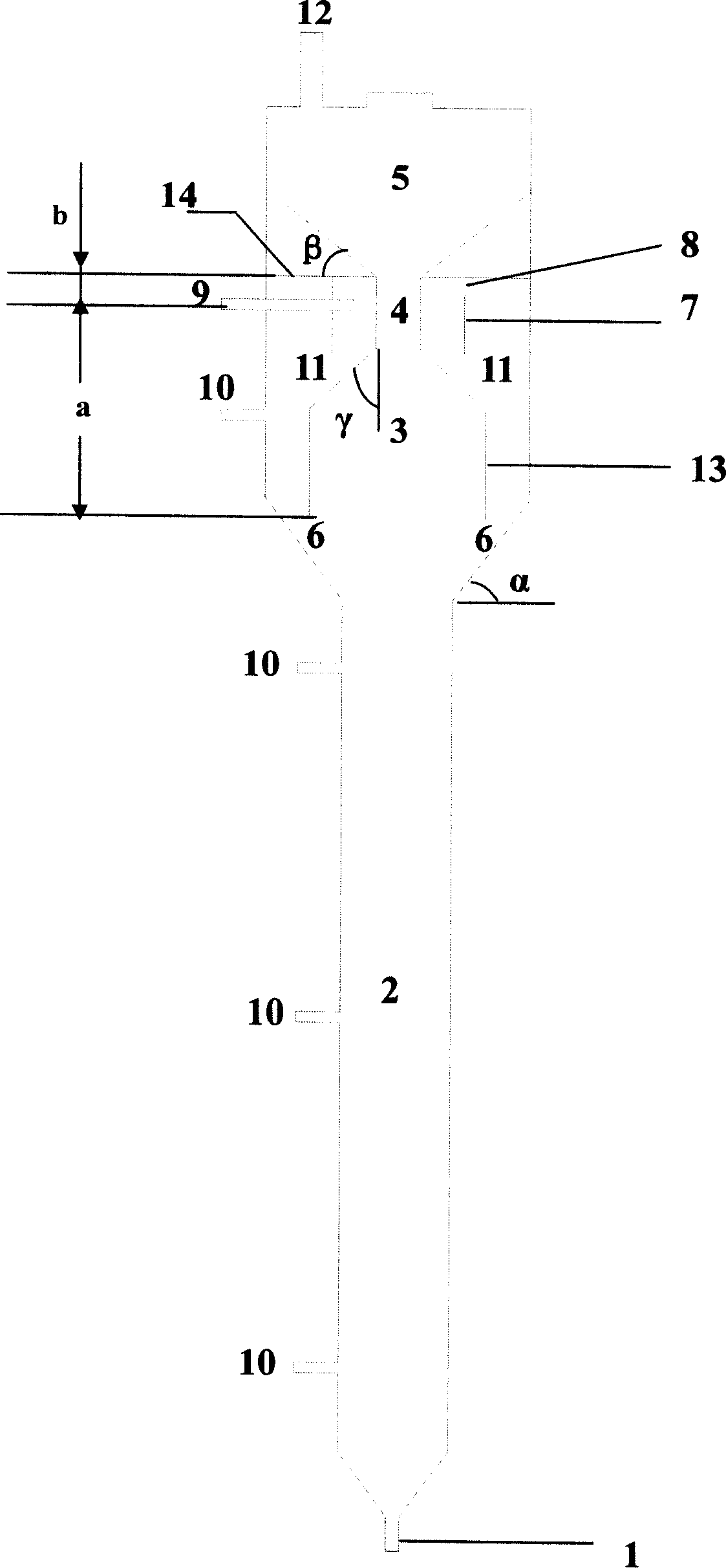

[0010] As shown in the attached figure, the anaerobic bioreactor has a reactor body, and a water inlet pipe 1 and an upflow reaction chamber 2 are arranged at the lower end of the reactor body. The cylinders are connected, and the outer cylinder of the sedimentation chamber 11 is provided with a three-phase separator I chamber 3 and a mud gas riser 4. The mud gas riser 4 is connected with a three-phase separator II chamber 5 at the bottom of the three-phase separator II chamber 5. Expander, the upper part of the three-phase separator I chamber 3 is a reducer, the lower part of the three-phase separator I chamber 3 is a gas collection hood 13, and a settling sewage is arranged between the cylindrical gas collection hood and the outer cylindrical expander. The mud return joint 6 and the mud gas riser 4 are connected to the outer cylinder through the horizontal support plate 14, the water deflection baffle 7 is connected under the horizontal support plate 14, and the mud gas riser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com