Automatic control water-saving energy-saving sterilization machine

A sterilizer, a new type of technology, is applied in the preparation and heating of alcoholic beverages, which can solve the problems that the control of PU value cannot be realized, and achieve the effect of simple structure, good safety performance, large and uniform flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

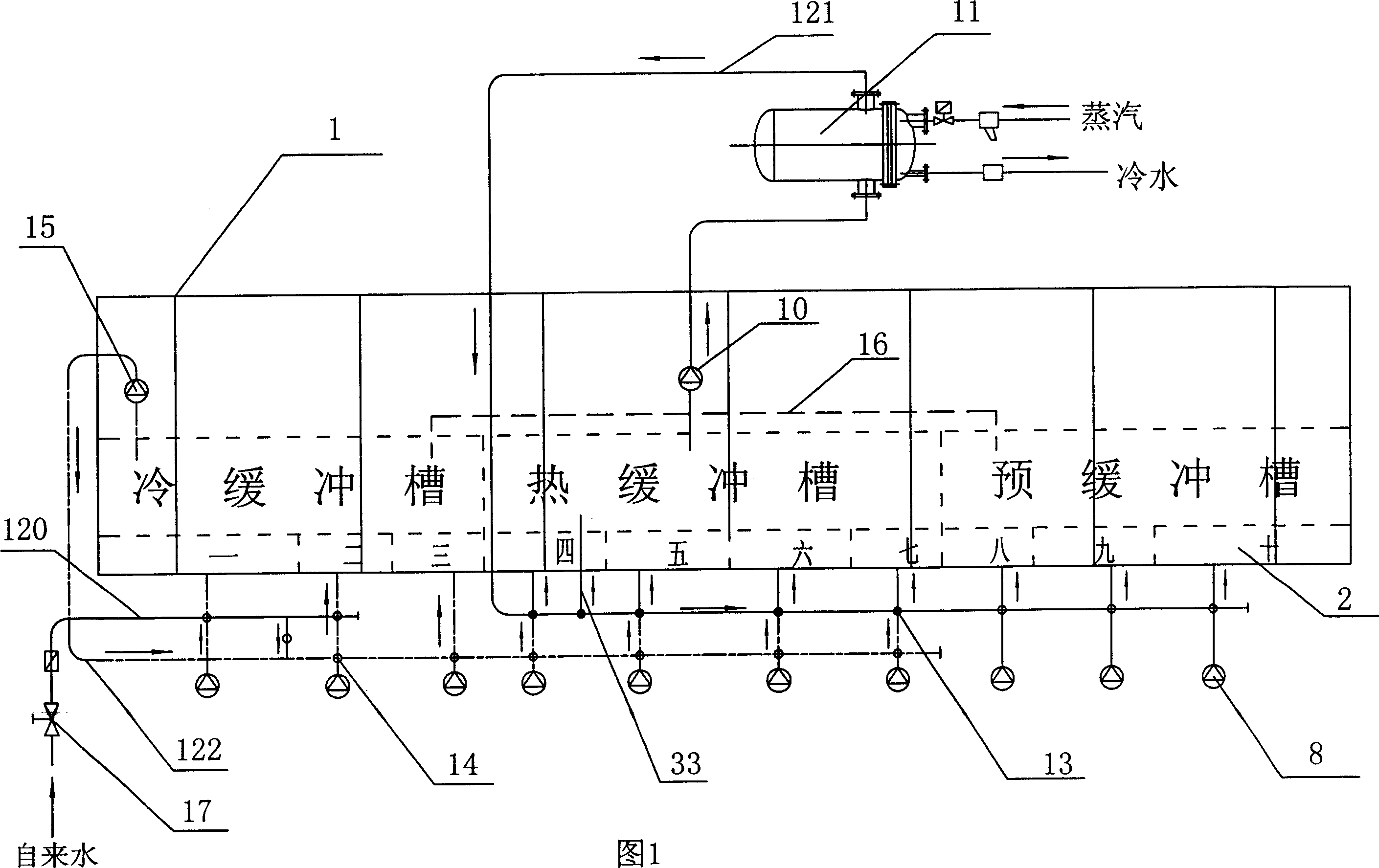

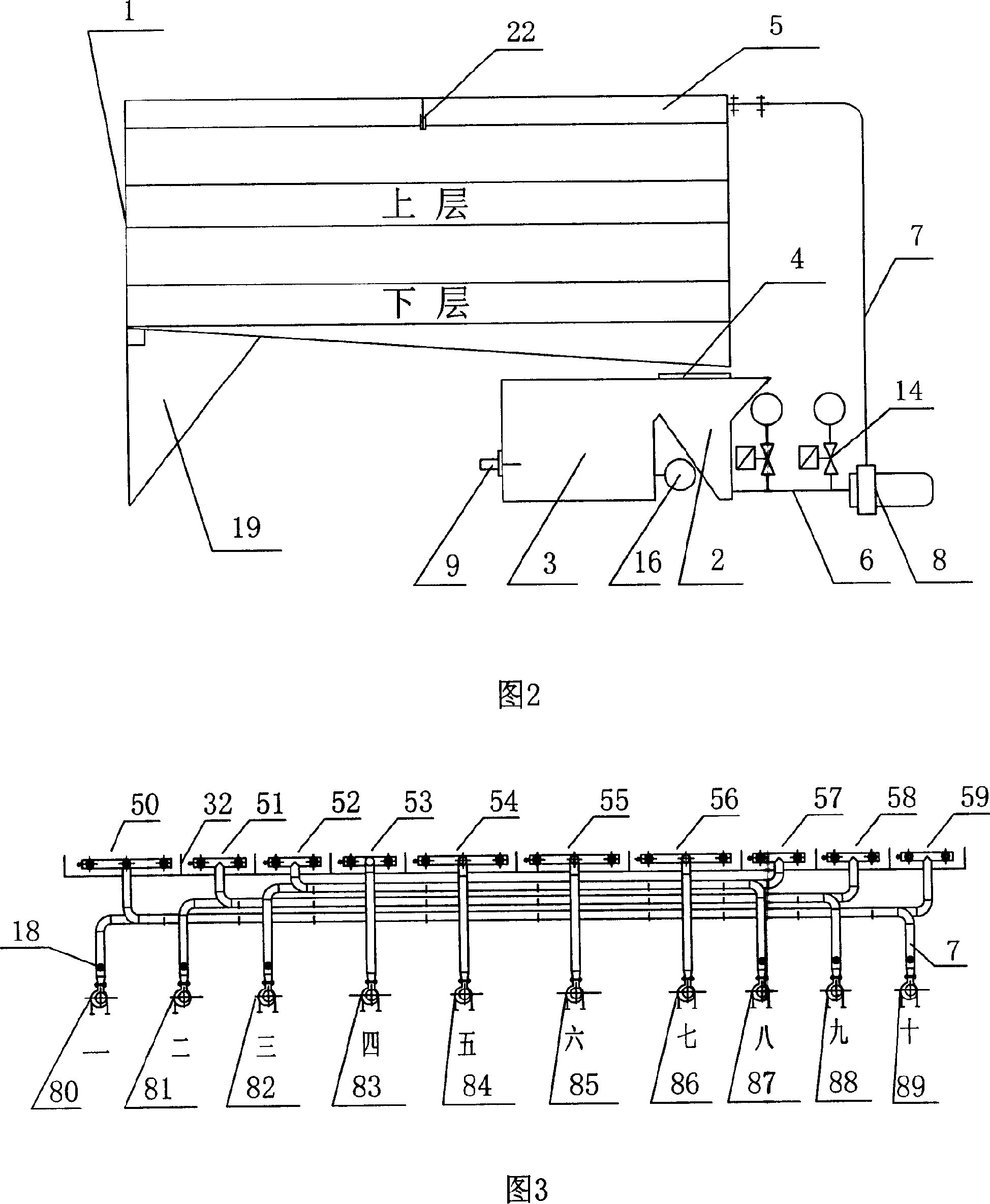

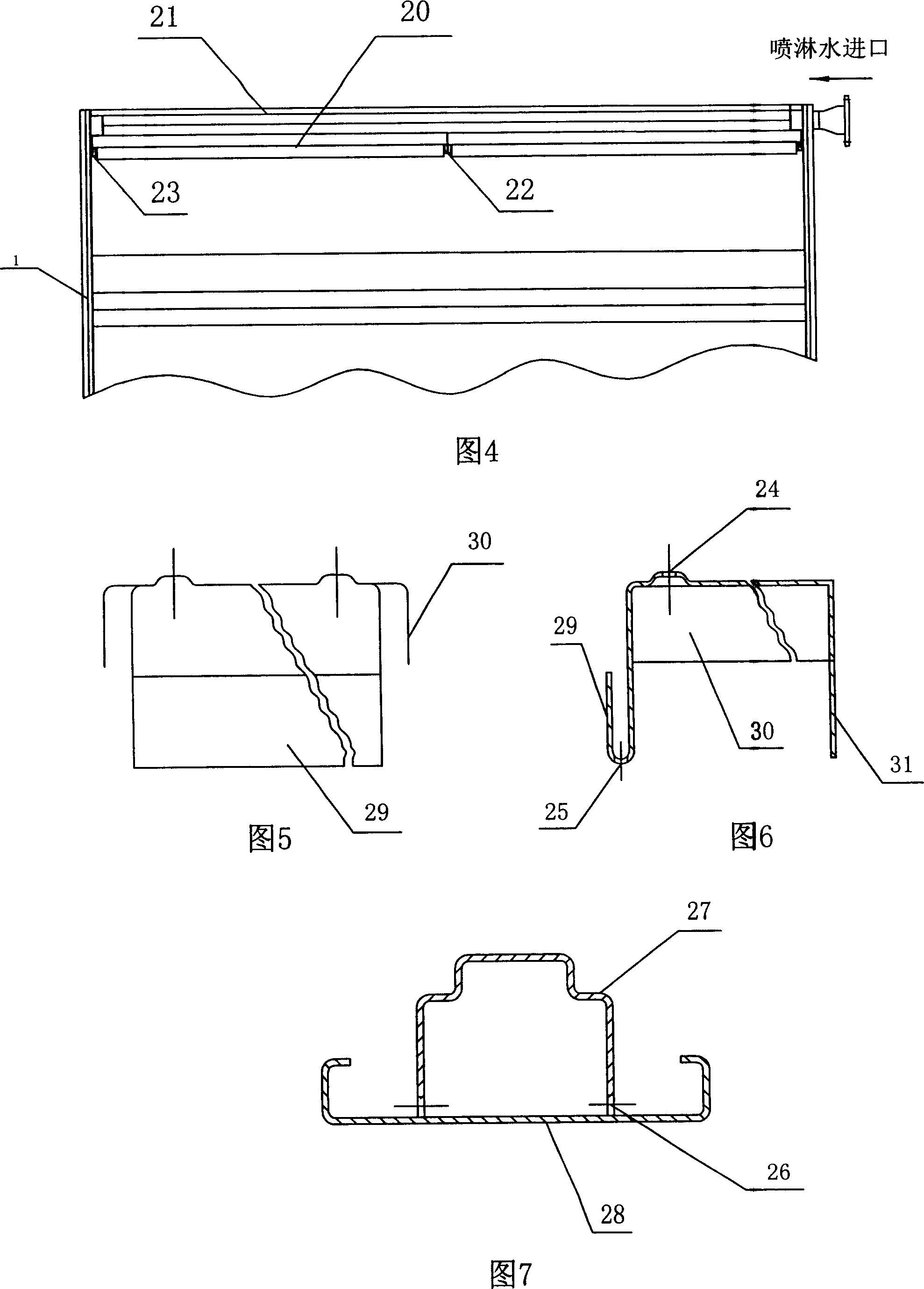

[0031] As shown in Figures 1, 2 and 3, the automatic control water-saving and energy-saving sterilizer of the present invention has main components including a frame 1, a water tank, a water supply system, a chain network support and a transmission system (not shown in the figure). The water tank is divided into a small water tank 2 and a buffer tank 3. There are ten small water tanks 2 corresponding to ten temperature zones, and a decontamination conveying mesh belt 4 is set at the upper part of the small water tank 2 to receive spray water. Buffer tank 3 is divided into three parts: hot buffer tank, cold buffer tank and pre-buffer tank. The cold buffer tank corresponds to three small water tanks 2 and temperature zones 1, 2 and 3. The pre-buffer tank corresponds to three small water tanks 2 and 8 and 9. 10 temperature zones, the heat buffer tank is an insulated water tank, which corresponds to four small water tanks 2 and four, five, six, seven temperature zones, ten small wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com