Corrosion resistant multifunctional high-pressure well mouth apparatus

A wellhead device and multi-functional technology, applied in the direction of wellbore/well components, earthwork drilling, sealing/packing, etc., can solve the problems of large power consumption, large consumption of packing, easy corrosion of polished rod appearance, etc., to achieve Effects of preventing uneven wear and shortening replacement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

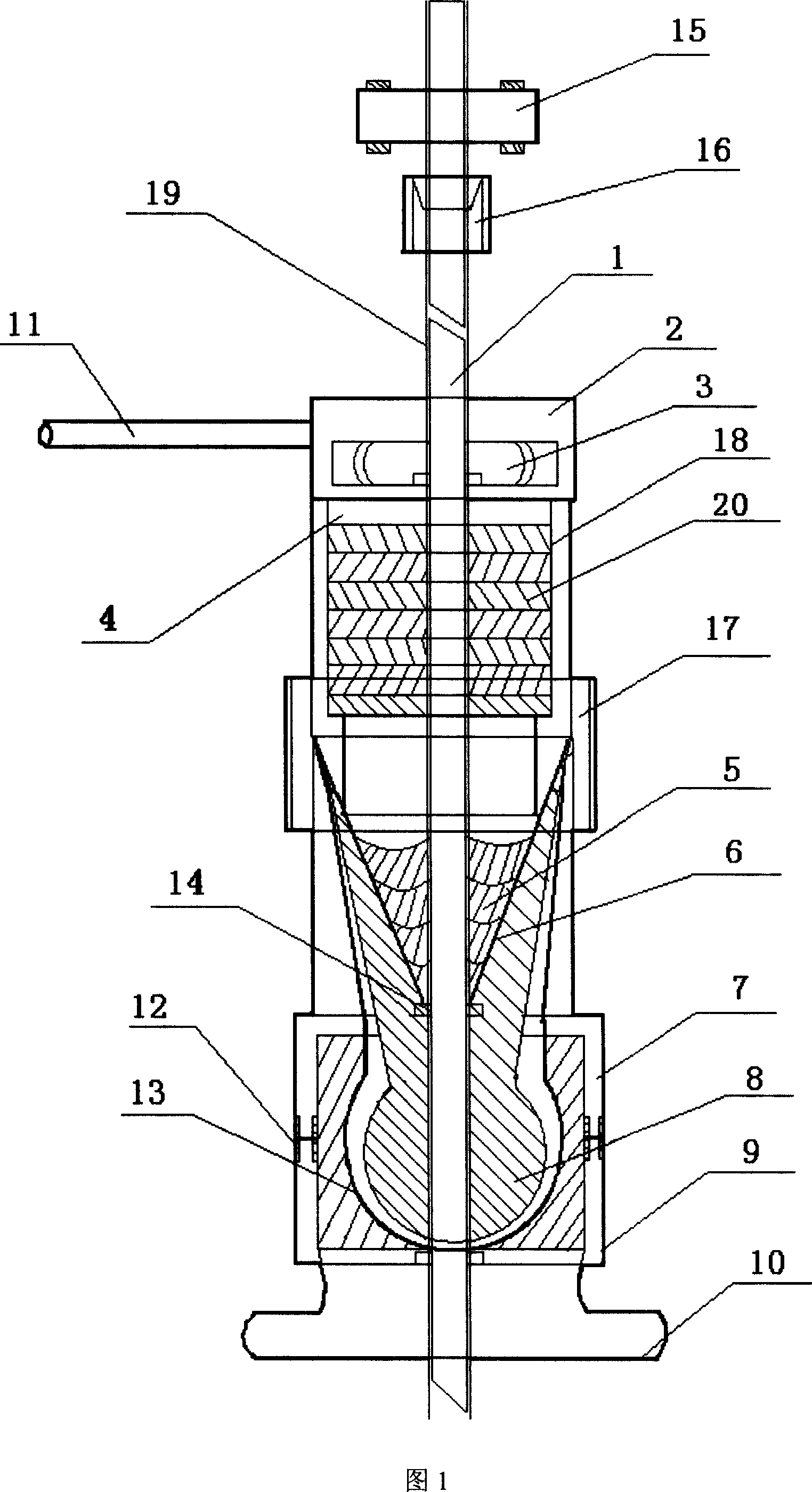

[0013] Referring to accompanying drawing 1, connect spherical base 9, spherical pressing cap 7, two packing cavities 6 and 18, packing pressing cap 4, oil groove 3 and pressing cap 2, rope hanger 15 on the upper end of clamp 10 successively, and polished rod 1 passes through the above components in sequence, and plays the role of centering through the nylon centering sleeve 14; a spherical body 8 is arranged in a spherical cavity formed inside the spherical base 9 and the spherical pressing cap 7, and the packing cavity is composed of the upper packing cavity 18 It is connected with the lower packing cavity 6 through a lock nut 17. The upper packing cavity 18 is a cylindrical structure, and the lower packing cavity 6 is a conical structure. The inner cavities of the upper and lower packing cavities 18, 6 There are multiple packings 5, this structure can effectively ensure that the packing replacement time is shortened, and at the same time meet the requirements of high temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com