Lighting system

A lighting system and lighting beam technology, applied in the field of lighting systems, can solve problems such as damage, bulky projection device, overheating, etc., and achieve the effects of reducing the probability of damage, improving collection efficiency, and increasing intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

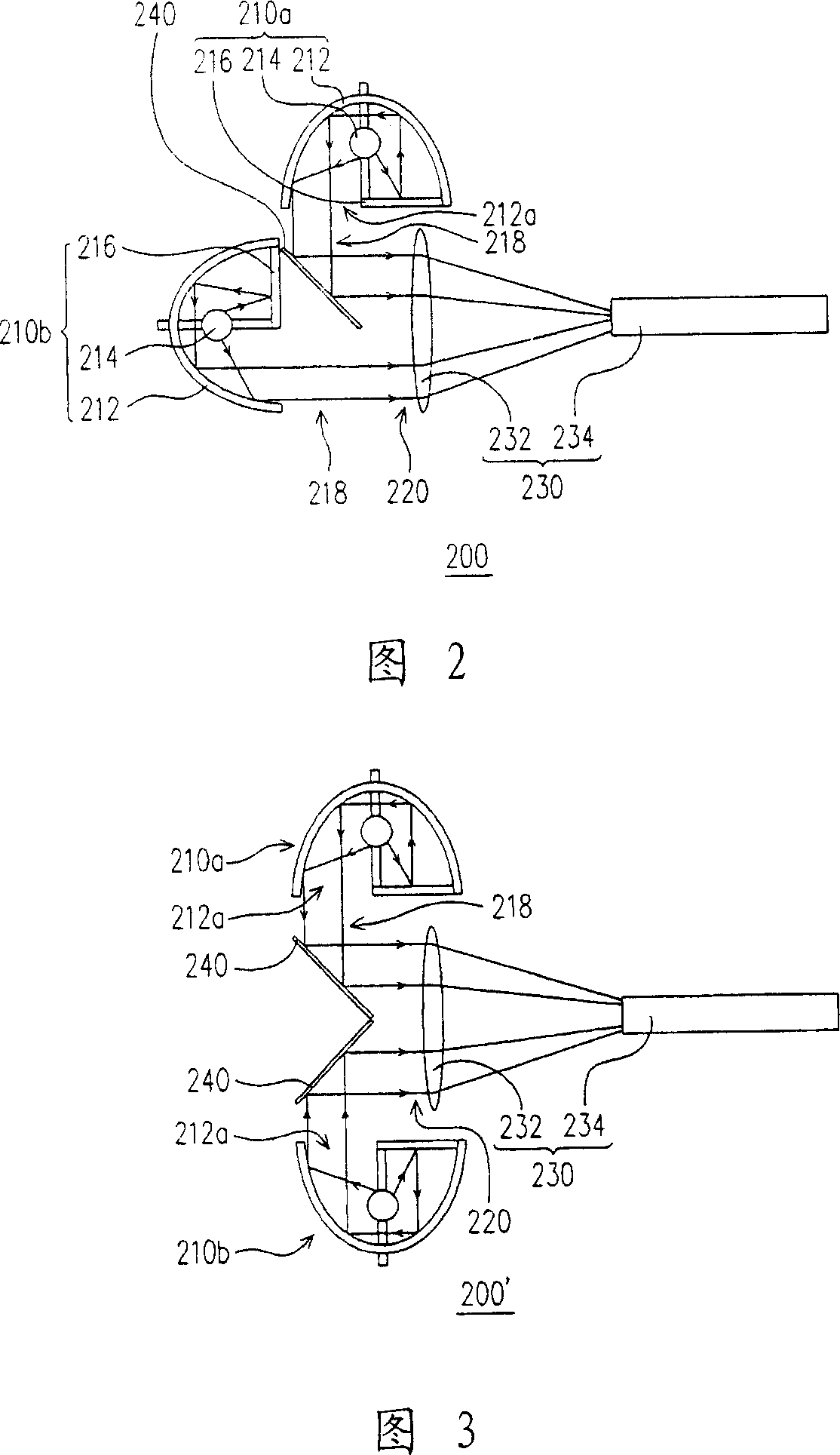

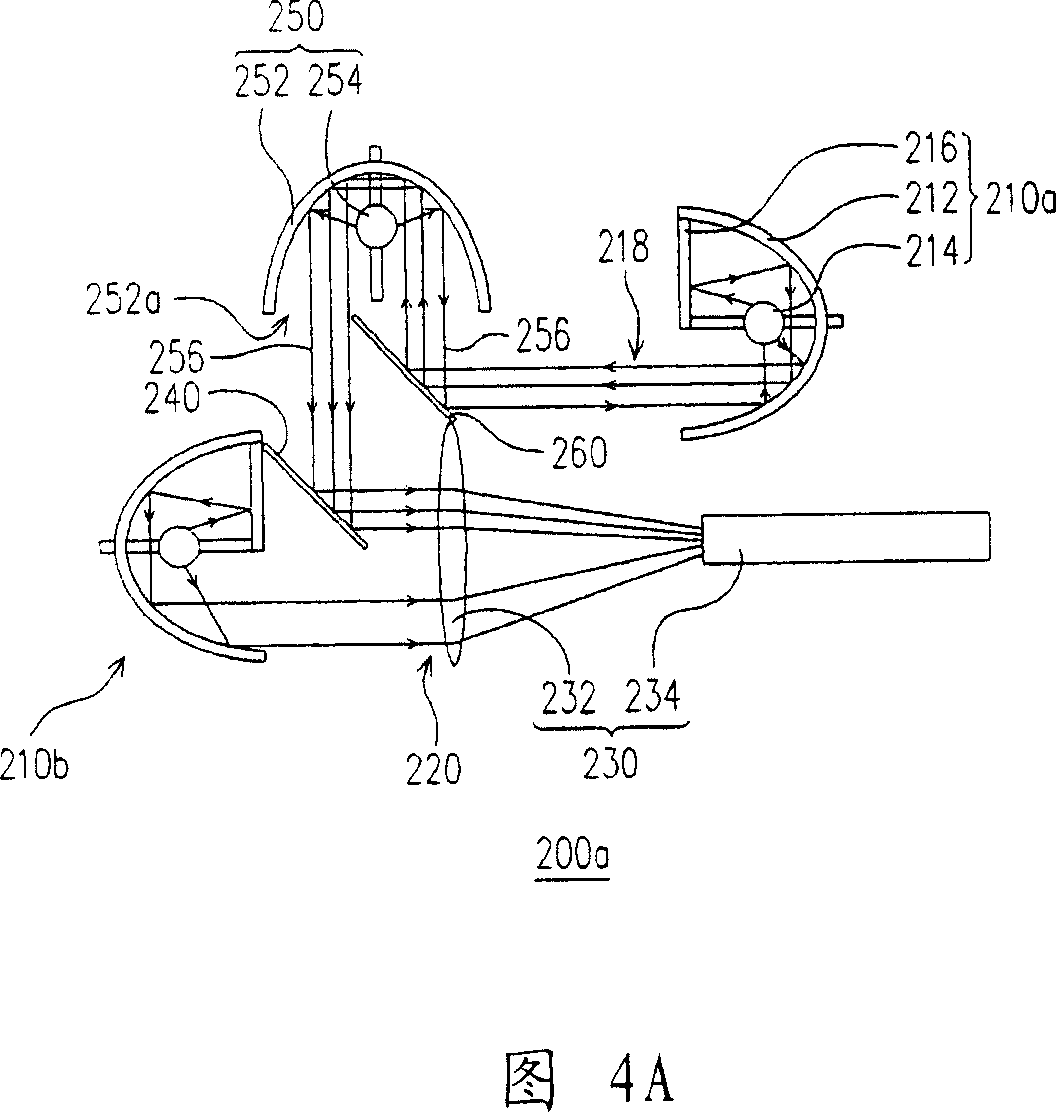

[0051]Referring to FIG. 2, the lighting system 200 of this embodiment includes two first lamps 210a and 210b and a second reflective element 240, wherein the second reflective element 240 is arranged between the first lamps 210a and 210b, and each The first lamps 210 a and 210 b include a first lampshade 212 , a first wick 214 and a first reflective element 216 , and the axes of the first wicks 214 of the two first lamps 210 a and 210 b are arranged to be perpendicular to each other. The first lampshade 212 has a first light emitting section 212a, and the first reflective element 216 is connected to the first lampshade 212 and partially shields the first light emitting section 212a. The first wick 214 is adapted to provide the first divergent light, and the first lampshade 212 and the first reflective element 216 are adapted to form the first divergent light into a first parallel beam 218, and the first parallel beam 218 has never been illuminated by the first reflective elemen...

no. 2 approach

[0063] Please refer to FIG. 6 , the lighting system 200c of the present embodiment is similar to the lighting system 200 of the first embodiment, so the same reference numerals will be used to denote the same components in FIG. 6 . The lighting system 200c of this embodiment includes two lamps 210c, 210d and a reflective element 240' disposed between the two lamps 210c, 210d. Wherein, each lamp 210c, 210d includes a lampshade 212', a wick 214' and a shading element 217. The lampshade 212' has a light emitting section 212a', and the wick 214' is disposed in the lampshade 212', and the light shielding element 217 covers part of the wick 214'. The wick 214' is adapted to provide divergent light, and the lampshade 212' is adapted to form the divergent light into a parallel beam 218', and the parallel beam 218' is output from a part of the light output section 212a'. In addition, the reflective element 240' is located in front of the light emitting section 212a' of one of the lamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com