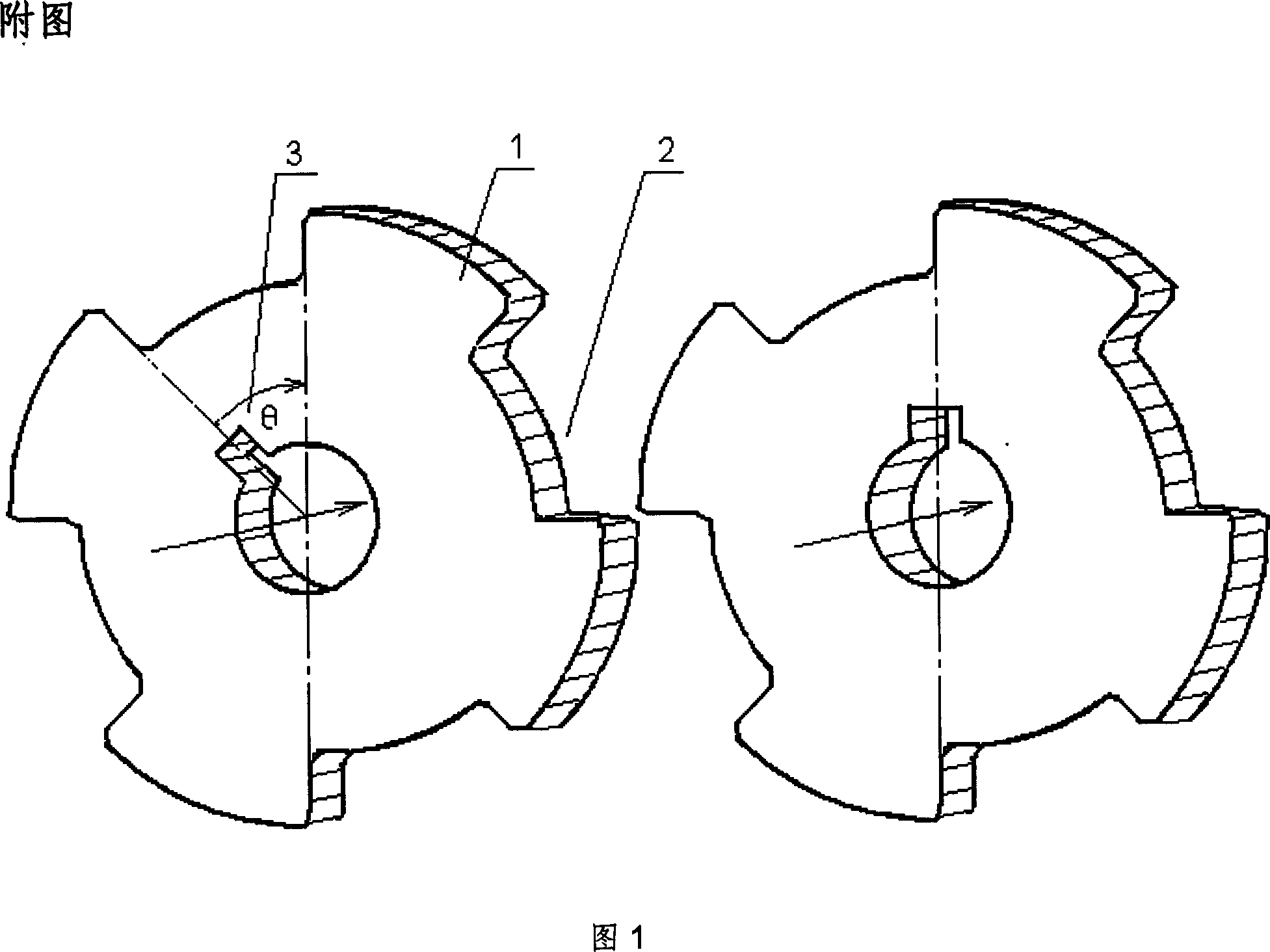

Wide tooth form relay transmission gear and manufacture method therefor

A transmission gear and tooth profile technology, applied in belts/chains/gears, components with teeth, portable lifting devices, etc., can solve the problem of precise design of tooth profile lines and complex manufacturing processes, and difficult to reproduce gear moment strength Double improvement, no major breakthroughs and other issues, to achieve low production costs, conducive to miniaturization and thinning, and less wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

