Adjustable open double seal guide groove

An open, double-sealed technology, applied in the direction of transportation, packaging, conveyors, etc., can solve the problems of increasing the running resistance of the belt conveyor, heavy load deviation, dust flying, etc., to improve the working environment, adjust the deviation of the belt, The effect of improving the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

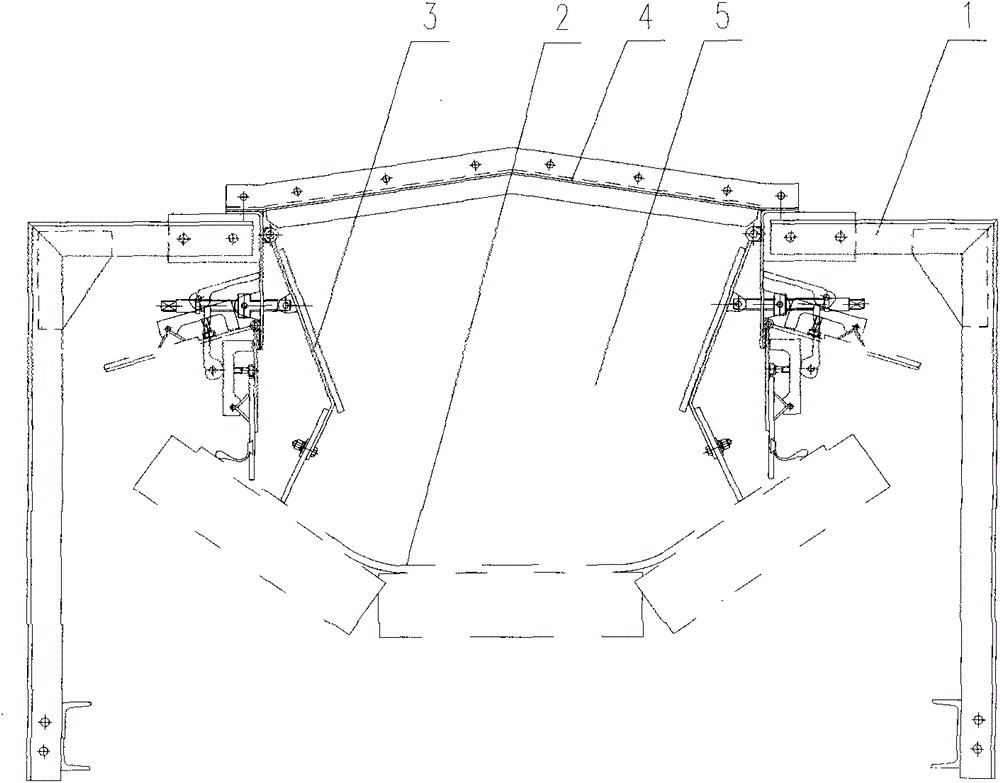

[0020] see figure 1 , an adjustable open type double-seal material guide groove provided by the present invention, comprising a bracket 1, a material guide plate 3 fixed on both sides above the adhesive tape 2 by the bracket 1, and an upper cover connected and installed between the top of the material guide plate 3 4. An inner sealing material flow channel 5 is formed between the adhesive tape 2 , the upper cover 4 and the material guide plates 3 on both sides. This structural design has already appeared in the prior art, and it is much better than ordinary material guide troughs, and has the functions of reducing dust pollution and improving the working environment. In order to solve the problems mentioned in the background technology, to make the material flow direction adjustable, to control the centering of the material flow, to adjust the deviation of the tape, and to facilitate maintenance, the technical solution of the present invention is that the material guide plate ...

Embodiment 2

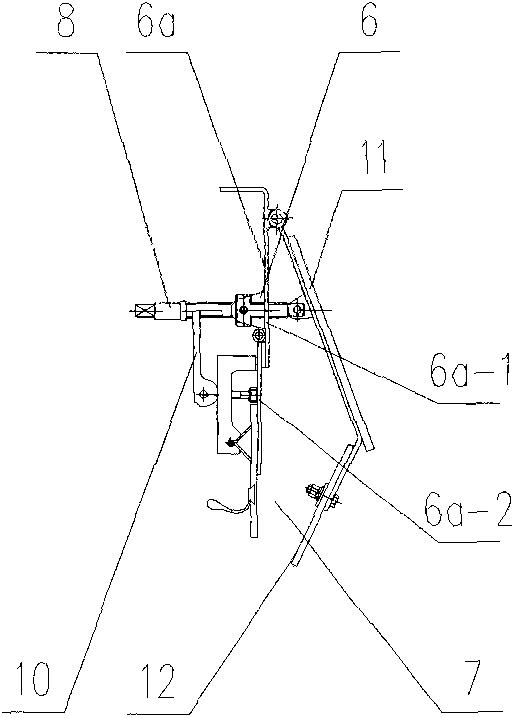

[0023] As a further improvement to Embodiment 1, the purpose is to improve the sealing performance of the outer sealing chamber 7. The outer sealing plate 6a can be designed as a split structure, including an upper sealing plate 6a-1 and a lower sealing plate 6a-1 hinged to it. 2. An anti-overflow skirt 9 is detachably installed on the lower sealing plate 6a-2. By adjusting the pressing device 10 outside the outer sealing plate 6a, the compression of the anti-overflow skirt 9 on the tape 2 is realized to ensure the sealing sex.

Embodiment 3

[0025] As a further improvement to Embodiment 1, a wear-resistant liner 11 (such as alloy, ceramic, polymer, etc.) It can improve its service life and facilitate maintenance and replacement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com