Weight-fixing cutting device of continuous casting blank

A shearing device and continuous casting billet technology are applied in the field of constant-weight shearing devices for continuous casting billets, which can solve the problems of rolling steel sizing rate and finished product rate, and achieve the effect of improving the sizing rate and finished product rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

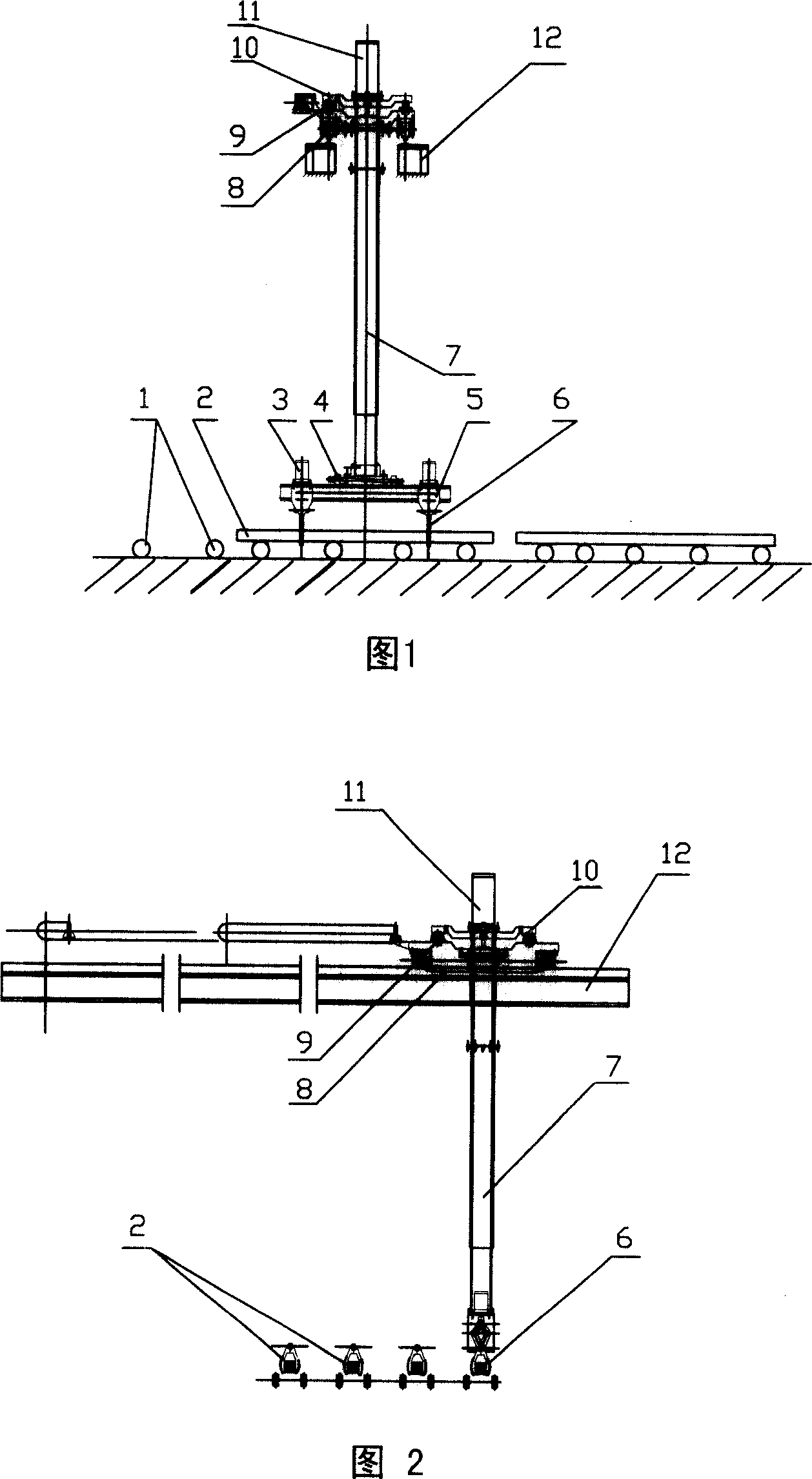

[0008] A continuous casting slab fixed weight shearing device includes a shearing device, a slab roller table 1, a slab flow and a control system. Track beam 12, place mobile trolley 8 on track beam 12, install weighing frame 10 and load cell 9 on mobile trolley 8, be provided with electric push rod 11 on the weighing frame 10, electric push rod 11 links to each other with telescopic rod 7, The end of telescopic link 7 is affixed with shoulder pole beam 5, and hoist 3 and hand joint 6 are equipped with at the two ends of shoulder pole beam 5, and hand joint 6 can grab the billet 2 on the billet roller table 1.

[0009] The control system automatically controls the mobile trolley 8 to be positioned above the slab stream that needs to be weighed according to the requirements, and controls the hand joint 6 to grab the slab 2 to carry out weighing. According to the difference between the weight data obtained by weighing and the target weight, the control system automatically correc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com