Traction type super capacity capacitor electric car

A capacitor and traction-type technology, applied in the field of traction-type super-capacity capacitor trams, can solve problems such as accidents, difficult commercial operation, and equipment that are prone to failure, and achieve the effects of stable performance, novel structure, and increased cruising range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

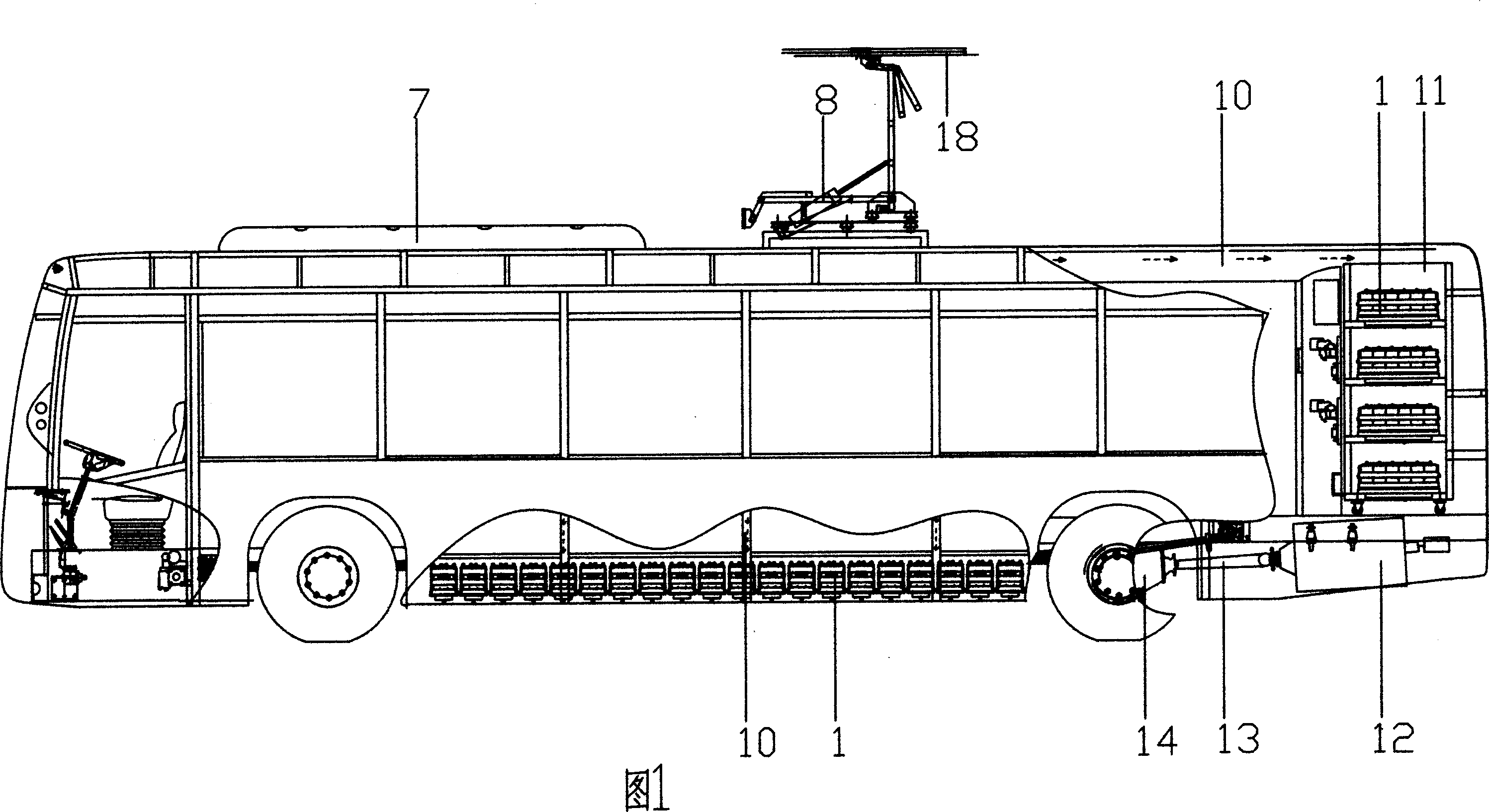

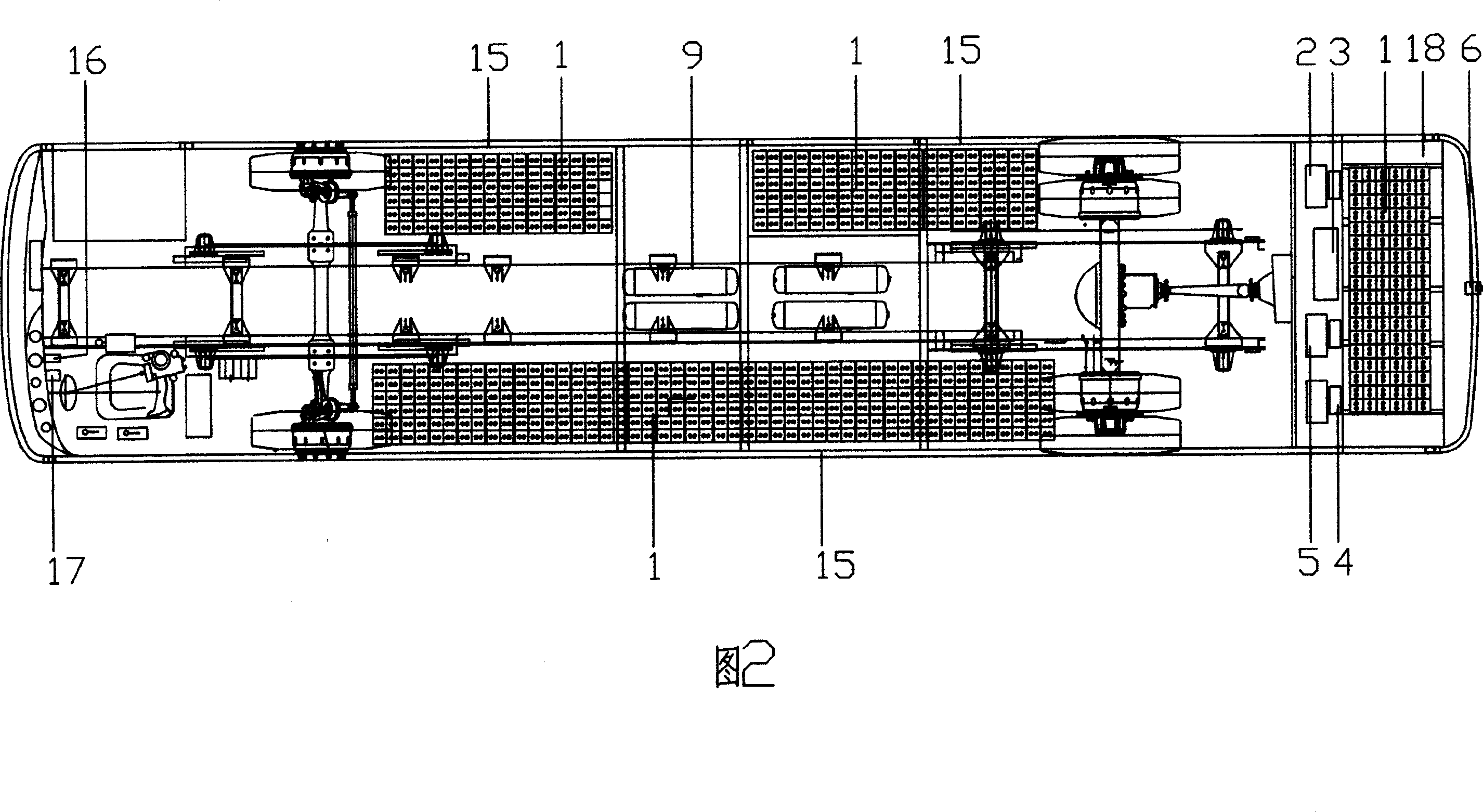

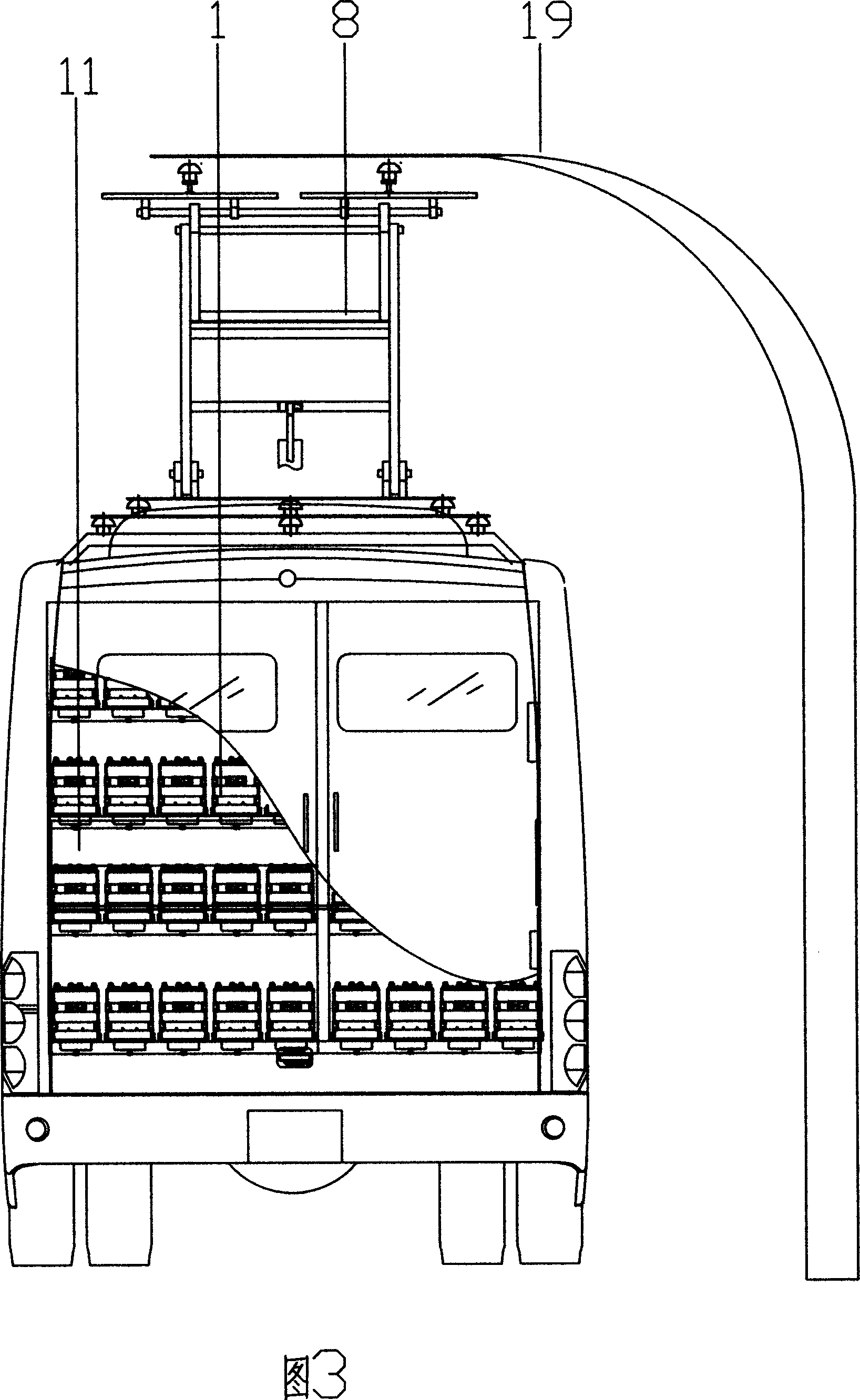

[0016] Below in conjunction with embodiment and accompanying drawing, the present invention is further described:

[0017] As shown in Fig. 1, Fig. 2 and Fig. 3, the traction-type ultra-large-capacity capacitor bank 1 is installed in the capacitor compartment 15 and capacitor compartment 11 on both sides of the tram and at the rear of the tram; The capacitor compartment 15 and the capacitor compartment 11 on both sides of the vehicle deliver cold air so that the temperature in the capacitor compartment does not exceed 25°C; the ground receiving equipment is connected to the receiving contact wire 18 through the receiving bracket 19 and conducted to the flip double contact receiving device 8 through the connection The ECU central controller 2 switcher actuator is connected to the traction-type ultra-large-capacity capacitor bank 1 to supplement electric energy for the energy of the tram; the traction-type ultra-large-capacity capacitor bank 1 is connected to the traction-type sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com