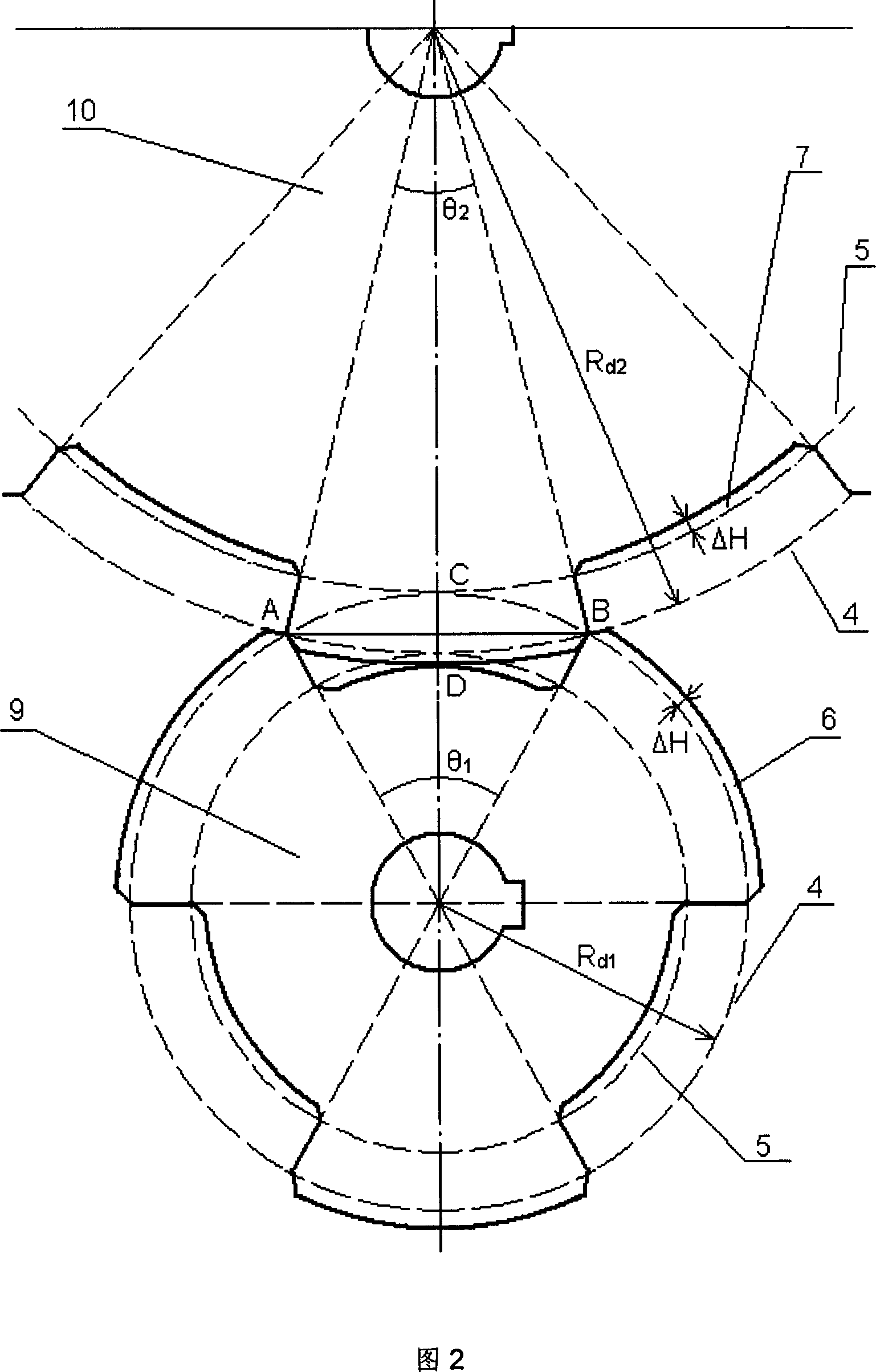

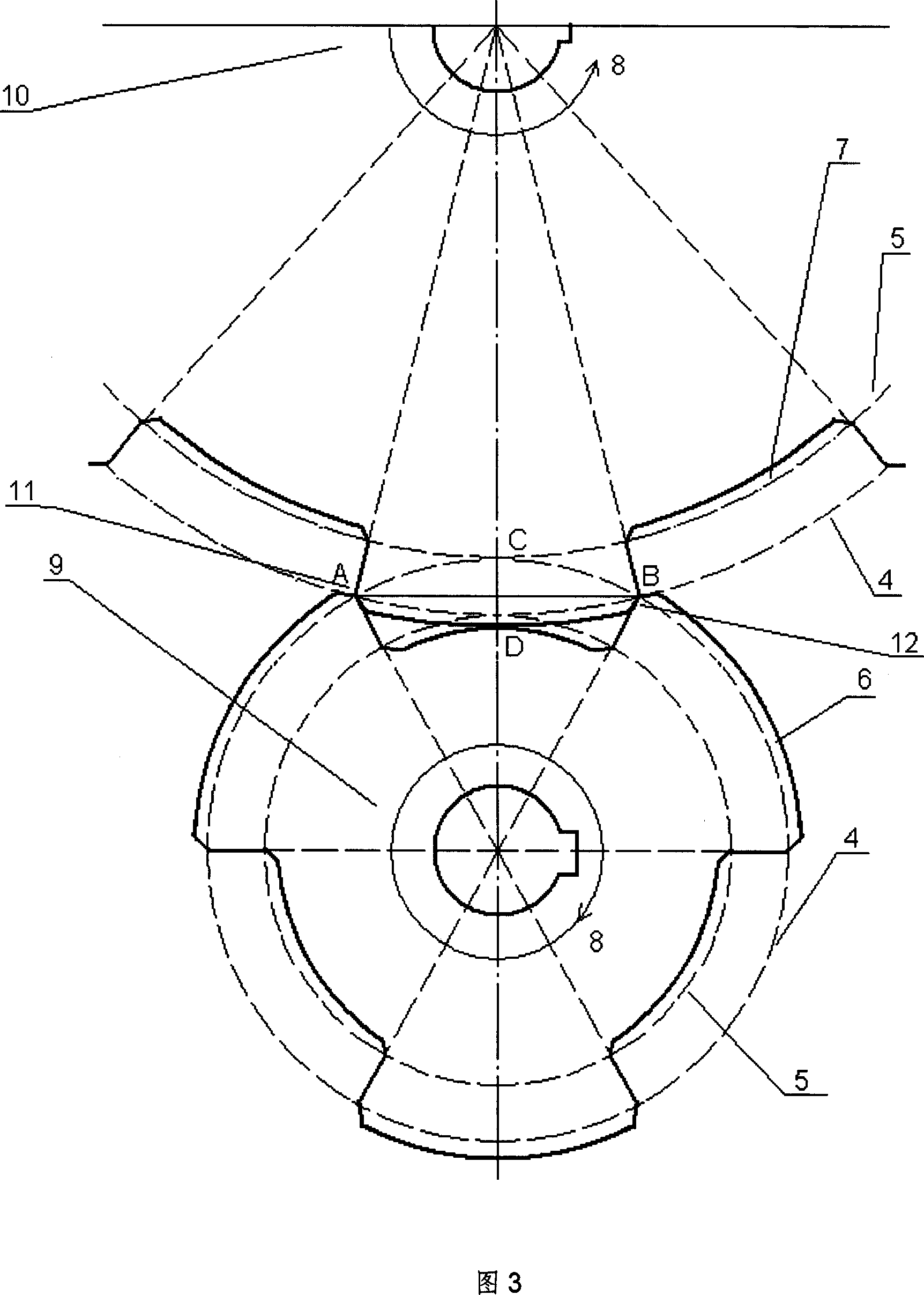

[0025] The specific embodiment of the present invention is described below in conjunction with accompanying drawing:

[0026] (1) Referring to Figure 2, first determine the number of teeth z of the two gears according to the estimated value of the gear diameter and the transmission ratio 1 ,z 2 and the radius R of the addendum circle 4 of the driving wheel or driven wheel d1 or R d2 value.

[0027] (2) by the number of teeth z 1 ,z 2 Directly calculate the central angle 3 corresponding to the tooth end 1 or the dedendum 2, that is, the rotation angle θ that the teeth should be staggered when two gears are coaxially superimposed in the wide-tooth superimposed gear 1 , θ 2 . Or the maximum central angle at which the planetary gears should be staggered when the planetary gears are in continuous meshing transmission. It is also the minimum central angle by which the teeth of wide-toothed helical gears must be rotated and tilted.

[0028] (3) Radius R of addendum circle 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com